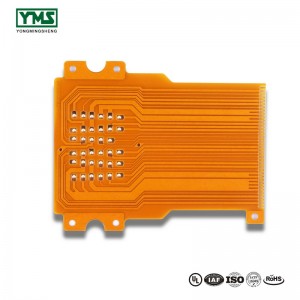

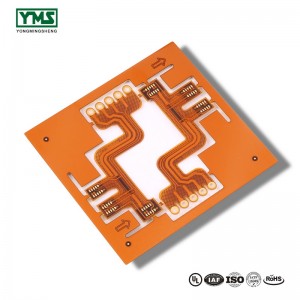

FPC connector is used to connect LCD display screen to drive circuit, mainly used in various digital communication products, portable electronic products, computer peripheral equipment, measuring instruments, automotive electronics and other fields, and it has become an indispensable electronic and digital parts.

However, the performance of FPC connectors is often affected by many factors.

1. FPC connector will accelerate the corrosion of internal metal components in a humid environment, resulting in the surface needle core being affected by moisture, and the plastic film will be slowly affected by its corrosion.

2. FPC connector will accelerate the corrosion of needle core and form the surface oxidation under the working environment with too high temperature, which may cause the connector to burn down.

3. The FPC connector is used in a high temperature and corrosive environment. The pores of the connector will cause corrosion, and the inner pin edge will be deformed at the same time.

4. In the daily use of FPC connector, please pay attention to the unnecessary use of connector, do not go to plug connector, so as not to cause internal needle core wear, thereby reducing the service life of connector.

Yongmingsheng technology co., LTD. is a manufacturer specializing in FPC and the design and production of Flex-Rigid board, committed to the production and manufacturing of FPC , to provide customers with the most competitive FPC products.

You May Like

Post time: Aug-27-2019