Chinese PCB manufacturer tells you

What is a printed circuit board?

Printed circuit boards (PCBS) are the boards used as substrates in most electronic devices - both as physical support and as wiring areas for surface mount and socket assemblies.PCB is usually made of glass fiber, composite epoxy resin or other composite materials.

Most PCBS for simple electronics are simple and consist of a single layer.More complex hardware, such as computer graphics CARDS or motherboards, can have multiple layers, sometimes as many as 12.

What are the types of PCB boards?

There are many types of PCB boards, each with its own unique manufacturing specifications, material types and USES: single-layer PCB, double-layer PCB, multi-layer PCB, rigid PCB, flexible PCB, rigid flexible PCB, high-frequency PCB, etc

A single layer PCB

Single - or single-sided PCB is a PCB or substrate made from a single - layer substrate.One side of the substrate is coated with a thin layer of metal.Copper is the most common coating because it conducts electricity well.Once the copper base coating is applied, a protective welding mask is usually used and all elements on the last screen are printed.

Because single-layer/single-sided PCB only weld various circuits and components on one side, it is easy to design and manufacture.This popularity means they can be bought cheaply, especially for large orders.Low-cost, high-capacity models mean they are commonly used for a variety of applications, including calculators, cameras, radios and stereo equipment, solid-state drives, printers and power supplies.

Double layer printed circuit board

The substrate material for a double - or double-sided printed circuit board has a thin layer of conductive metal, such as copper, applied to both sides of the board.Holes drilled through the circuit board allow the circuit on one side of the circuit board to be connected to the circuit on the other side.

The components of the circuit and the double-layer PCB board are usually connected in one of two ways: using a through hole or using a surface mount.A through hole connection means that small wires called leads are fed through the hole and each end of the lead is welded to the right assembly.

Surface mounted PCB cannot use wire as connector.Instead, many small leads are welded directly to the circuit board, meaning that the circuit board itself is used as the wiring surface for the different components.This allows the circuit to be completed in less space, freeing up space and allowing the circuit board to perform more functions, often faster and lighter than the through-hole board allows.

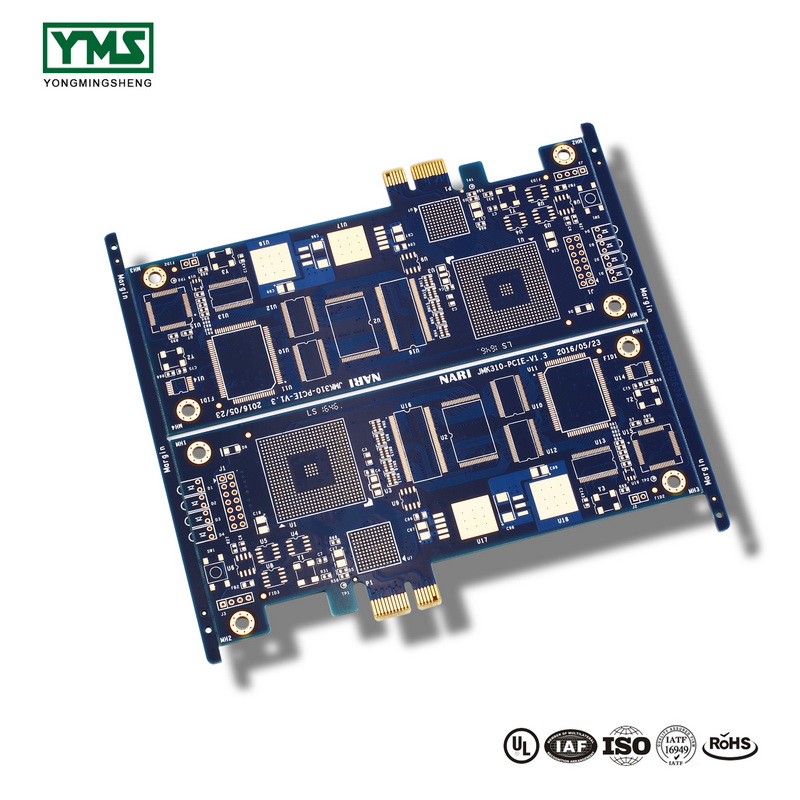

Multilayer PCB

Multilayer PCB consists of a series of three or more layers of double-layer PCB.These plates are then held together with a special adhesive and clamped between the insulation pieces to ensure that the excess heat does not melt any of the components.Multilayer PCB comes in a variety of sizes, from four to ten or twelve layers.The largest ever multilayer PCB is 50 layers thick.

For multilayer printed circuit boards, designers can make very thick, complex designs suitable for all kinds of complex electrical tasks.Beneficial applications of multilayer PCB include file servers, data storage, GPS technology, satellite systems, weather analysis and medical equipment.

Rigid PCB

A rigid printed circuit board is a printed circuit board made of a solid substrate material that prevents the circuit board from twisting.Perhaps the most common example of a rigid PCB is a computer motherboard.The motherboard is a multilayer PCB designed to distribute power from a power source while allowing communication between all parts of the computer, such as the CPU, GPU, and RAM.

Rigid PCB composition is probably the largest number of PCBS manufactured.These PCBS can be used anywhere where the PCB itself needs to be set to a shape and remain so for the rest of the device's life.The rigid PCB can be as simple as a single layer PCB, or as 8 or 10 layers PCB.

