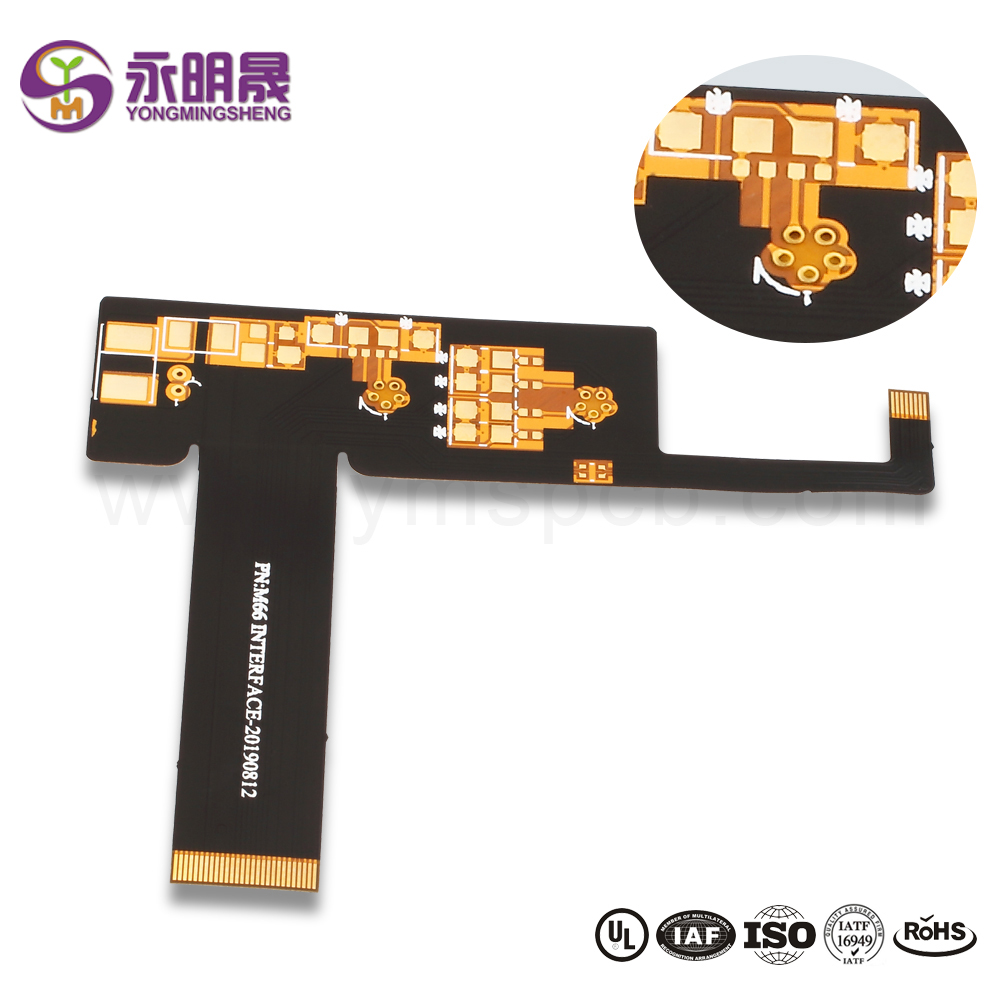

Kwamitin da'ira mai sassauƙa mai sassauƙa tana fasalta haɗakar da'irori da yawa da aka buga da kuma abubuwan da aka ajiye akan madaidaicin madauri. Waɗannan allunan da'ira kuma ana san su da allunan da'ira, masu sassauƙan PCBs , da'irori masu sassauƙa, ko da'irori masu sassauƙa. An ƙera waɗannan allunan da'ira da aka buga ta amfani da sassa iri ɗaya da ƙaƙƙarfan allunan da'ira. Duk da haka, kawai bambanci shine allon da aka yi shi ne don yin la'akari da siffar da ake so yayin aikace-aikacen.

Nau'o'in Allolin kewayawa na Flex

Za a iya ƙirƙira allunan kewayawa masu sassauƙa a cikin kewayon jeri da ƙayyadaddun bayanai. Duk da haka, an rarraba su bisa ga yadudduka da kuma daidaitawa.

