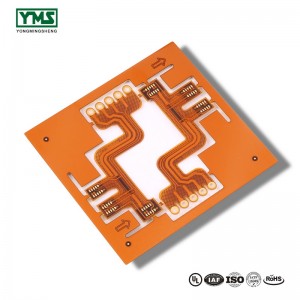

In the field of power battery application, FPC flexible circuit board is mainly used to replace the traditional wiring harness in Pack, to assist the information collection of battery Pack.

Compared with the traditional power battery wiring harness, FPC flexible circuit board has significant advantages in safety, battery pack lightweight, process flexibility and automatic production. Despite its superior performance, FPC flexible circuit board was not widely used in power batteries at the beginning of its introduction.

FPC product introduction was not as expected, mainly due to the customer’s cost and reliability concerns. As for FPC material alone, in the case of small batch use, its use cost is significantly higher than that of traditional wire harness.

As a new application, battery and Pack manufacturers were initially skeptical about the FPC’s performance.

Before the introduction of FPC flexible circuit board, battery manufacturers will conduct a long period of testing of FPC products in the early stage, which requires in-depth cooperation of both sides, and also puts forward higher requirements for supplier r&d support, manufacturing process, etc., which is the difficulty for only a few enterprises to realize batch application at present.

On the one hand, the power battery has put forward the requirements of temperature and pressure resistance for FPC, so the FPC products must be high-quality and durable;

On the other hand, due to the battery voltage, temperature, current, and so on and so forth for timely and accurate control, power battery according to specific needs with FPC assembly performance and shape for customized production, supplemented by a complex process of adjustment, as well as the strict test process, procedure, appear flaw, the whole piece of FPC will be invalid.

As a vehicle component, power battery has put forward very strict requirements on the durability, stability and reliability of FPC, and the relatively high threshold has delayed the introduction of FPC into a large area to some extent.

In order to balance the cost factor, FPC manufacturers have developed the “FPC+ traditional wiring harness” collocation mode based on the actual situation of some power battery factories. The use effect after compromise is also significant, which plays a positive role in improving the performance of power battery such as space utilization, lightweight and automation.

Although there are still some obstacles in terms of cost and reliability, the introduction environment of FPC in the power battery field has been greatly improved by the joint efforts of power battery enterprises and FPC manufacturers.

Post time: Sep-02-2019