China PCB manufacturer tells you

The main function of PCB copper cladding is "backflow and shielding".

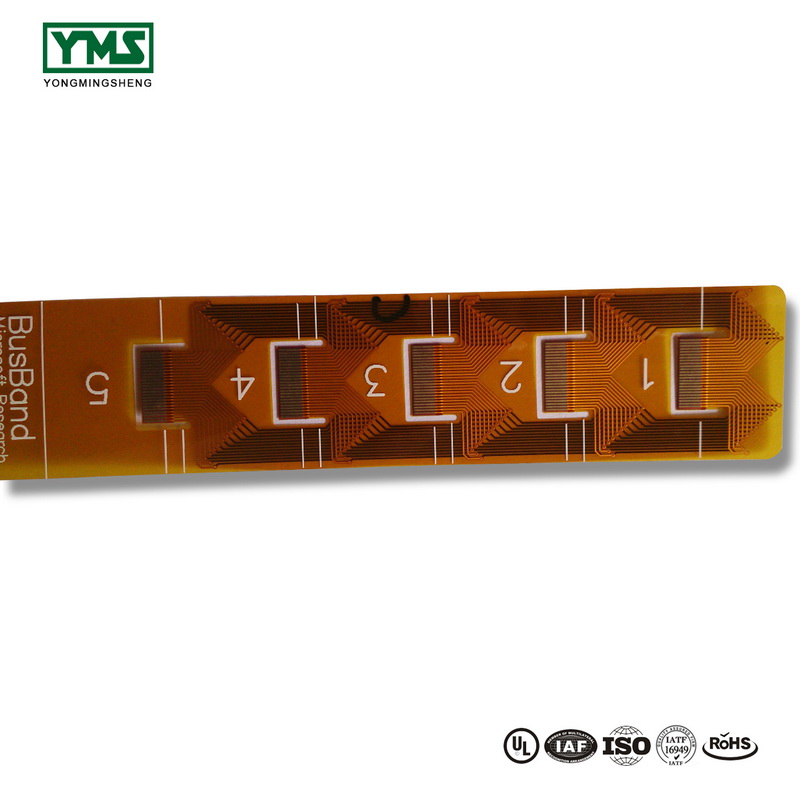

PCB copper cladding is mainly carried out by means of grid.

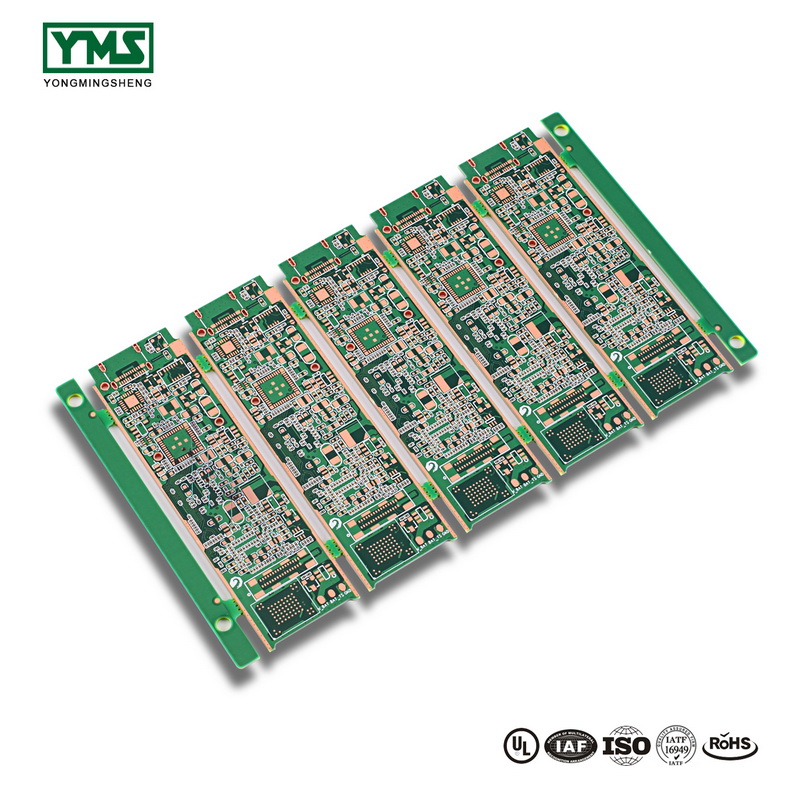

Double-layer PCB with copper cladding thickness of about 35um (1.4mil); 50um is uncommon;

The surface layer of multi-layer PCB with copper caldding is 35um (1.4mil) and the inner layer is 17.5um (0.7mil).

