Ama- PCB e-Ceramic asebenzisa izitsha zobumba njengezisetshenziswa zawo eziyisisekelo, futhi adinga izinga lokushisa eliphakeme kakhulu lokukhiqiza kunamanye ama-PCB. Njengezinto eziyisisekelo ze-PCB, izitsha zobumba ezisetshenziselwa ama-PCB zinenzuzo yakho kokubili i-FR4 nensimbi. Izinto ze-FR4 ziyi-insulating kagesi, kodwa ukuqhutshwa kwe-thermal kubi; i-aluminium ne-copper zinokusebenza okuhle kakhulu kwe-thermal, kodwa zingabaqhubi. Ama-Ceramic PCB ane-thermal conductivity enhle futhi awadingi isendlalelo sokufakwa kukagesi njengoba izitsha zobumba ziyizivikeli ezinhle.

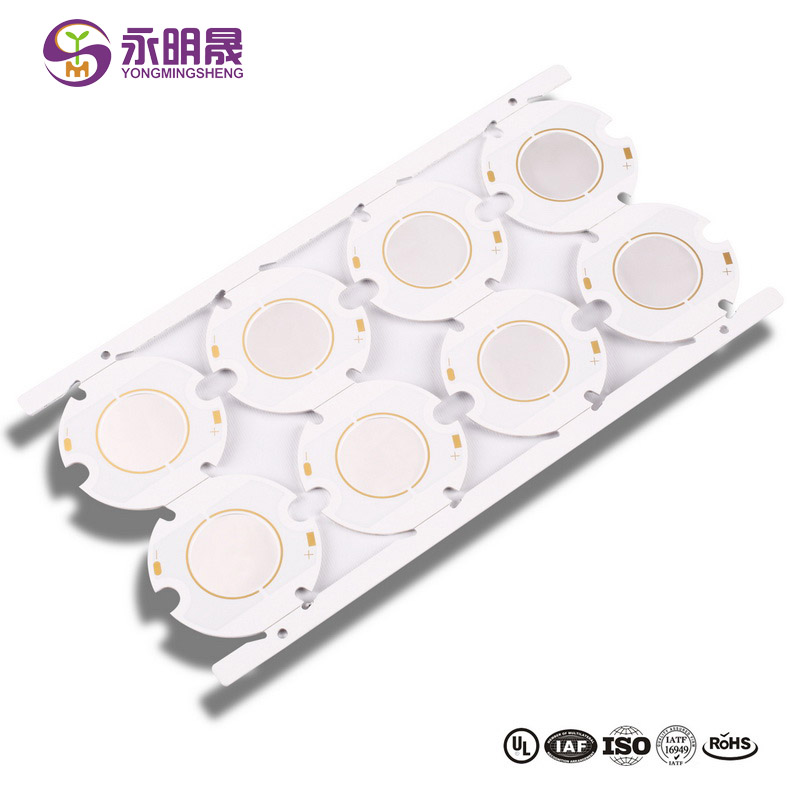

Uma ama-PCB e-ceramic efakwe ngama-chips e-LED, ama-IC, nezinye izingxenye, aba ama-PCBA e-ceramic. Ama-LED angahlanganiswa kuma-PCB e-ceramic ngokusebenzisa i-wire bonding noma indlela ye-flip-chip. Ama-Ceramic PCBAs ngokuvamile ayizingxenye eziyinhloko kuzinhlelo zokusebenza zamandla aphezulu kanye nama-high-frequency, njengezilawuli zamandla esikali semoto, amasistimu okukhanya okuguquguqukayo, iziguquli zokushintshanisa, amabhethri kagesi welanga, izibani ze-LED zamanje...

Kungani i-ceramic PCB idume kangaka?

Ukwandiswa Okushisayo Okuphezulu

Isizathu sokuqala sokuthi kungani amabhodi e-ceramic adume kakhulu emkhakheni we-electronics ukunwetshwa kwawo okuhle kakhulu kwe-thermal coefficient. Kuhle ukuqaphela ukuthi ukushisa kwesisekelo se-ceramic kucishe kufane ne-silicon futhi kungasebenza njengento yokuxhuma. Ngaphandle kwalokho, ungayisebenzisa njenge-isolator. Ngakho-ke, kukhona ukusetshenziswa okuphezulu kwezakhiwo ezishisayo zamabhodi e-ceramic, ngisho nasezimweni ezimbi.

