FPC: isn't it common to say that Flexible Printed Circuit means Flexible and Printed Circuit board? It is a conductor circuit pattern made by light imaging pattern transfer and etching process method on a flexible substrate surface. The surface and inner layer of double-layer and multi-layer circuit board are electrically connected through metallized holes. The circuit graph surface is protected and insulated by PI and rubber layer.

It is mainly divided into single panel, hollow board, double panel, multilayer board and hard and soft combination board.

Flexible circuit board features

(1) short: short assembly time, complete configuration of all lines, eliminating unnecessary wiring;

(2) small: the volume is smaller than PCB (hard board), which can effectively reduce the volume of products and increase the convenience of carrying;

(3) light: lighter than PCB (hard board), which can reduce the weight of the final product;

(4) thin: the thickness is thinner than PCB (hard board), which can improve the softness and strengthen the assembly in a limited space for three dimensions.

Advantages of flexible circuit boards

Flexible printed circuit board is a printed circuit made of flexible insulating substrate, which has many advantages that rigid printed circuit board does not have:

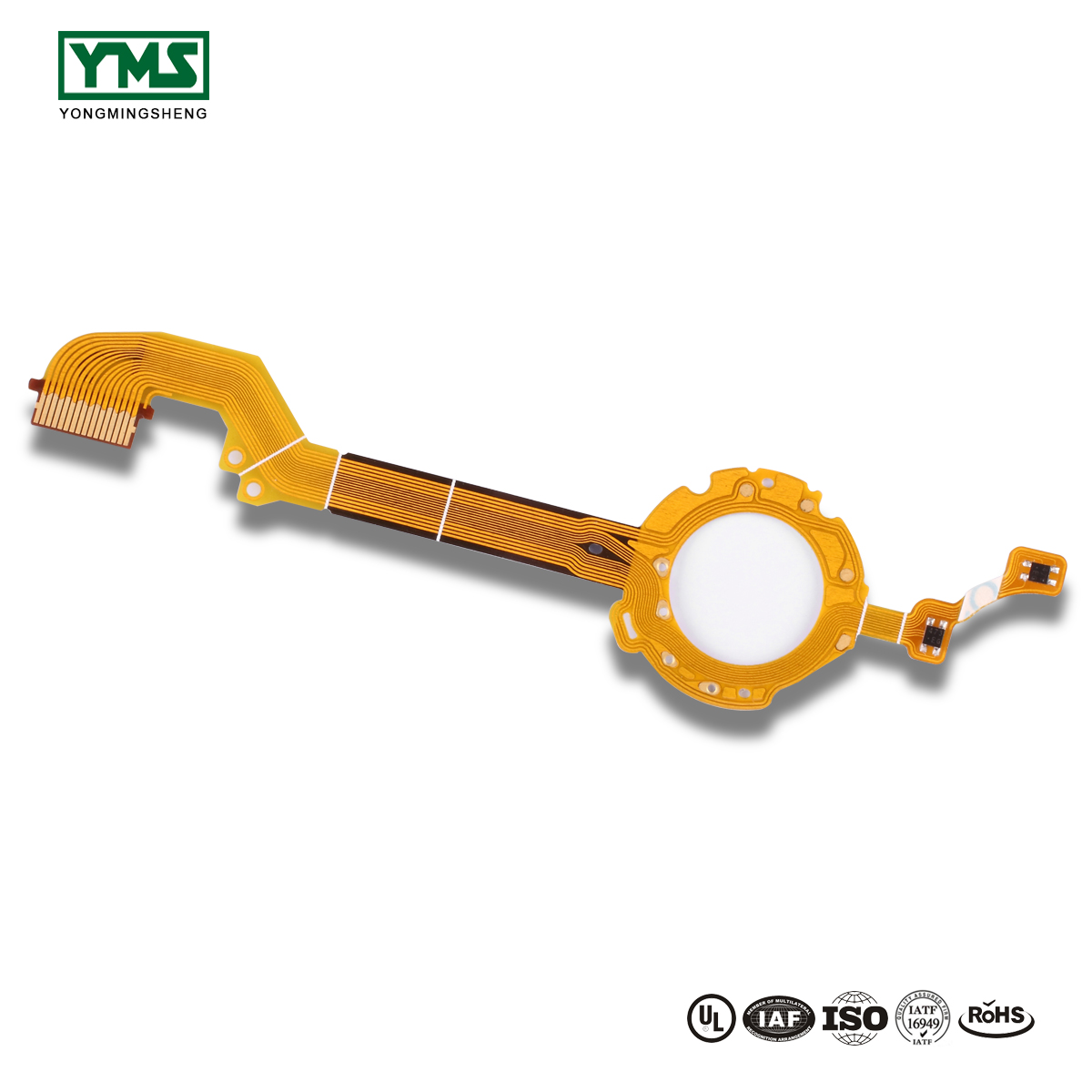

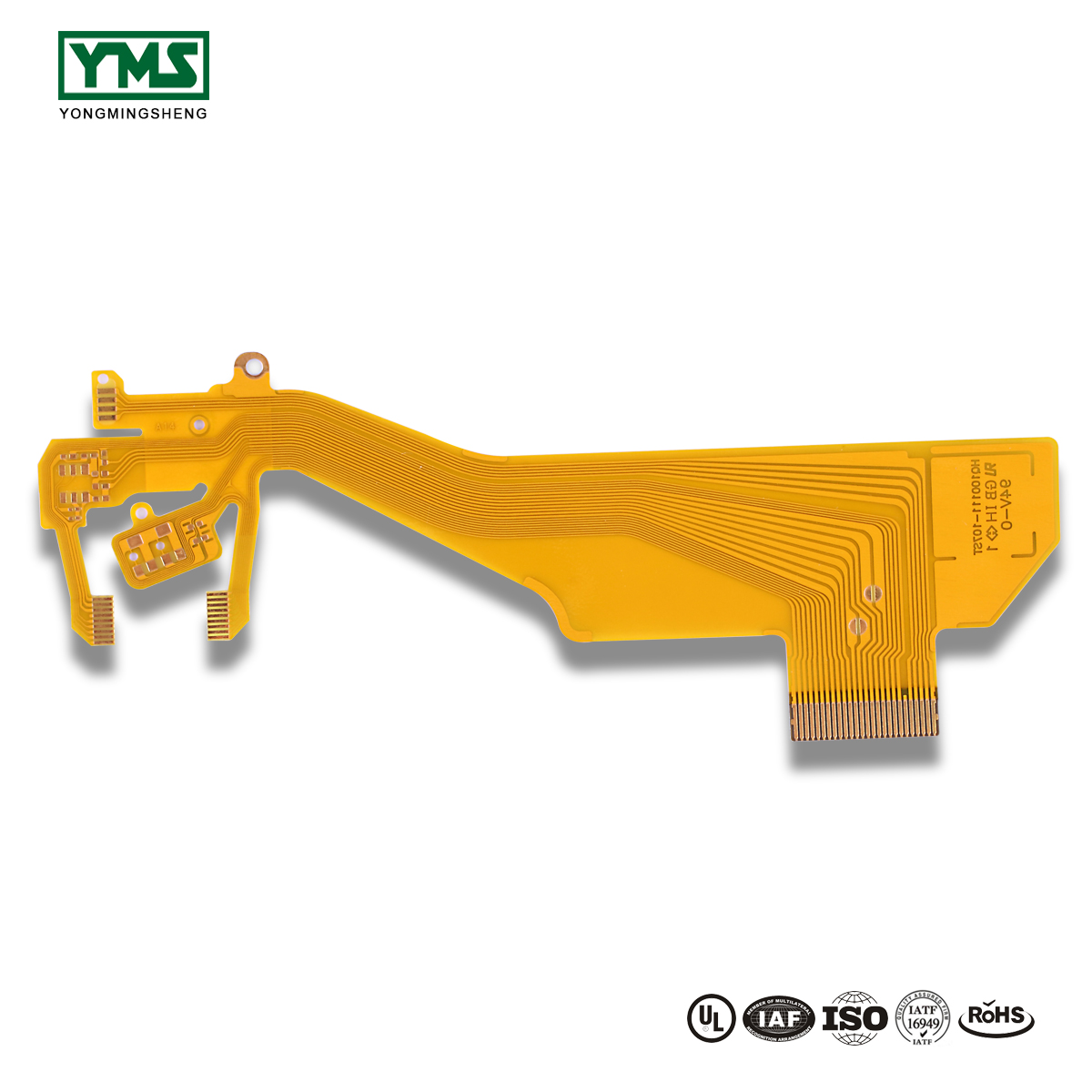

(1) Free to bend, wind and fold, and it can be arranged arbitrarily according to the requirements of spatial layout, and move and expand in three-dimensional space arbitrarily, so as to achieve the integration of components assembly and wire connection