PCB copper cladding thickness is also indicated in OZ (OZ).

The advantages of PCB copper cladding are "improving power efficiency, reducing high-frequency interference and improving aesthetics".

Tell so much knowledge of PCB copper cladding, then what are PCB copper cladding skills and settings? Yongmingsheng PCB factory is now going to introduce the technique and setting of PCB copper cladding.

PCB copper cladding technique:

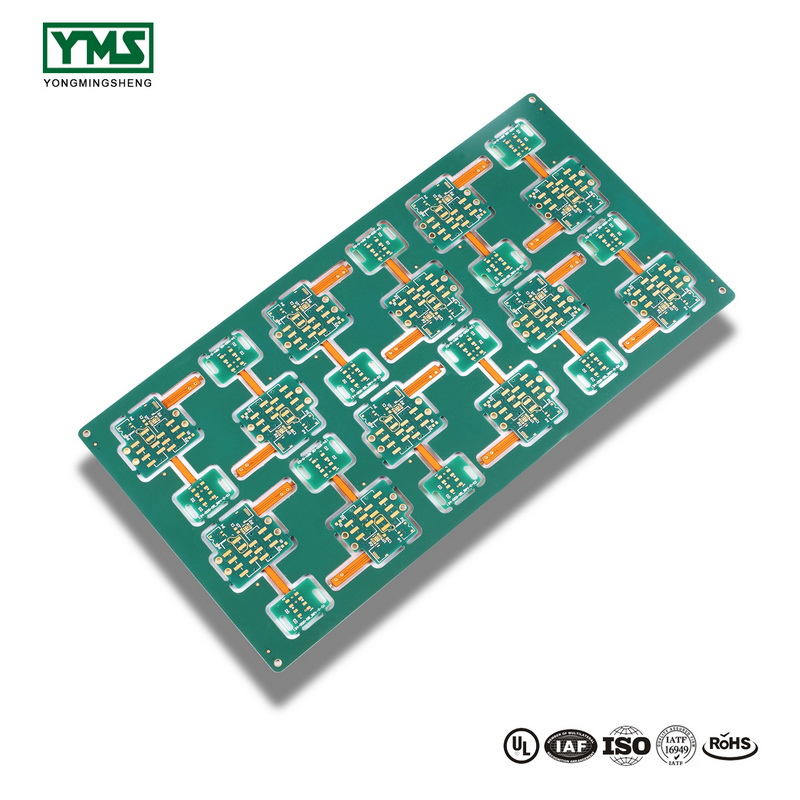

1. If the PCB has more "grounding" such as SGND, AGND, GND, etc. According to the position of PCB board, the most important "grounding" will be used to as the separated copper. At the same time, when the digital and analog is naturally to separate to cover the copper, first the corresponding connection power cords like 5.0 V or 3.3 V, etc. should be added before cladding copper. In this way, multiple deformation structures of different shapes are formed.

2. For single point connection at different locations, the method is to connect through 0 ohm resistance or magnetic bead or inductance connection.

3. Covering copper near the crystal oscillator. The crystal oscillator in the circuit is a high-frequency transmitting source. The method is to lay copper around the crystal oscillator, and then ground the shell of the crystal oscillator separately.

4. Island (dead zone) problem, if you feel very big, then define a hole to add, it does not cost much.

5. In the beginning of wiring, should be treated as the same ground wire, and the wire should be good, can not rely on copper after adding holes to eliminate as a connection pin, this effect is very bad.

6. It is best not to have a sharp angle on the board, because from the point of view of electromagnetism, this constitutes a transmitting antenna! For others, there will always be an impact is just big or small, I suggest using the edge of the arc along the edge.

7. Multi-layer board middle layer wiring empty area, do not cover copper. Because it's hard for you to make this copper "well grounded."

8. The metal inside the equipment, such as metal radiator and metal reinforcement strip, must be "well grounded".

9. The cooling metal block of the three-terminal regulator must be well grounded. And the ground isolation belt near the crystal vibration must be well grounded.

In a word, the copper cladding of the PCB, if the grounding problem is properly handled, the copper coating on the PCB will definitely bring more advantages than disadvantages. It can reduce the backflow area of the signal line and reduce the external electromagnetic interference of the signal.

You May Like

Post time: Dec-20-2019