Rarraba allon madaukai masu sassauƙa Dangane da Kanfigareshan

Ana rarraba allunan kewayawa masu sassauƙa cikin waɗannan nau'ikan bisa tsarin tsarin su

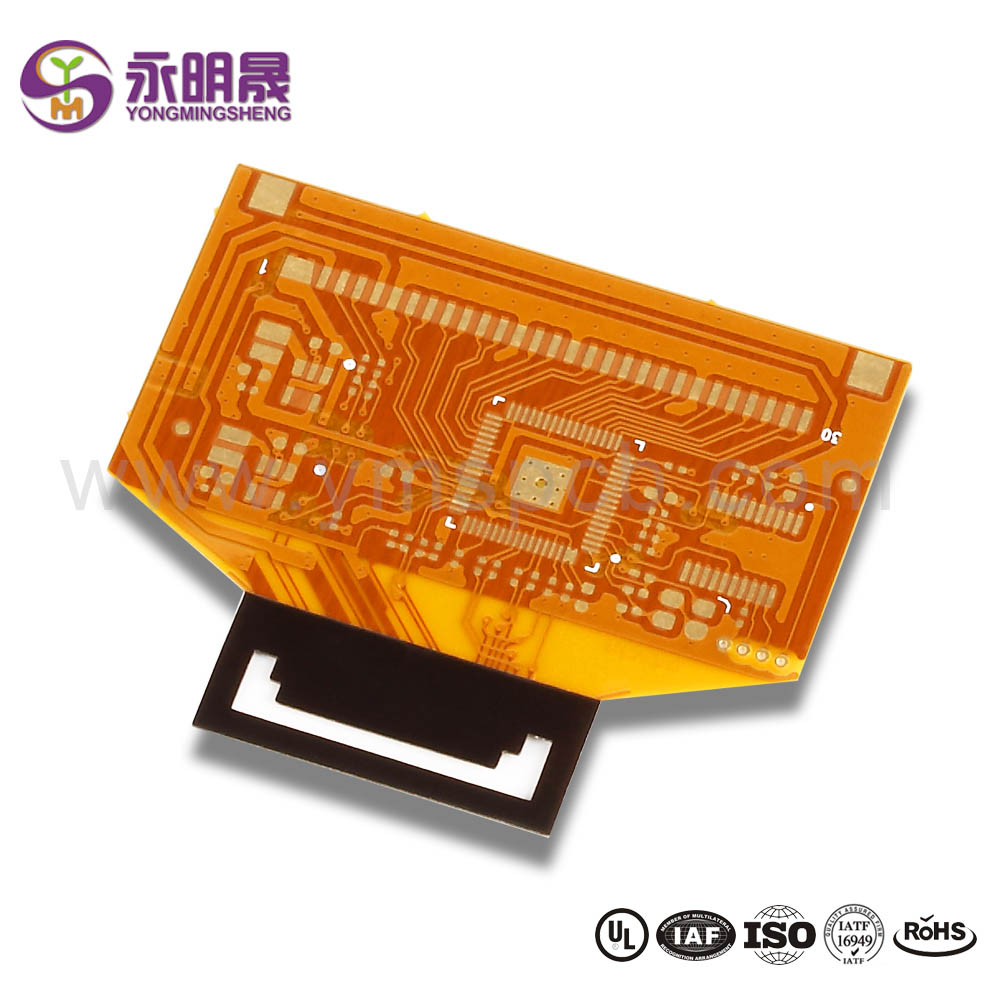

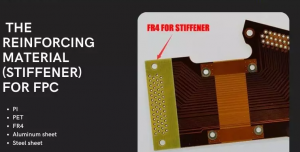

PCBs masu ƙarfi-Flex: Kamar yadda sunan ke nunawa, waɗannan PCBs ƙwararrun PCBs ne na sassauƙa da tsayayyen PCBs, kuma suna haɗa mafi kyawun tsarin duka biyun. Yawanci, ƙayyadaddun tsarin PCB mai tsauri yana fasalta jerin tsattsauran ra'ayi waɗanda aka haɗa tare ta amfani da da'irori masu sassauƙa. Waɗannan da'irori masu haɗaka suna cikin buƙata saboda suna ba da damar masu ƙira don haɓaka ƙarfin da'irorinsu. A cikin waɗannan da'irori, an fi amfani da wuraren tsattsauran ra'ayi don hawan haɗe-haɗe, chassis, da sauran abubuwa da yawa. Koyaya, wurare masu sassauƙa suna tabbatar da juriya mara girgiza, kuma suna da sassauƙa. Don haka, fa'idodi daban-daban da waɗannan allunan da'ira ke bayarwa ana amfani da su ta PCB masu zanen kaya don samar da allunan da'ira don ƙalubale aikace-aikace.

HDI PCBs masu sassauƙa: HDI taƙaitaccen bayani ne don haɗin haɗin kai mai yawa. Waɗannan PCBs cikakke ne don aikace-aikacen da ke buƙatar aiki mafi girma fiye da PCBs masu sassauƙa na yau da kullun. An ƙera allunan da'ira masu sassaucin ra'ayi na HDI waɗanda ke haɗa abubuwa da yawa kamar micro-vias kuma suna ba da mafi kyawun shimfidawa, gini, da ƙira. HDI masu sassaucin ra'ayi na PCB suna amfani da ɓangarorin ɓarke da yawa fiye da PCB masu sassauƙa na yau da kullun, wanda ke taimakawa rage girman fakitin su kuma yana haɓaka aikin wutar lantarki.

Rarraba Allolin Da'awa Mai Sauƙi Bisa Layi

An karkasa allunan kewayawa zuwa nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan iri ne masu zuwa.

