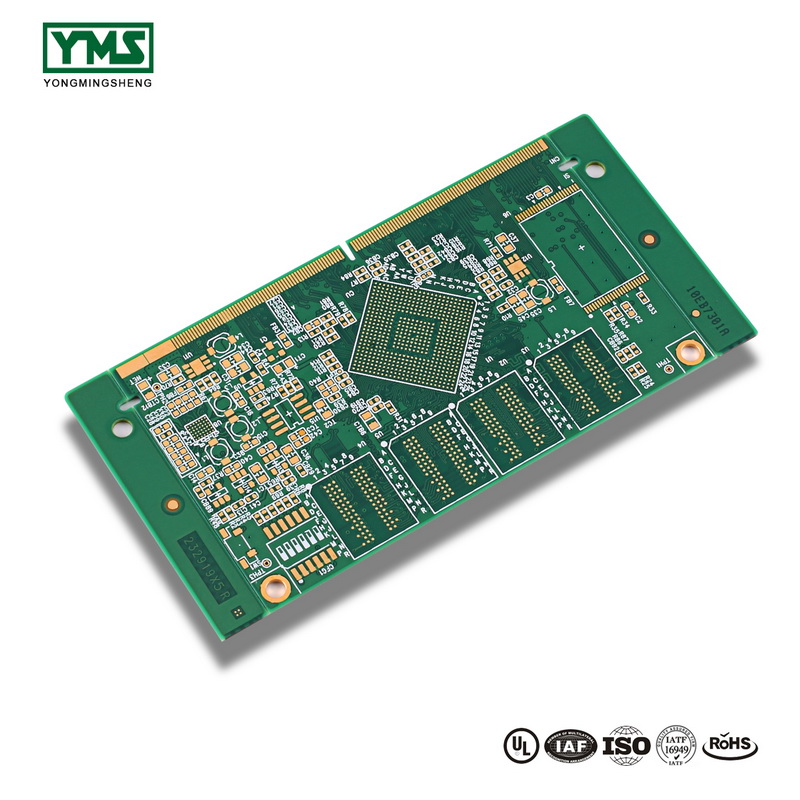

HDI, short for high-density interconnection, is the production of printed circuit boards, which use microblind burrow technology, a circuit board with a relatively high circuit distribution density.

HDI PCB is a compact product designed for small capacity customers. It is designed to be modular and parallel-able, with a module capacity of 1000VA (height 1U), natural cooling, and can be placed directly into a 19 "rack, with a maximum of 6 modules parallel-connected.

The product adopts full digital signal processing (DSP) technology and a number of proprietary technology, with a full range of adaptive load capacity and strong short-term overload capacity, can not consider the load power factor and peak factor.

HDI is a high density interconnect (HDI) manufactured printed circuit board (PCB), which is a structural component formed by insulating material and conductor wiring.

Printed circuit boards are assembled with integrated circuits, transistors (transistors, diodes), passive components (resistors, capacitors, connectors, etc.) and various other electronic components when they are made into final products.

By means of wire connection, electronic signal connection and function can be formed. Therefore, the printed circuit board is a platform for connecting components to form a base for connecting parts.

Printed circuit board is not a general end product, so the definition of the name is a little confused, for example: the PC used by the motherboard, called the motherboard but not directly called the circuit board, although there are circuit boards in the motherboard but not the same, so the industry evaluation of the two related but not the same.

Another example: the news media call the integrated circuit board (IC board) because there are integrated circuit parts mounted on the circuit board, but it is not the same as the printed circuit board in essence.

The electronic design is not only improving the performance of the whole machine, but also reducing its size. From mobile phones to small, portable devices with smart weapons, "small" is a constant pursuit. High-density integration (HDI) technology enables the miniaturization of end product design while meeting higher standards of electronic performance and efficiency.

HDI is widely used in mobile phones, digital cameras, MP3, MP4, laptop computers, automotive electronics and other digital products, among which mobile phones are the most widely used.

HDI board is generally manufactured by the laminated method. The more times the laminated, the higher the technical level of the plate. Ordinary HDI boards are basically one-time stacking, while high-order HDI adopts two-time or more stacking technology, and adopts advanced PCB technologies such as hole stacking, hole filling by electroplating and direct drilling by laser. HDI board is mainly used in 3G mobile phones, advanced digital cameras, IC board and so on.

You May Like:

Post time: Sep-23-2019