All rigid PCBS have a single, double or multilayer structure, so they share the same application.

Flexible PCB

Unlike rigid PCBS, which use nonstick materials such as fiberglass, flexible PCBS are made from materials that can be bent and moved, such as plastics.Similar to a rigid PCB, a flexible PCB comes in a single, double, or multilayer format.Because they need to be printed on flexible materials, they tend to be more expensive to manufacture.

Still, flexible PCB offers many advantages over rigid PCB.The most striking of these advantages is their flexibility.This means they can be folded around the edges and wrapped around corners.Their flexibility saves cost and weight because a single flexible PCB can be used to cover areas where multiple rigid PCB may be required.

Flexible PCB can also be used in areas that may be affected by multiple rigid PCB.Environmental hazards.For this purpose, they are made only of materials that may be waterproof, shock-resistant, corrosion-resistant or high-temperature oil-resistant - an option that traditional rigid PCBS may not have.

Flexible rigid PCB

When it comes to the two most important overall PCB boards, flexible rigid PCB combines the advantages of both.The flexible rigid board is composed of multiple layers of flexible PCB, attached to multiple rigid PCB layers.

Flexible rigid PCB has many advantages over using rigid or flexible PCB only in certain applications.For example, rigid-flexible plates have fewer parts than traditional rigid or flexible plates because the wiring options for both can be combined into a single plate.Combining rigid and flexible boards into a single rigid-flexible board also enables a more streamlined design, thereby reducing the overall circuit board size and package weight.

Flexible, rigid PCBS are most commonly found in the most space - or weight-focused applications, including mobile phones, digital cameras, pacemakers and cars.

High-frequency PCB

High-frequency PCB refers to the common PCB design elements, not the PCB structure like previous models.High-frequency PCBS are circuit boards designed to transmit signals over 1 gigahertz.

High-frequency PCB materials commonly include FR4 glass fiber reinforced epoxy laminates, polyphenylene ether (PPO) resins, and teflon.Teflon is one of the most expensive options because of its small but stable dielectric constant, small dielectric loss and overall low water absorption.

There are many aspects to consider when selecting high frequency PCB boards and their corresponding types of PCB connectors, including dielectric constant (DK), dissipation, loss, and dielectric thickness.

The most important of these is the Dk of the material in question.Materials with a high probability of permittivity change often produce impedance changes that disrupt the harmonics that make up the digital signal and result in an overall loss of digital signal integrity - a factor that high-frequency PCBS are designed to prevent.

There are many aspects to consider when selecting high frequency PCB boards and their corresponding types of PCB connectors, including dielectric constant (DK), dissipation, loss, and dielectric thickness.

The most important of these is the Dk of the material in question.Materials with a high probability of permittivity change often produce impedance changes that disrupt the harmonics that make up the digital signal and result in an overall loss of digital signal integrity - a factor that high-frequency PCBS are designed to prevent.

Other considerations when choosing the type of circuit board and PC connector to use when designing a high-frequency PCB include:

• dielectric loss (DF), which affects the quality of signal transmission.A small dielectric loss may result in a small amount of signal waste.

• thermal expansion.If the materials used to construct the PCB, such as copper foil, have different thermal expansion rates, the materials may separate from each other due to temperature changes.

• water absorption.High water intake can affect the dielectric constant and dielectric loss of PCBS, especially when used in humid environments.

• other resistors.Materials used to construct high-frequency PCBS shall be rated for resistance to heat, impact, and hazardous chemicals as required.

Aluminum backing PCB

The aluminum backing is lined with an insulating material designed with low thermal resistance, meaning less heat is transferred from the insulation to the backing.Once the insulation is applied, a layer of copper, ranging in thickness from 1 ounce to 10 inches, is applied.

Aluminum backed PCB has many advantages over fiberglass backed PCB, including:

• low cost.Aluminum is one of the most abundant metals on earth, accounting for 8.23 percent of the earth's weight.Mining aluminum is easy and cheap, which helps reduce costs in the manufacturing process.As a result, it is cheaper to make products out of aluminum.

• environmental protection.Aluminum is nontoxic and easy to recycle.Making printed circuit boards out of aluminum is also a good way to save energy due to its ease of assembly.

• heat dissipation.Aluminum is one of the best materials for heat dissipation from key parts of circuit boards.Instead of dissipating the heat to the rest of the plate, it transmits it to the open air.Aluminum PCB cools faster than copper PCB of the same size.

• material durability.Aluminum is more durable than other materials such as fiberglass or ceramics and is especially suitable for drop testing.Using stronger substrates helps reduce damage during manufacturing, transportation, and installation.

All of these advantages make aluminum PCB an excellent choice for applications requiring high output power within a very strict tolerance range, including traffic lights, automotive lighting, power supplies, motor controllers and large current circuits.

In addition to the main areas of use, aluminum-backed PCB can also be used where high mechanical stability is required or where PCB may withstand high levels of mechanical stress.They are less susceptible to thermal expansion than fiberglass wikis, meaning that other materials on the circuit board, such as copper foil and insulation, are less likely to peel off, further extending the life of the product.

You May Like

Post time: Apr-30-2020