How to do a good job of the printed circuit board PTH process, the following Chinese printed circuit board manufacturers for your simple introduction:

Electroless copper plating, also known as plating through hole (PTH), is an autocatalytic REDOX reaction. The PTH process should be carried out after two or more layers of boards have been drilled.

The role of PTH: On the non-conducting cell wall substrate of the borehole, a thin layer of chemical copper deposition is used as the substrate for subsequent electroplating of copper.

PTH process decomposition: alkali degreasing → secondary or tertiary countercurrent rinse → coarsening (micro etching) → secondary countercurrent rinse → prepreg → activation → secondary countercurrent rinse → debinding → secondary countercurrent rinse → sunk copper → secondary countercurrent rinse → pickling.

PTH detailed process explanation:

1. Alkali degreasing: Remove oil stains, fingerprints, oxides and pore dust on the board. The pore wall is adjusted from negative charge to positive charge to facilitate the adsorption of colloidal palladium. After degreasing, it should be cleaned in strict accordance with the guidelines and tested with a copper backlight test.

2. Micro etching: Remove oxide from the surface of the circuit board and roughen the surface to ensure the subsequent copper layer is well bonded to the copper at the bottom of the substrate. The new copper surface has strong activity and can adsorb colloid palladium well.

3. Prepreg: it is mainly used to protect palladium tank from the pollution of the pretreatment tank and prolong the service life of palladium tank. The main components are consistent with palladium tank except palladium chloride, which can effectively wet the pore wall and facilitate the subsequent activation fluid to enter the pore in time for sufficient and effective activation.

4. Activation: after adjusting the polarity of pre-treated alkaline oil removal, the positively charged pore wall can effectively absorb enough colloidal palladium particles with negative charge, so as to ensure the average, continuity and compactness of subsequent copper deposition. Therefore, deoiling and activation are very important to the quality of subsequent sunk copper. Control points: stipulated time; standard tin ion and chloride ion concentrations; specific gravity, acidity and temperature are also important and should be strictly controlled according to the work instructions.

5. Debinding: remove the stannous ions surrounding the colloid palladium particles, expose the palladium nuclei in the colloid particles, and catalyze the chemical precipitation of copper directly and effectively. Experience shows that it is a better choice to use fluoroboric acid as adhesive.

6. Sinking copper: the activation of palladium nucleus induces the autocatalytic reaction of chemical sinking copper, and both the new chemical copper and the reaction byproduct hydrogen can be used as the reaction catalyst to catalyze the reaction, so that the sinking copper reaction can be carried on continuously. After this process, a layer of chemical copper can be deposited on the plate or hole wall. During the process, the tank should be stirred with normal air to convert more soluble bivalent copper.

PTH process quality is directly related to the quality of the production of circuit boards. It is the main source of through-hole and short-circuit processes, and it is not convenient for visual inspection. Post-processing can only be used for probabilistic screening through destructive experiments. Effectively analyze and monitor a single PCB, once there is a problem, there will inevitably be a batch problem, even if the test can not be completed, the final product will cause great quality hazard, can only be scrapped in batches, so strictly follow the parameters of the work instructions.

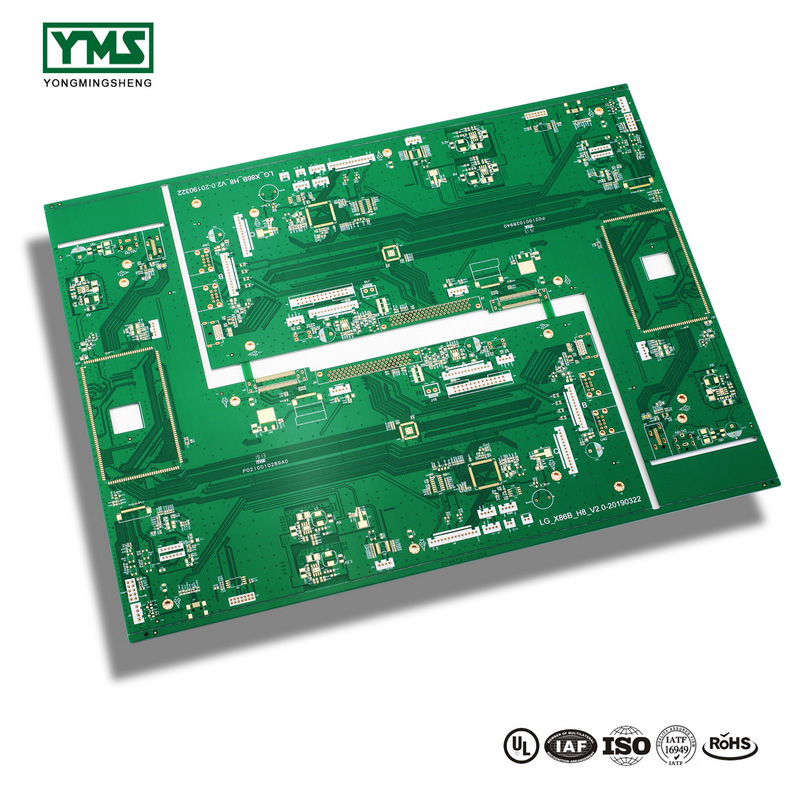

Huizhou Yongmingsheng Technology co., ltd. were successively established. Our enterprise is a high-tech enterprise which professional manufacture and sale high-precision single, double, multi-layer PCB, FPC, metal pcb,Flex-Rigid Board and aluminum base board.

Post time: Nov-26-2019