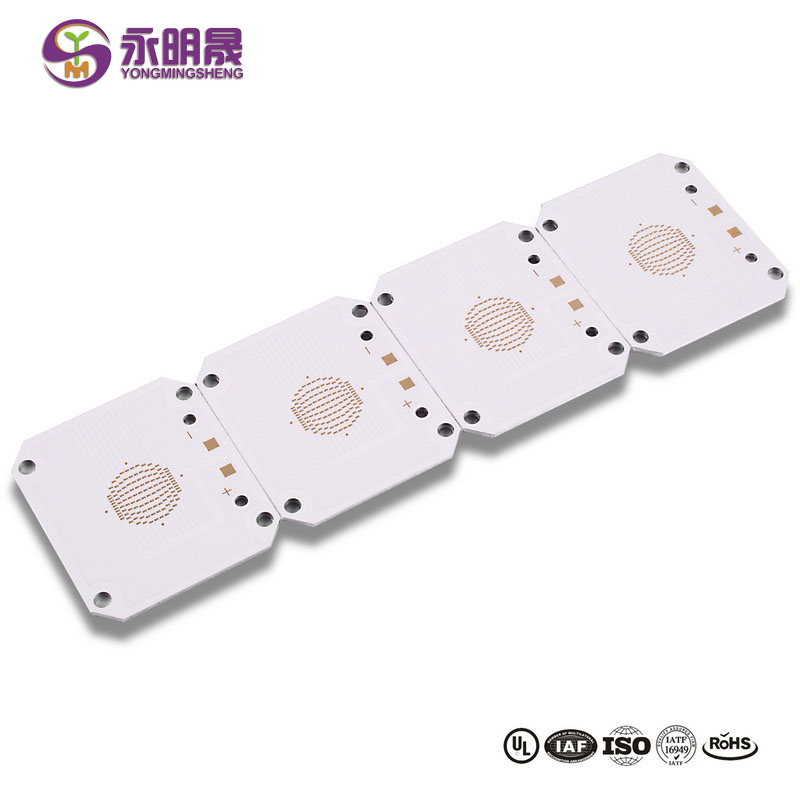

Single-Sided PCB Manufacturer in China

Single-sided PCB, called also 1 layer PCB, refers to a printed circuit board that has one layer conductive pattern.

Single-sided PCB is the simplest and most common PCB. Most PCB manufacturers can produce it.

YMSPCB single-sided circuit board is one of the most cost-effective PCBs in the market, We can provide a quick-turn service for your prototype and mass production.

As a reputable single-sided PCB supplier and factory in China, YMSPCB can offer you many types of single-sided PCBs, including the LED circuit board, flexible circuit boards, aluminum PCB, ceramic PCBRogers printed circuit board, thick copper PCB, high-frequency circuit board, high TG PCB, and TeflonPCB.

Are you looking for a premier single-sided PCB manufacturer? YMSPCB is your best choice.

t can use many different applications including LED lighting, printers, cookers, relays, and camera systems. timing circuits, power supplies, and calculators

YMSPCB can always meet your needs and provide top-quality single-sided PCB to you.

Throughout over 12 years of PCB manufacturing experience, YMSPCB has become the most valuable single-sided PCB supplier in China. We have a professional sales team and an expert engineering team, so you can 100% ensure that YMSPCB can deliver you the best single-sided PCB.

YMSPCB has more than 300 employees with over 12 years of PCB manufacturing experience and the workshop area will be reached 20,000 square meters.

Choose Your Single-sided PCB

We put at your disposal our know-how for the most complex printed circuit designs with parameters or characteristics so special that they require the personal assistance of our team. We will provvide customized solutions that meet your needs simply by sending us your files by e-mail.

Single-Sided PCB: The Ultimate FAQ Guide

A Single Sided PCB is the most basic type of printed circuit board. It consists of only one conductive copper layer above the substrate. The electrical components are soldered or mounted on to one side of the board and the entire etched circuit can be seen on the other side of the board.

Single Sided Printed Circuit Boards are easy to design and manufacturer. They are also the most cost-effective PCBs.

Since these boards have only one conducting layer the conductive paths cannot cross or overlap and thus tend to take up a large amount of space. Due to this such PCBs are ideal for low-density design requirements.

Design

Poor design happens to be a major reason why single-sided PCB fails. When you don't fully understand the specifications of the board and design it to suit these specifications, the board may end up failing.

This means you need to spend time understanding the board's specifications and its working environment. This will help you to create a quality board to meet its operational requirement.

lt will also help you to choose the right materials for the board.

