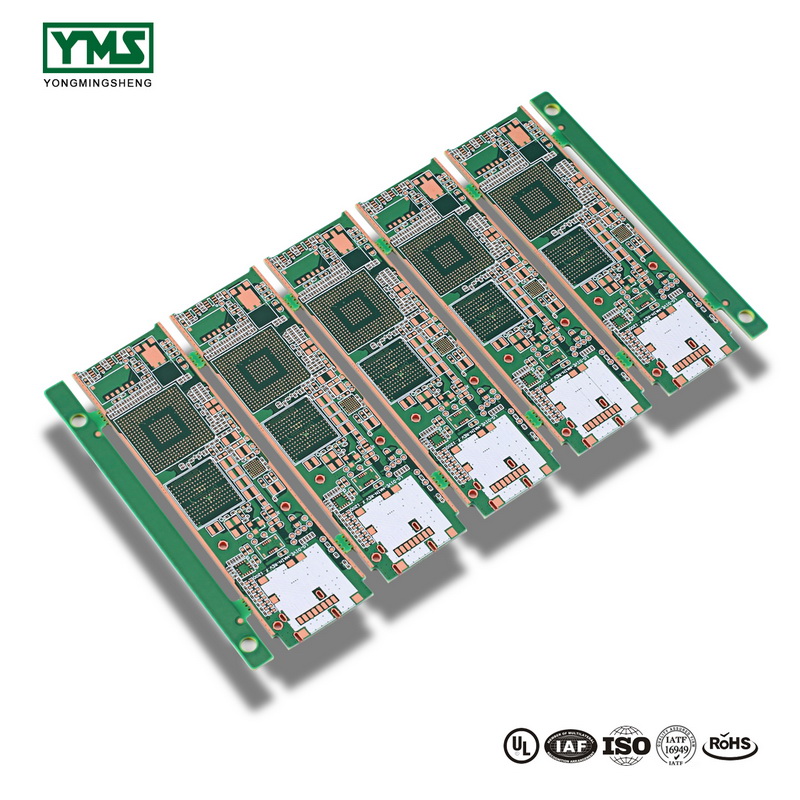

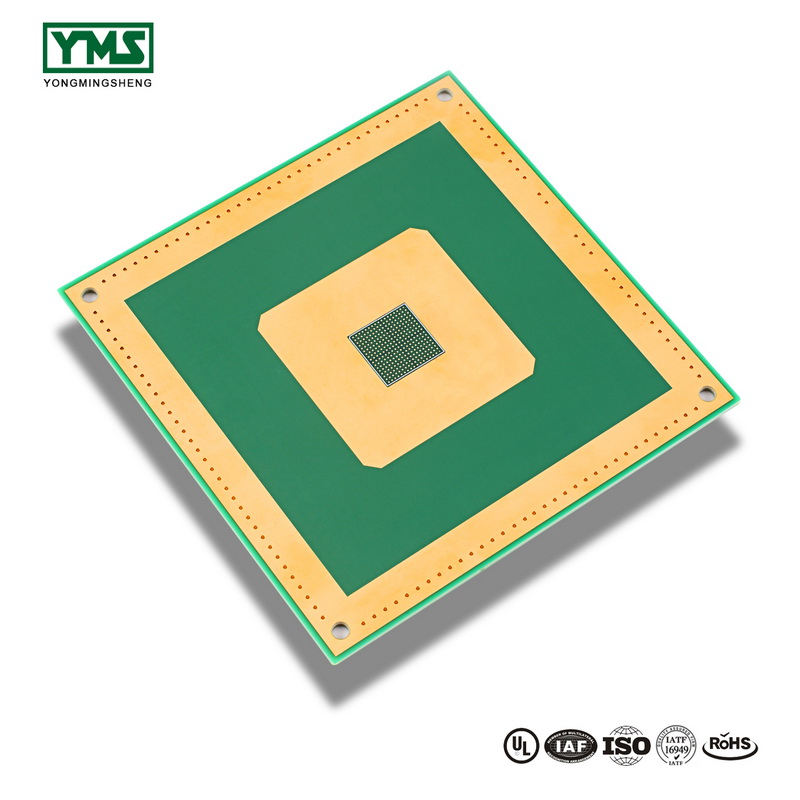

Compared with single-sided circuit board, double sided pcb board has higher wiring density and smaller aperture.Layer – to – layer interconnection depends on metallized holes, directly related to the reliability of printed circuit board.With the aperture of the small, some sundries, such as brush debris, volcanic ash, and so on, once left in the hole inside, will make the chemical sink copper, electroplating copper loss.

In order to ensure the reliable conduction effect of double-sided circuit board, the connecting hole on the board should be welded with the wire type first, and the protrusion part of the connecting wire tip should be cut off, so as not to stab the operator’s hand. This is the preparation work of the connecting line of the board.

So, what problems should be paid attention to in double sided pcb board welding?

1. For devices requiring shaping, it shall follow the requirements of the process drawing, shaping first and then the plug-in.

2. After shaping, the type of diode should face up, and the length of the two pins should not be inconsistent.

3. For devices with polarity requirements, it shall be noted that the polarity shall not be inserted into the opposite direction. No obvious tilt shall be allowed for vertical or horizontal devices after insertion.

4. The power of the electric soldering iron is 25~40W, the temperature of the electric soldering iron head should be controlled at 242℃ or so, and the welding time should be controlled at 3~4 seconds.

5, welding generally according to the device from high to high, from the inside to the outside of the welding principle to operate, welding time to master, too long time will be hot device, will also hot copper clad wire on the copper clad plate.

6, because it is double-sided welding, so should also make a process frame to place the circuit board, the purpose is not to press the device below.

7. After the completion of welding, a comprehensive inspection shall be carried out to check the places where there are leakage inserts and welds. After confirmation, trim the redundant device pins and let them flow into the next process.

8. The specific operation shall strictly follow the relevant process standards to ensure the welding quality.

The above are the precautions for double sided pcb board welding operation. If you do not know, you can consult China pcb board manufacturer — Yongmingsheng Circuit board Company at any time.

Post time: Oct-15-2020