· Allolin da'ira mai sassauƙa mai gefe guda: Wannan ɗaya ne daga cikin ainihin nau'ikan alluna masu sassauƙa waɗanda suka ƙunshi nau'in fim ɗin polyimide mai sassauƙa guda ɗaya tare da bakin ƙarfe na ƙarfe. Za a iya samun dama ga Layer na jan ƙarfe daga gefe ɗaya kawai na kewaye.

· Allolin da'ira masu sassaucin ra'ayi guda ɗaya tare da isa ga Dual: Kamar yadda sunan ke nunawa, waɗannan da'irori masu sassaucin ra'ayi na gefe ɗaya ne, duk da haka, takardar tagulla ko kayan jagoran ana iya samun dama daga bangarorin biyu.

· Allolin da'ira masu sassauƙa masu gefe biyu: Waɗannan allunan da'ira suna nuna nau'ikan madugu biyu a kowane gefen Layer polyimide tushe. Haɗin wutar lantarki tsakanin yadudduka masu gudanarwa ana yin su ta amfani da farantin ƙarfe ta ramuka.

· Wuraren da’ira masu sassauƙa da yawa: Al’adar da’ira mai sassauƙa mai nau’i-nau’i haɗin gwiwa ne na da’irori masu sassauƙa masu sassauƙa masu gefe biyu da guda ɗaya. Waɗannan da'irori suna haɗe-haɗe ta hanyar faranti-ta ramuka ko saman da aka ɗora cikin tsarin haɗin kai.

Fa'idodin Al'amuran da'ira Mai Sauƙi

Tsawon shekaru, allunan da'ira masu sassauƙan bugu sun sami shahara sosai saboda fa'idodin da suke bayarwa. Ga wasu fa'idodi da aka jera:

Rage Girman Girman Maɗaukaki da Fakiti: Madaidaicin allon kewayawa na iya dacewa da aikace-aikacen inda babu wasu hanyoyin da za su iya aiki. Allolin kewayawa suna da bakin ciki, masu nauyi, kuma ana iya sassauƙa su cikin sauƙi, naɗewa, da kuma sanya su a cikin wuraren, inda sauran abubuwan da ba za su iya shiga ba. A Rigiflex, injiniyoyinmu sukan yi amfani da fa'idodin marufi na 3D don tabbatar da ƙarin rage girman fakitin. .

