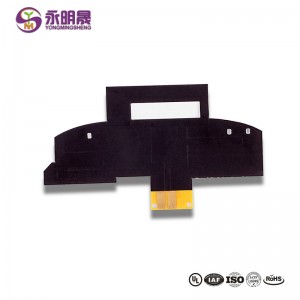

Flexible PCB Substrate 0.10mm Ultrathin 2Layer | YMS PCB

Most of the manufacturing steps of FPCs and rigid PCBs are similar. But FPCs need some tools to hold them in a fixed position because of its flexibility.

FPC's binne lichter dan stive PCB's en kinne wurde ûntwurpen foar lytsere maten foar syn fleksibiliteit. Dizze foardielen meitsje FPC's beskikber om bulk circuits te ferfangen yn guon applikaasjes. Bygelyks, FPCs kinne brûkt wurde yn Satelliten, dêr't it gewicht en folume binne de wichtichste beheinings foar ûntwerpers. Wat mear is, LED-strips, konsuminteelektronika, auto's, en in protte oare applikaasjes mei hege tichtheid favorisearje fleksibele boerden om de grutte en gewicht te ferminderjen.

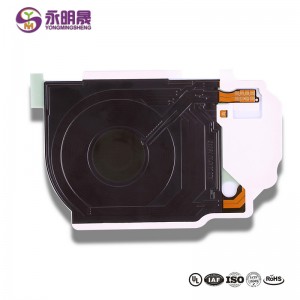

There are no mechanical connectors in FPC applications, which improves the durability in harsh environments. And the heat dissipation ability of FPCs is better than rigid PCBs. Therefore, flexible PCBs can be found in many computer components, televisions, printers, and gaming systems.

We are a professional flex PCB & rigid-flex PCB fabrikant with guaranteed quality and fast lead-time, cooperating with worldwide customers for more than ten years in China. Please send your Gerber files to get an instant quote.

SENSOR hat in protte foardielen, wêrûnder:

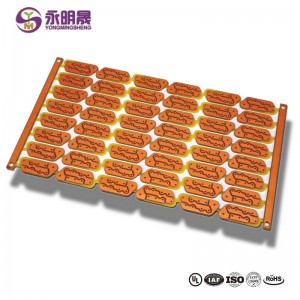

• save space. Flexible PCB designs require only about 10% of the space and weight of ordinary circuit board components, providing greater freedom of installation and packaging.The inherent flexibility also allows for more compact bending capabilities.

• enhancements. Flexible printed circuit boards are compatible with almost any type of connector or component and can be used with options such as ZIP connectors.They also perform well at extreme temperatures and have excellent radiation and chemical resistance.

• highest reliability. Flexible printed circuit boards require fewer interconnections, which in turn require fewer contact presses, connectors, and solder joints.In short, flexible PCB boards do not contain many potential fault sources, thus increasing their reliability.

• cost savings. The cost savings of flexible PCB include reduced material and packaging requirements, lower component replacement costs and assembly errors that may require maintenance.

Jo kinne leuk fine:

1. FPC (flexible circuit board) broken two major reasons analysis

3. FPC flexible circuit board can not ignore the impact of finger print

Learje mear oer YMS -produkten

What material is flexible PCB?

The dielectric layers in FPCs are typically homologous sheets of flexible polyimide material

What is flexible PCB?

Flex pcb and rigid pcb have different design and material

Hoe kin ik myn PCB fleksibel meitsje?

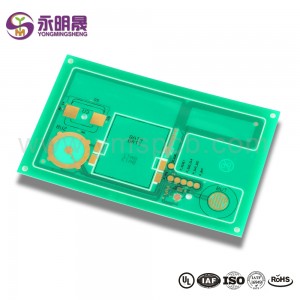

The substrate is the basic material for the manufacture of PCB.Generally,the substrate is a copper clad laminate.Single and double-sided printed boards are manufactured on the substrate material-Copper Clad Laminate(CCL).Selectively perform hole processing,electroless copper plating,copper electroplating,etching and other processing to obtain the desired circuit pattern

What is a flex PCB?

Flexible PCBs (FPC) are the PCBs that can be bent or twisted without damaging the circuits, which means the boards can be bent freely to conform to the desired shape during applications. The material the substrate used is flexible, such as Polyamide, PEEK, or a conductive polyester film.