Ukuzinza

Ukusetshenziswa kwe-ceramic kuletha umthamo ozinzile we-dielectric, futhi ungakwazi ukuguqula ibhalansi ibe ukulahlekelwa kwe-radiofrequency ingxenye ukuze ukhulise amandla edivayisi yakho. Noma kunjalo, naphezu kokuqina kobuso, izinto ze-ceramic ziza nokumelana okungokwemvelo ngokumelene nokuguguleka kwamakhemikhali. Ukumelana namakhemikhali e-Ceramic kungashintsha ukumelana noketshezi kanye nomswakama.

Ukuguquguquka

Ungakha izimo zokusebenzisa ezimbalwa ukuze uhlanganise ibhodi eliwumgogodla wensimbi ngokunwetshwa okuphezulu kokushisa. Ngaphandle kwalokho, usengakwazi ukuguqula umgogodla wensimbi ube ama-conductor athembekile usebenzisa i-sintering technique. Ngakho-ke, ukusetshenziswa kwe-ceramic PCB kunenzuzo ngenxa yamazinga okushisa aphezulu okucubungula.

Ukuqina

Inqubo yokwenziwa kwebhodi le-ceramic idala ukuqina ngokusebenzisa izakhiwo eziyingqayizivele, njengokuqina. Lokho kuvimbela i-PCB yakho ukuthi ingagugi. Ngakho ungaqiniseka ukuthi ngeke ushintshe i-PCB yakho maduze ngenxa yomthamo wayo wokuguga kancane. Futhi, ukumelana okuphezulu okushisayo kwe-ceramic PCB kuyenza icabange inqubo yokubola eyehlisiwe.

Ukuzivumelanisa nezimo

Okokugcina, ukusetshenziswa kwezinsimbi zensimbi kungasebenza njengabathwali abangaguquki abanikeza ukuqina komshini. Lesi sakhiwo sikwenza kube lula ukusebenzisa ama-PCB e-ceramic kunoma yisiphi isimo ngenxa yokumelana okuphezulu nokugqwala nokuguga okuvamile.

Izinzuzo ze-ceramic PCB

Ukukhipha ukushisa kuyinzuzo eyinhloko i-ceramic enayo ngaphezu kwezinto ezivamile ezifana ne-FR-4 ne-metal clad PCB. Ngenxa yokuthi izingxenye zibekwe ngokuqondile emabhodini, futhi asikho isendlalelo sokuhlukanisa, ukugeleza kokushisa ngamabhodi kuphumelela kakhulu. Ngaphezu kwalokho, izinto ze-ceramic zingahlushwa amazinga okushisa aphezulu okusebenza (afinyelela ku-350°C), ngaphezu kwalokho, ine-coefficient ephansi kakhulu yokwandisa okushisayo (CTE), okuvumela izinketho ezengeziwe zokuhambisana zomklamo we-PCB.