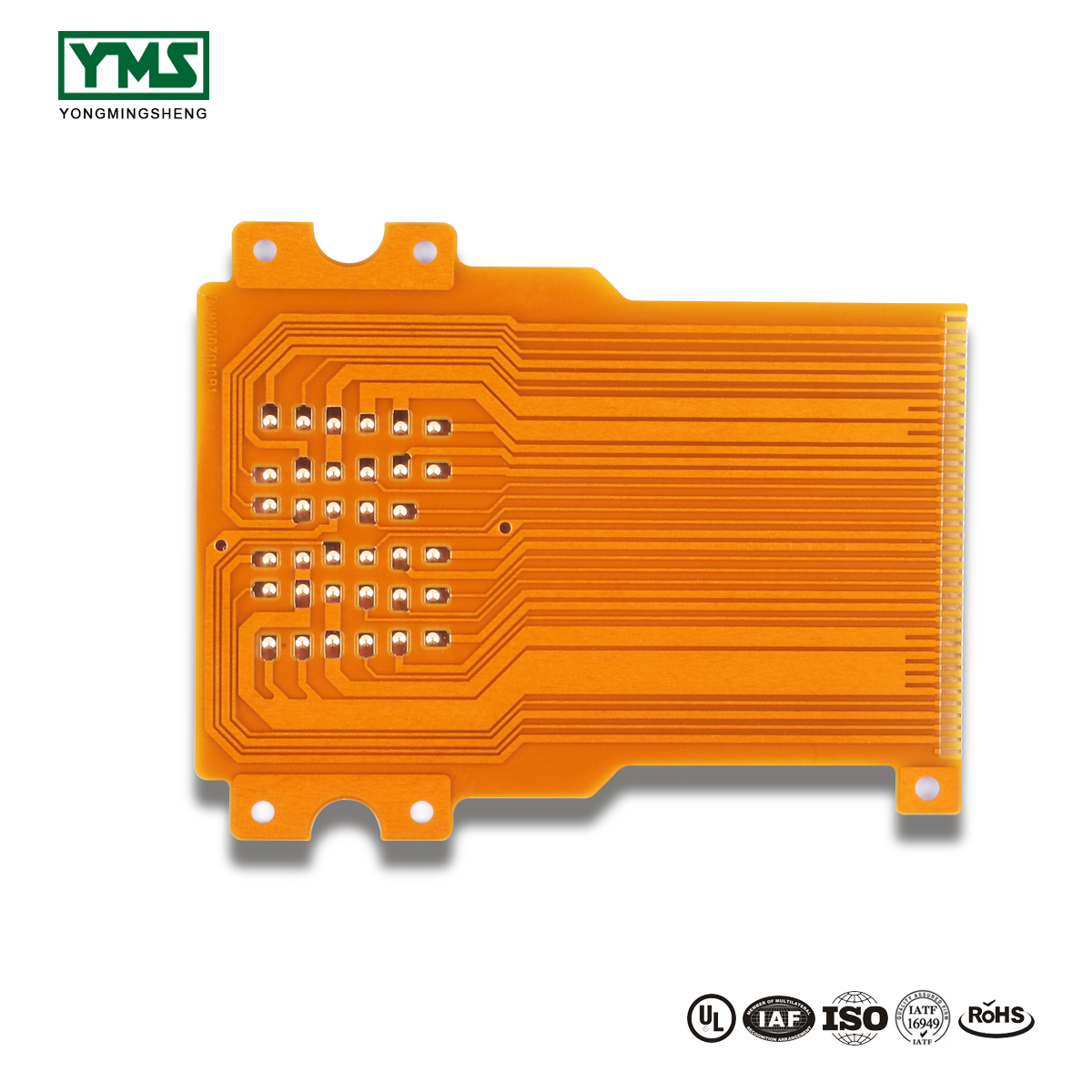

(2) FPC can greatly reduce the size and weight of electronic products, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability.Therefore, FPC has been widely used in aerospace, military, mobile communications, laptop computers, computer peripherals, PDA, digital camera and other fields or products.

