Want to know the three point difference between fiberglass and aluminum substrate?Yongmingsheng technology aluminum pcb factory for you to explain.

What is fiberglass

Fiberglass Insulation Board (FR-4), also known as Fiberglass Insulation Board, is made of fiberglass materials and composite materials with high heat resistance. It does not contain asbestos which is harmful to human health.

The advantages of glass

Fiber board have very high mechanical properties and electrical resistance, but also have good heat and moisture resistance, as well as good workability.Generally used in plastic mold and machinery manufacturing.

Application of glass fiber board:

1. Construction industry.

2. Chemical industry.

3. Automobile and railway transportation industry.

Good insulation characteristics, so that it has been used in radar housing.It is also a good anticorrosive material and has been widely used in the chemical industry.Glass fiberboard has the advantage of strong plasticity.

What is aluminum substrate

Aluminum substrate is a kind of metal-based copper clad plate with good heat dissipation function. Generally, a single panel is composed of three layers of structure, namely the circuit layer (copper foil), the insulation layer and the metal base layer.

Advantages of aluminum substrate

The heat dissipation is significantly better than that of standard FR-4 structure.The dielectric used is usually five to ten times as conductive as conventional epoxy glass and is one-tenth as thick.Heat transfer index is more efficient than traditional rigid PCB.A lower copper weight than that shown in the IPC recommended diagram can be used.

Use of aluminum substrate

1. Audio equipment

2. Power supply equipment

3. Communication electronic equipment

4. Office automation equipment: motor driver

5. The car

6. Computer

7. Power module

Three major differences between fiberglass and aluminum substrate

1. Price

The important components of LED fluorescent lamp are: circuit board, LED chip and drive power supply.The commonly used circuit board is divided into two kinds: aluminum substrate board and glass fiber board respectively.

The price comparison between glass fiber board and aluminum substrate shows that the price of glass fiber board is obviously much cheaper, but the performance of aluminum substrate will be better than that of glass fiber board.

2. Process

Glass fiber board can be divided into double-sided copper foil fiberboard, perforated copper foil fiberboard and single-sided copper foil fiberboard according to different materials and production techniques. Of course, glass fiber board made of different materials will have different prices.Different material and technology make the glass fiber board price is not the same.The LED daylight lamp using glass fiber board is not as good as the LED daylight lamp using aluminum substrate in heat dissipation.

3. Performance

As we all know, aluminum substrate has good heat dissipation performance, and its heat dissipation performance is much better than glass fiber board, because aluminum substrate has good thermal conductivity is the aluminum substrate plays a relatively important role in the field of LED lamps and lanterns.

So those are the three differences between fiberglass and aluminum substrate.Huizhou Yongmingsheng Technology Co., Ltd. is a professional manufacturer of aluminum substrate.I hope this article can give you some knowledge of aluminum substrate.

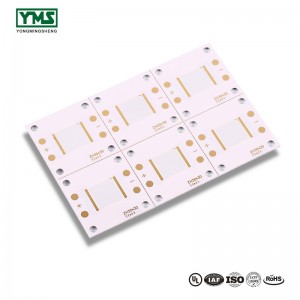

Image information aluminum pcb

Post time: Jan-14-2021