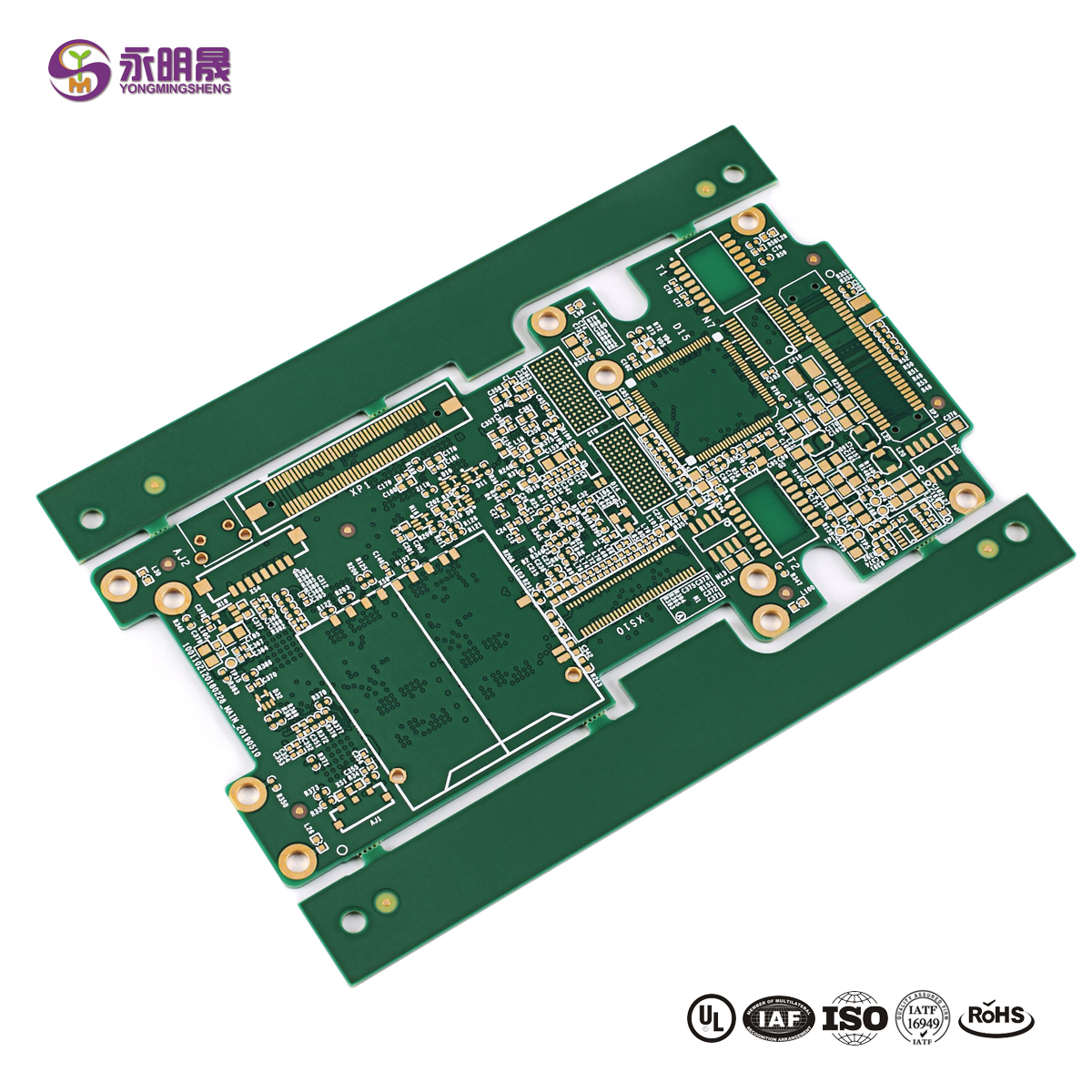

Uma kuqhathaniswa nama-PCB endabuko ama-substrate akhona okuyi-epoxy glass fiber, i-polyimide, i-polystyrene ne-phenolic resin, ama-PCB e-ceramic afaka lezi zakhiwo ezilandelayo:

Excellent conductivity thermal

Melana nokuguguleka kwamakhemikhali

Ukuqina komshini okuhambisanayo

Kwenze kube lula ukusebenzisa ukulandelela kokuminyana okuphezulu

Ukuhambisana kwengxenye ye-CTA

Iphuzu lokugcina

Ama-PCB endabuko ahlanganiswe nesisekelo se-organic substrates aqhubekela phambili aye ekumineni okuthile okungavamile, ukwethembeka okuphezulu, ukunemba okuhle, nokuqina ngokwethulwa kobuchwepheshe be-chip embonini yezogesi. Amabhodi esekethe e-Ceramic awuhlobo olusha lwe-PCB oluthola ukuvelela embonini yezogesi ngenxa yezici zabo ezihlukile.

Ama-Ceramic PCB ahlinzeka ngezinzuzo eziningi ngaphezu kwamabhodi avamile. Ama-PCB e-Ceramic aguquguquka kakhulu, awanzima kakhulu, futhi asebenza kangcono kunamabhodi esekethe avamile ngenxa yokushisa kwawo okuphezulu kanye ne-coefficient ephansi yokwandisa (CTE). Onjiniyela bakholelwa ukuthi lawa ma-PCB ayinketho engcono kakhulu yokwenza amagajethi kagesi asezingeni eliphansi. Ngethemba, uwutholile umbono mayelana nokuthi Ungayazi Kanjani I-PCB Ye-Ceramic Engcono Kakhulu futhi manje usungakwazi ukukukhethela engcono kakhulu.

Ividiyo

Funda kabanzi ngemikhiqizo ye-YMS

Isikhathi sokuthumela: Feb-25-2022