With this said, quality and industry-standard design software should be used for designing for excellent results.

After designing, the design should be checked and verified by an expert before fabrication begins.

Environment

Another common cause of single-sided PCB failure is its working environment. lf the board is exposed to dust, high humidity, and extensive heat, it can fail.

The board should only be used in a suitable environment that aligns with its specifications. lt should be periodically checked, cleaned, and maintained.

Manufacturing Defects

When there are poor or low-quality joints on the board, it can easily fail. Exposure to contaminants during manufacturing can lead to board failure.

Also, when the various layers or components of the single-sided board are not well aligned, it can cause itto fail.

Ensure that soldering is done perfectly to make the joints strong. Do not expose the board to various contaminants when assembling the parts.

The parts should be well aligned. Ensure there is structural integrity when assembling. Strictly follow standard industry fabrication standards to produce quality and lasting single-sided boards

Professionalism

The first thing to look out for in a manufacturer is their professionalism. Your ideal single-sided PCB supplier should be professional in their operations.

One way to check if a manufacturer is professional is their certifications. Ensure you only order from a manufacturer with recognized industry certifications.

Experience

-experience is key in selecting a good single-sided manufacturer. Get to know the experience of the manufacturer in the board manufacturing industry. An ideal manufacturer should have at least 10 years of experience under their belt.

Experienced manufacturers employ experts, an experienced workforce, and the best technology in their board's manufacturing thereby ensuring they offer quality single-sided boards.

Manufacturing technology

Due to the complexity of the manufacturing process of PCB, manufacturers need to use advanced technology and equipment to produce quality board.

This is why you need to find out from the manufacturer's website the kind of technology, equipment, and processes they use.

A reliable single-sided manufacturer should use cutting-edge technologies and test equipment for their production.

Warranty

Again, the complexity of the PCB manufacturing process exposes it to unexpected failure and breakdown. This is why it is always safe to purchase from a supplier that offers at least a 1-year warranty for their board.

Suppliers who offer warranties for their board show they have massive faith in the capabilities of the board. lt also proves they're willing to replace or maintain your board for you for free when it breaks

down during the warranty period.

Below are the processes you need to follow when ordering your single-sided PCB

Determine the specifications of your single-sided board. Depending on the application of your board you need to decide on the specifications of the board before attempting to order for your board. Search for a reliable single-sided PCB. To do this, you can do a quick research on Google or Bingo by entering the keyword"single-sided PCB manufacturers” Pick a Manufacturer with massive experience, at least 10 years. The supplier should use highly advanced equipment for their manufacturing.

Browse the website of your chosen supplier and select your preferred single-sided board that meet your application specifications. You can do this in the product catalog section of the supplier.Connect with the supplier to make a former order request using the order form on their website. Contact the customer services of the supplier for further instructions for your order.

Altium software

Fusion 60

Design spark softwareEagle software

AutoCAD software

PADS PCB design software

Extended Gerber software

Proteus software

Sprint layout software

CAD designing software

Production time for single-sided PCB is influenced by several factors. So, because of this manufacturers have different production times.

With that said, on average, it takes 3-5 to produce samples and 5-7 days for mass-producing single-sided boards.

To massively reduce production and delivery time, you need to produce the board in stock. The manufacturer needs to negotiate and agree with you on the delivery time.

Manufacturers employ various techniques and steps in maintaining single-sided PCB

In this section, we will look at some of the most important and popular steps in maintaining aboard.

Observe the board

For effective maintenance of the board, you need to first observe and understand the board. Critically study the board to understand how it works, its input and output interfaces, the functions it executes and how its different control components are distributed.

Perform a Circuit Test on the Board

Right after critically observing and analyzing the board, you need to do an initial inspection and test on the board.

Even though this initial test may not help you find the real fault of the board, it is super important in providing you with good information that will help you repair the board.

Inspect the Components

Here, you remove the parts of the single-sided board from the circuit with a soldering iron and inspect them with standard inspection equipment.

lt is important to note that it is not advisable to dismantle and remove the board's components under normal circumstances. This is because dismantling the components may lead to damages to the board's external integrity.

Fix the Fault

This is where you do the real maintenance work once you've discovered the board's fault from the first steps. Here, you can repair the lines and replace faulty parts.

Test the board.

After maintaining the board, you need to test it on a computer to make sure it functions as expected.

Single-sided PCB Manufacturers mostly use foil-clad and copper-clad laminates to produce single-sided PCBs.

