Because printed circuit board is not a common end product, the definition of the name is a bit confusing.For example, the main board of a personal computer is called the main board, not the circuit board directly.There’s a circuit board on the motherboard, but it’s different, so when you’re evaluating the industry, you can’t say the same thing.

For example, because the integrated circuit components are mounted on the circuit boards, the press calls them IC boards, but in essence they are not equivalent to printed circuit boards.We usually refer to a printed circuit board as a bare board – a circuit board that has no upper components.In the process of PCB board design and PCB board production, engineers not only need to prevent PCB board from accidental encounter in the manufacturing process, but also need to avoid design errors.

Common PCB faults and their causes

1. Circuit board short circuit:

For such problems, one of the common faults that directly lead to circuit board work, the biggest reason is that the PCB short circuit is the improper design of the solder pad.At this point, the circular pad can become an ellipse.Shape to increase the distance between points to prevent short circuit.

Improper design of PCB proofing parts will cause circuit circuit and failure to work.If SOIC’s feet are parallel to the tin wave, it is easy to cause a short circuit accident.

In this case, the direction of the component can be changed to be perpendicular to the sn wave.PCB may also short circuit, that is, the automatic plug-in bending.As the IPC stipulates that the length of the wire is less than 2mm, when the bending Angle is too large, this part may drop, so it is easy to cause short circuit, and the welding point needs to be larger than 2mm offline.

2. The PCB solder joint turns golden:

Generally, the solder for PCB boards is silver gray, but occasionally there is a gold solder spot.The main reason for this problem is that the temperature is too high.

3. Black and granular contacts on the circuit board:

Dark or small particle contacts on PCB are mainly due to solder contamination and excessive oxide in tin, resulting in too fragile solder structure.Care must be taken not to confuse the dark and low tin content caused by the use of solder.

Another cause of this problem is the change in composition of the solder used in the manufacturing process and the excessive amount of impurities, requiring the addition of pure tin or replacement of solder.The colored glass ACTS as a physical change in the layers of the fibers, such as the separation between the layers.But that’s not a bad spot.The reason is that the substrate heating is too high, need to reduce the preheating and welding temperature or increase the substrate speed.

4. Loose or misaligned PCB components:

During reflow soldering, the widget may float on the molten solder and eventually fall off the target solder joint.Possible causes of displacement or tilt include vibration or rebound of components on the welded PCB due to insufficient support of the circuit board, reflow furnace setup, solder paste problems, and human error.

5. Open circuit board:

An open circuit occurs when the trace line breaks or when the solder is only on the pad and not on the component lead.In this case, there is no glue or connection between the component and the PCB.Just like short circuits, these can occur during production or during welding and other operations.Shaking or stretching the board, dropping the board or other mechanical deformation factors can damage the board or solder joints.

In addition, chemicals or moisture can cause solder or metal parts to wear out and cause component wires to break.

6. Welding problems:

The following are some problems caused by poor welding:

Interference with solder joints: solder moves due to external interference before solidification.This is similar to a cold weld spot, but for different reasons can be corrected by reheating, and the welded joint is cooled without external interference.

Cold welding: this occurs when the solder does not melt properly, resulting in rough surfaces and unreliable connections.Cold solder joints can also occur because excess solder prevents complete melting.The solution is to reheat the joint and remove the excess solder.

Welding bridge: this occurs when the solder crosses and physically connects the two leads.These can cause unexpected connections and short circuits, which can cause components to burn out or break wires when the current is too high.Pads, needles or lead are not wet enough.Too much or too little solder.A solder pad that bulges due to overheating or rough welding.

7. The disadvantages of PCB board are also affected by the environment:

Due to the structure of the PCB itself, it is easy to damage the circuit board when it is in an unfavorable environment.Extreme temperature or temperature variation, other conditions such as high humidity and high intensity vibration are factors that lead to reduced or even scrapped circuit board performance.For example, changes in ambient temperature can lead to circuit board deformation.This can damage solder joints, bend the shape of the circuit board, or cause copper wires on the circuit board to break.

On the other hand, moisture in the air can cause oxidation, corrosion, and rust on metal surfaces, such as exposed copper trace lines, solder joints, pads, and component leads.Dirt, debris or debris that builds up on the surfaces of components and circuit boards can also reduce air flow and component cooling, resulting in overheating and poor performance of the PCB.Vibration, drop, impact, or bending of the PCB can cause the PCB to deform and crack, while high current or overvoltage can cause PCB damage or lead to rapid aging of components and paths.