(3) FPC also has the advantages of good heat dissipation and weldability, easy assembly and low comprehensive cost. The design of soft and hard combination also makes up for the slight deficiency of flexible substrate in the bearing capacity of components to some extent.

Disadvantages of flexible circuit boards

(1) high one-time initial cost: since flexible PCB is designed and manufactured for special applications, the initial cost of circuit design, wiring and photographic substrate is relatively high.Unless there is a special need to apply soft PCB, usually a small number of applications, it is best not to use;

(2) it is difficult to change and repair the soft PCB: once the flexible PCB is made, the change must start from the base drawing or the light drawing program, so it is not easy to change.Its surface is covered with a protective film, which should be removed before repair and restored after repair, which is a difficult job.

(3) size limitation: soft PCB is usually manufactured by batch process when it is not widely used, so it is limited by the size of production equipment and cannot be made very long or wide.

(4) improper operation is easy to damage: improper operation of assembly personnel is easy to cause damage of soft circuit, and its tin welding and rework need trained personnel to operate.

FPC main raw material

Its main raw materials right: 1. base material, 2. covering film, 3. stiffener, 4. other auxiliary materials.

Base material

1.1 adhesive substrate

There are three main components of adhesive substrate: copper foil, adhesive, and PI. There are two categories of single-sided substrate and double-sided substrate. The material with only one copper foil is single-sided substrate, and the material with two copper foils is double-sided substrate.

1.2 non-adhesive substrate

Without glue of base material is a no sub base material, it is compared with the ordinary rubber base material, the less the middle of the sub, only copper foil and PI in two parts, is better than have a rubber base material with thinner, the size stability, higher heat resistance, higher resistance to bending, better chemical resistance and other advantages, is widely used now.

Copper foil: at present, the commonly used thickness of copper foil has the following specifications: 1OZ, 1/2oz, 1/3oz. Now, the thinner copper foil with the thickness of 1/4 oz is introduced. However, at present, this material is already used in China to make ultra-fine lines (line width and line spacing of 0.05mm and below).With the increasing requirements of customers, materials of this specification will be widely used in the future.

Covering film

There are mainly three parts: release paper, glue, and PI, which are finally retained on the product with only glue, glue and PI. Release paper will be removed in the production process and will not be used again (its function is to protect foreign matters on glue).

stiffener

For FPC specific use of materials, in a specific part of the product to increase the strength of support, make up for FPC's "soft" characteristics.

Currently, commonly used reinforcing materials are as follows:

(1) FR4 reinforcement: the main components are glass fiber cloth and epoxy resin adhesive, the same as FR4 used in PCB;

(2) steel sheet reinforcement: it is composed of steel with strong hardness and supporting strength;

(3) PI reinforcement: the same as the covering film, it is composed of PI and rubber release paper, but its PI layer is thicker, which can be produced from 2MIL to 9MIL.

Other auxiliary material

(1) pure adhesive: this adhesive film is a kind of thermosetting acrylic ester adhesive film, which is composed of protective paper/release film and a layer of adhesive, mainly used for lamination board, soft and hard bonding board, and fr-4 / steel sheet reinforcing board to play an adhesive role.

(2) electromagnetic protection film: paste on the board to play a shielding role.

(3) pure copper foil: only copper foil composition, mainly used for hollow plate production.

The type of FPC

There are six types of FPC:

A. Single-layer board: only one side has the circuit.

B. Double-layer board: there are lines on both sides.

C. Hollow board: also known as window plate (window opening on finger side).

D. Layering board: two sides of circuit (separate).

E. Multi-layer board: more than two layers of lines.

F. Flex-Rigid board: products combining soft board and hard board.

Yongmingsheng is a China PCB manufacturer. Our products include:single layer FPC,double layer FPC,semi flex FPC.

You May Like:

Post time: Aug-21-2019