Copper-clad, copper-clad phenolic paper, and copper-clad epoxy paper laminates are typical examples of materials used for manufacturing single-sided PCB.

When choosing the materials for your board, you need to consider key factors like electrical performance. feasibility, and processing specifications of the board. You need to also take note of the economic features of the board.

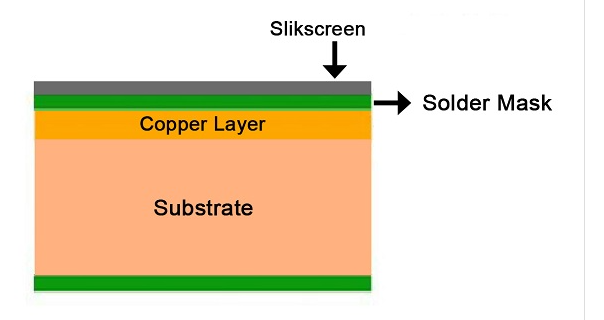

There are four main components of the single-sided PCB. They are substrate, a copper layer, and solder mas silkscreen.

Substrate

The substrate is mostly made of fiberglass and forms the base foundation of the single-sided PCB. provides massive strength to the board. All other layers are built on the substrate. You can call the substrate the main structure of the single-sided PCB.

Copper Layer

The copper conductive layer is applied to the substrate. The board's circuit design is crafted on the copper layer. lt also serves as a medium that transmits signals to other parts of the board. This functions like the nervous system of the human brain that transmits signals to all body parts.

Solder Mask

This polymer material covers the copper layer and soldered sections of the board. The covering of the copper layer with solder masks ensures the board's system is not short-circuited as a result of copper layers touching each other

Silk Screen

The silkscreen is applied on the single-sided PCB circuit to serve as a platform on which part details.

manufacturer's information and other vital information are marked on the board.

You can see the part numbers, part references, test points, and symbol switch settings of the board on

the silkscreen.

Print the Design

Once the design is complete, print the design with a plotter printer. In this process, the design is printed into a film capturing all the specifications of the board.

Produce Substrate

At this stage, the substrate that forms the base foundation or main structure of the board is produced.

Once this is done, you need to cover the substrate with a conductive copper layer and pressure it in an oven. After this, etch the copper to create a very neat design of the laminate.

Remove Excess Layers

Here, unwanted copper layers are removed by passing them through a chemical solution. After this, use the optical punch machine to see if the layers are well aligned.

Drill the Board

With the aid of a computer-guided drill, drill holes in the single-sided PCB substrate. All excess coppers should be removed afterward.

Plate the Board

The board is plated with thin copper and layered with tin materials. By doing this, you protect all outward layers of the single-sided board.

Etch the Board

After plating the board, you need to etch the board to take away unwanted copper. Once this is complete, a solder mask is applied to the board to give it a green color.

After this, you cure and coat the board before applying a surface finish to the single-sided board.

Unlike single-sided PCB that has a single layer, multilayer PCB has two or more layers. Each layer of the multiple-sided PCB is mounted with circuit parts. Multiple-sided PCBs can handle huge circuit parts and are suitable for more complex circuit applications.

On a single-sided PCB, only one side of their layer is mounted with circuit parts. On the other hand, both sides of the double-sided PCB are mounted with circuit parts. While single-sided PCB is used for simple electronic applications, double-sided PCB can be used for complex electronic applications.

Below are some disadvantages of single-sided PCBs:

They have poor power distribution options

Single-sided PCBs have a complex routing

Single-sided PCB can't handle huge components

They can't accommodate several parts due to their simple design.

They have a poor routing densitySingle-sided PCBs have a small space and it offers little power due to their simple design. lt has a longer development time.

The only way to increase the speed and operating capacity of a single-sided PCB is to increase its dimensions. This in turn makes them heavy and big.

The few connections on the single-sided PCBs make them slow. They have a lower operating capacity due to their few circuit connections

Single-Sided PCBs have the following benefits:

They are used for making cheap devices in large quantities

Single-sided PCBs are used for making simple devices in large volumes.

They are used for producing simple equipment in large volumes

You can easily diagnose and repair single-sided PCB devices

You can easily order large of single-sided PCBs due to their easy manufacturing and turnover time

They are ideal for low-density designs

Single-sided PCBs have the following applications:

Camera systems, Power suppliers, Timing circuits, Printers, Radio equipment, Relays, and Led lighting. Vending machines, Packaging equipment, Stereo equipment

If you cannot find an answer to your question in our FAQ, you can always contact us and we will be with you shortly.