8. Human error:

Most defects in PCB manufacturing are caused by human error.In most cases, incorrect production processes, incorrect placement of components and unprofessional manufacturing specifications result in up to 64 percent of avoidable errors.Product defect occurs.

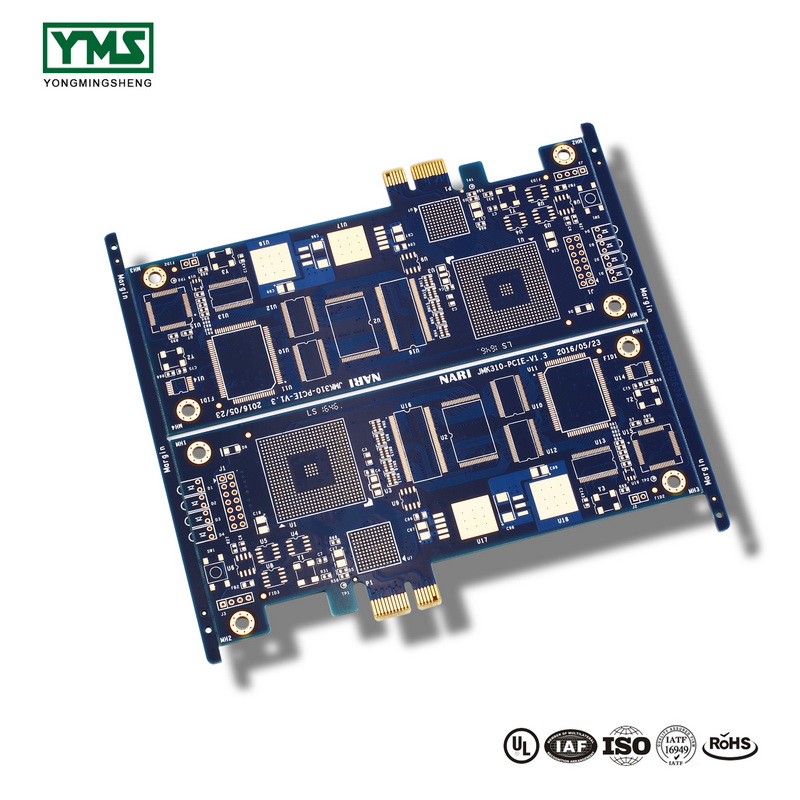

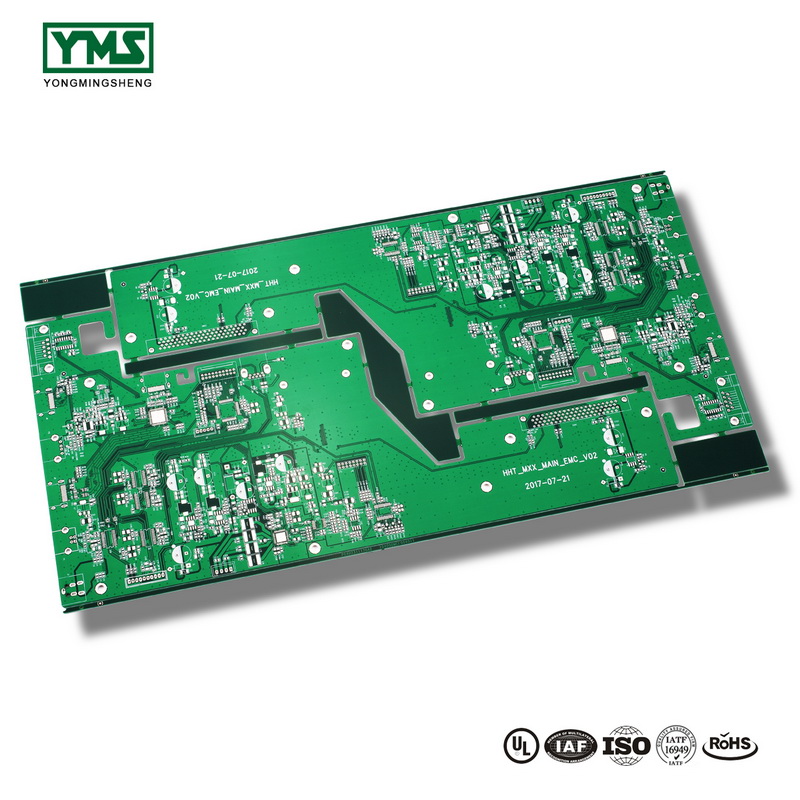

Above is the introduction of common PCB board faults. We are a PCB manufacturer in China, and our products are: HDI board, gold fingers PCB, heavy copper PCB, etc., welcome to consult ~

Post time: Apr-18-2020