Ingantattun Zane-zane: Ana ƙirƙira allunan da'ira masu sassauƙa da kuma haɗa su ta amfani da injina masu sarrafa kansu. Wannan yana taimakawa wajen rage kurakuran da ke cikin wayoyin da aka gina da hannu, da kuma tabbatar da daidaito, wanda shine babban abin da ake buƙata don ci-gaba na na'urorin lantarki.

’Yancin Ƙirar Ƙira: Ƙirar alluna masu sassauƙa ba ta iyakance ga yadudduka biyu kawai ba. Wannan yana ba da 'yancin ƙira da yawa ga masu zanen kaya. Ana iya yin PCBs masu sassauƙa cikin sauƙi azaman gefe ɗaya tare da hanya ɗaya, gefe ɗaya tare da samun dama biyu, da multilayered - haɗa nau'ikan da'irori masu ƙarfi da sassauƙa. Wannan sassauci ya sa ya zama cikakkiyar zaɓi don haɗaɗɗiyar jeri tare da haɗin kai da yawa. Za a iya tsara allunan kewayawa masu sassauƙa don ɗaukar duka biyun - waɗanda aka ɗora ta cikin rami da abubuwan da aka ɗora saman saman.

Babban Saitunan Maɗaukakin Maɗaukaki Mai yuwuwa: Allon da'ira mai sassauƙa na iya haɗawa da haɗaɗɗun abubuwan da aka ɗora ta cikin rami da saman da aka ɗora. Wannan haɗin yana taimakawa wajen ɗaukar manyan na'urori masu yawa tare da kunkuntar rabuwa tsakanin. Don haka, ana iya ƙirƙira masu ɗorawa masu yawa da masu sauƙi, kuma ana iya 'yantar da sarari don ƙarin abubuwan haɗin gwiwa.

· Sassautu: madaukai masu sassauƙa na iya haɗawa da jirage da yawa yayin aiwatar da aiwatarwa. Wannan yana taimakawa rage nauyi da al'amuran sararin samaniya da tsayayyen allon kewayawa ke fuskanta. Za'a iya sauƙaƙe allunan kewayawa masu sauƙi zuwa matakai daban-daban yayin shigarwa ba tare da tsoron gazawa ba.

Babban zafi mai zafi: Saboda ƙaƙƙarfan ƙira da yawan yawan na'urori, an ƙirƙiri gajerun hanyoyin zafi. Wannan yana taimakawa wajen watsar da zafi da sauri fiye da da'ira mai tsauri. Hakanan, da'irori masu sassauƙa suna watsar da zafi daga bangarorin biyu.

· Ingantaccen Jirgin Sama: Ƙaƙwalwar ƙira na sassauƙa masu sassauƙa suna ba da damar haɓakar zafi mafi kyau kuma yana haɓaka kwararar iska. Wannan yana taimakawa da'irar sanyaya fiye da takwarorinsu na hukumar da'ira. Ingantacciyar iskar iska kuma tana ba da gudummawa ga dogon aiki na allunan kewayawa na lantarki.

Dorewa da Aiyuka na Tsawon Lokaci: An ƙera allon kewayawa mai sassauƙa don daidaitawa har sau miliyan 500 a matsakaicin tsawon rayuwar na'urar lantarki. Yawancin PCBs na iya tanƙwara har zuwa digiri 360. Ƙananan ductility da taro na waɗannan allunan da'ira suna taimaka musu jure tasirin rawar jiki da girgiza, don haka inganta aikin su a cikin irin waɗannan aikace-aikacen.

Babban Amincewar Tsari: Haɗin kai ɗaya ne daga cikin manyan abubuwan da ke damun al'amuran da'ira na farko. Rashin haɗin haɗin gwiwa yana ɗaya daga cikin manyan dalilan da suka haifar da gazawar hukumar da'ira. A zamanin yau, yana yiwuwa a ƙirƙira PCBs tare da ƙananan wuraren haɗin gwiwa. Wannan ya taimaka inganta amincin su a cikin yanayi masu wahala. Bugu da ƙari, yin amfani da kayan polyimide yana taimakawa inganta yanayin zafi na waɗannan allunan kewaye.

