Flexible Circuit Manufacturer-China PCB fabrication low cost | YMSPCB

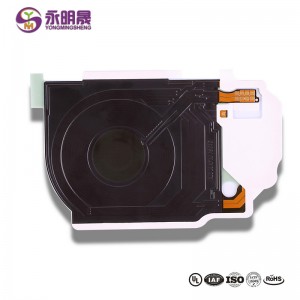

Flexible Printed Circuit Design Advantages

The fact that a flex can be bent, folded and configured in just about any shape or thickness imaginable gives the designer tremendous options when creating an electronics package. Size and space limitations are far less of an issue than traditional design using hardboard circuits. Assembly and handling costs can be significantly decreased because the entire interconnect system can be built as one integrated part. Add All Flex’s ability for component assembly and testing and the supply chain management becomes greatly simplified.

This tremendous flexibility in design choices leads to electronic packages being smaller, lighter and more functional.

Static Application –

An application where flexible circuits are flexed only to install the circuit and fit it into its application (also known as flex-to-install).

Dynamic Flexing Applications –

A situation where the flexible circuit itself is dynamically (repeatedly) flexed during the actual use of the final product. Common examples include flip-type cell phones, laptops, printer heads and robotic arms. A dynamic application will require a very symmetrical material stack up and fully annealed copper conductors.

We've got you covered for both prototype and production quantities.

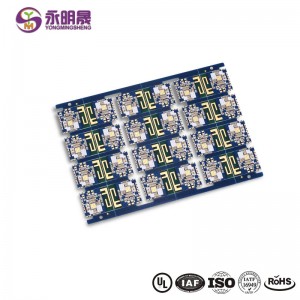

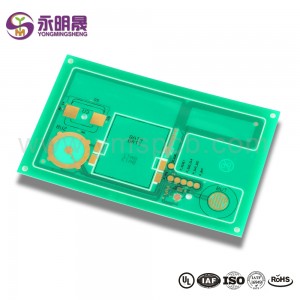

With Flex PCB, you skip the PCB brokers and go straight to the source. Start prototyping in our Chinese facility or directly where your production run will be in China (one of our two Flexible PCB manufacturing facilities in China). This allows you to know what materials and components are most effective during large volume PCB fabrication runs.

It's not just our design and prototype-to-production manufacturing capacity that makes Flex PCB different; our technical, engineering, procurement and customer services gives us a competitive advantage.

Do you need inventory stocking for your flex or rigid-flex PCBs? Get pull and push inventory that meets your specific needs. Order in high volume, but let us manage your inventories with JIT (Just in Time) deliveries.

We also provide flex and rigid-flex PCB assembly services that reduces your vendor count, production delays, and quality issues. From single component to complicated box builds, let Flex PCB do your component sourcing, assembly, and testing.

Capacity

| No. | Item | Process Capability Parameter |

|

1 |

PCB Type | Els PCB flexibles |

|

2 |

Quality Grade | Standard IPC 2 |

|

3 |

Material | PI, PET |

|

4 |

Number of Layers | 1 Layer, 2 Layers, 4 Layers, 6 Layers, 8 Layers |

|

5 |

Max PCB Size | 1 Layer: 4000mm*240mm2 Layers: 800mm*240mmMulti-layers: 350mm*240mm |

|

6 |

Board Size Tolerance(Outline) | ± 0,1 mm |

|

7 |

FPC Thickness | 0,08 ~ 0,4 mm + |

|

8 |

TPC Thickness Tolerance | FPC Thickness≤0.3mm: ±0.03mmFPC Thickness>0.3mm: ±10%~15% |

|

9 |

Types of Copper Foil | Rolled Copper Foil/Electrode Posited Copper |

|

10 |

Copper Thickness | 0.5oz, 1oz, 1.5oz, 2oz |

|

11 |

Min Tracing/Spacing | ≥2mil |

|

12 |

Grid line Tracing/Spacing | ≥0.1mm |

|

13 |

Soldering Pad Diameter | ≥0.3mm |

|

14 |

Quality Grade | Standard IPC 2 |

|

15 |

Lead Time | 5-7 days |

|

16 |

coverlay | Yellow, White, Black, None |

|

17 |

Coverlay Opening Size | ≥0.6mm*0.6mm |

|

18 |

Min Spacing Colverlay to Soldering Pad | ≥0.15mm |

|

19 |

Soldermask Color | Green and others |

|

20 |

Soldermask Bridge | Green: ≥0.1mmOthers: ≥0.15mm |

|

21 |

Min Width of Soldermask and SolderingPad | Green: ≥0.08mmOthers: ≥0.2mm |

|

22 |

serigrafia | White, Black, None |

|

23 |

Minimum Character Width (Legend) | ≥0.8mm |

|

24 |

Minimum Character Height (Legend) | ≥0.8mm |

|

25 |

Min Spacing from Silkscreen to SolderingPad | ≥0.2mm |

|

26 |

Acabat superficial | ENIG, OSP, Immersion Tin, Chemical Silver |

|

27 |

control de la impedància | Single-ended 50Ω, Differential Pairs100Ω, Tolerance ±10% |

|

28 |

Material de reforç | PI, FR-4, Aluminum, Steel, Copper |

|

29 |

Stiffener Thickness | 0.1~0.5mm |

|

30 |

Edge Rail Width | ≥10mm |

|

31 |

Other Options | 3M Tape, EMI Shielding Film |

|

32 |

certificació | ISO9001, RoHS |

Us pot agradar:

1、Sobre la prova normal de FPC i les instruccions de prova urgent

2, Discussió sobre qüestions que necessiten atenció de la placa de circuit flexible FPC

3, disseny de la placa suau FPC ha de prestar atenció al problema

Obteniu més informació sobre els productes YMS

Vídeo

1. Què és un PCB en un cotxe?

Les plaques de circuit imprès són les que mantenen units tots els sensors exquisits i els components necessaris per al funcionament constant d'un vehicle d'automòbil. ... Els fabricants de PCB han d'estar qualificats amb la norma ISO/TS 16949, que es basa en l'estàndard d'automoció ISO 9001.

2. On van els PCB als automòbils?

La llista continua amb els elements crucials com la unitat de navegació, el sistema d'entreteniment i el control del clima. La creixent indústria de l'automòbil elèctric requereix PCB dissenyats especialment per gestionar l'eficiència del combustible o els sistemes de gestió de bateries.