· Ƙirƙirar Ƙirƙirar Ƙirar Ƙirar Ƙirar Ƙirar Ƙirar Ƙirar Ƙirƙirar Ƙirƙirar Ƙirƙirar Ƙirƙirar Ƙwararrun Ƙwararrun Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙadda ) ne na Ƙarfafawa sun taimaka. Abubuwan da aka gyara za a iya sauƙin hawa saman allunan, don haka sauƙaƙe ƙirar gabaɗaya.

Ya dace da aikace-aikacen zafin jiki: Kayan aiki irin su polyimide na iya jure yanayin zafi cikin sauƙi, tare da ba da juriya ga kayan kamar acid, mai, da gas. Don haka, allunan da'ira masu sassauƙa za a iya fallasa su zuwa yanayin zafi har zuwa digiri 400, kuma suna iya jure yanayin aiki mai tsauri.

Yana goyan bayan Kayayyaki Daban-daban da Masu Haɗuwa: Matsalolin Flex na iya tallafawa nau'ikan masu haɗawa da abubuwan haɗin gwiwa, gami da crimped lambobi, masu haɗin ZIF, siyarwar kai tsaye, da ƙari.

· Tattaunawar Kuɗi: Fina-finan polyimide masu sassauƙa da bakin ciki na iya dacewa da sauƙi cikin ƙaramin yanki, don haka suna taimakawa rage ƙimar taro gabaɗaya. Hakanan allunan da'ira masu sassauƙa suna taimakawa rage lokacin gwaji, kurakurai ta hanyar waya, ƙi, da lokacin sake aiki.

Kayayyakin da Ake Amfani da su don Ƙirƙirar Allolin da'ira Mai Sauƙi

Copper shine mafi yawan kayan madugu da ake amfani da su don yin PCBs masu sassauƙa. Kaurinsu na iya zuwa daga .0007ʺ zuwa 0.0028ʺ. A Rigiflex, za mu iya ƙirƙirar allo tare da madubai kamar aluminum, Electrodeposited (ED) jan karfe, Rolled Annealed (RA) jan karfe, Constantan, Inconel, tawada na azurfa, da ƙari.

Aikace-aikace na Flex Circuit Boards

Sassaukan kewayawa suna da aikace-aikace iri-iri a fagage daban-daban. Da kyar akwai wuraren lantarki na zamani da commination inda ba za ku sami amfani da PCB mai sassauƙa ba ko sabunta PCBs masu sassaucin ra'ayi.

An haɓaka da'irori masu sassauƙa don samar da aminci, ajiyar kuɗi, da kuma wasan kwaikwayo na dogon lokaci a cikin abubuwan da aka shigar. Don haka, kwanakin nan yawancin masana'antun lantarki sun zaɓi PCB masu sassauƙan da'irori don ba da dorewa ga samfuran su.

Ana amfani da waɗannan ko'ina a cikin talabijin na LCD, wayoyin hannu, eriya, kwamfyutoci, da abin da ba! Waɗannan na'urorin sadarwa sun ga haɓaka haɓakawa tare da bullar PCBs masu sassauƙa. Koyaya, amfanin da'irori masu sassauƙa ba su iyakance a nan kawai ba.

Hakanan zaka iya ganin sa a cikin na'urorin ji, tauraron dan adam na zamani, na'urorin bugawa, kamara, har ma a cikin na'urori masu ƙira. Don haka, zaku iya lura da yadda ake amfani da da'ira mai ban mamaki a zahiri a kowane fanni na wannan zamani.

ƙarshe

Wannan shi ne duk game da abin da ke m PCB da aikace-aikace da iri. Muna fatan yanzu kuna da zurfin tunani game da da'ira mai ban mamaki. Kuna iya amfani da shi a zahiri don kowane aikace-aikace a kowane fanni, kuma abin da ya sa ya shahara tsakanin kowane nau'in PCB.

Tun da zamani lantarki da sadarwa duniya dogara sosai a kan shi, YMS PCB mayar da hankali a kan masana'antu da kuma samar da mafi inganci da farashi-tasiri, m PCBs ga masana'antun.

Ƙara koyo game da samfuran YMS

Mutane kuma suna tambaya

Lokacin aikawa: Mayu-18-2022