1. Choose PCB

PCB selection must be balanced between meeting design requirements and mass production and cost. Design requirements include electrical and mechanical components.

This is usually important when designing very high speed PCB (higher than GHz frequency). Now commonly used FR-4 material, for example, when several GHz frequency of dielectric loss has the great influence on the signal attenuation, may not be enough. In terms of electrical, pay attention to the dielectric constant and the frequency of dielectric loss in design is operable.

2. Avoid high-frequency interference

The basic idea of avoiding high frequency interference is to minimize interference with electromagnetic fields of high frequency signals, known as Crosstalk. You can stretch the distance between the high speed signal and the analog signal, or add ground guard/shunt traces. Also note the digital to analog noise interference.

3. Solve the signal integrity

Signal integrity is basically a matter of impedance matching. The factors that affect impedance matching include structure of signal source and output impedance, characteristic impedance of routing, characteristics of load end, topology structure of routing, etc.The solution is to rely on termination and wire routing topology.

4. Differential wiring

There are two points to note when wiring a differential pair, one is that the length of the two lines should be as long as possible, the other is that the spacing between the two lines (which is determined by the differential impedance) should remain unchanged, that is, parallel. There are two ways to be parallel: one is when two lines go side-by-side, and the other is when two lines go over-under. The former is generally implemented side-by-side.

5. For only one output of the clock signal line, how to achieve differential wiring

To use differential wiring must be the source and the receiver are also differential signals to make sense. Therefore, differential routing is not possible for clock signals with only one output.

6. The difference of the wiring should be close to and parallel

The wiring of the differential pairs should be appropriately close and parallel. The proper proximity is because it affects the differential impedance value, which is an important parameter in the design of difference pairs. Parallelism is also required to maintain the consistency of the differential impedance. If the two lines are not close or far, the differential impedance will be inconsistent, which will affect signal integrity and timing delay.

7. Can a matching resistance be added between the difference lines at the receiving end

The matching resistance between the receiving differential line pairs is normally added and its value should be equal to the value of the differential impedance.The signal quality will be better.

8. How to solve the contradiction between manual and automatic wiring of high-speed signals

Now a strong routing software automatic wiring most have set constraints to control the way of winding and the number of holes. The winding engine capabilities and constraint setting programs of EDA companies sometimes differ widely.

For example, whether there are enough constraints to control the serpentine winding way, whether the difference pair of line spacing can be controlled, etc. This will affect the way the automatic wiring works in the designer's mind.

In addition, the difficulty of manually adjusting wiring is absolutely related to the ability of the winding engine. For example, the shoving ability, the shoving ability through the hole, even the shoving ability on the copper coating and so on. Therefore, the choice of a strong winding engine cabling, is the solution.

9. How to deal with some theoretical conflicts in actual wiring

Basically, it's right to divide and isolate modules/Numbers.It is important to note that the signal routing should not cross the moat as much as possible, and that the returning current path of the power supply and signal should not be too large.

Crystal oscillators are analog positive feedback oscillating circuits. For stable oscillating signals, they must meet the specifications of loop gain and phase. The oscillating specifications of these analog signals are susceptible to interference, and even ground guard traces may not be able to completely isolate the interference. And too far away, the noise on the ground plane will also affect the positive feedback oscillation circuit.

Therefore, the distance between the crystal oscillator and the chip must be closer. Indeed, there are many conflicts between high-speed wiring and EMI requirements. However, the basic principle is that some electrical characteristics of the signal should not be inconsistent with the specification due to the resistance capacitance added by EMI or ferrite bead.Therefore, it is better to solve or reduce EMI problems by arranging wiring and PCB lamination, such as high-speed signal going to the inner layer. Finally, electric resistance or ferrite bead was used to reduce the damage to the signal.

10. About test coupon.

Test coupon is used to measure whether the characteristic impedance of the produced PCB board meets the design requirements with TDR (Time Domain Reflectometer).Generally, the impedance to be controlled is either a single line or a differential pair.

Therefore, the route width and spacing (with differential pairs) on the test coupon should be the same as the line you want to control. The most important thing is the location at which the measurement is made.

In order to reduce the inductance of the ground lead, the ground of the TDR probe is usually very close to the probe tip. Therefore, the distance between the measured signal point and the connection point on the test coupon and the way should be consistent with the used probe.

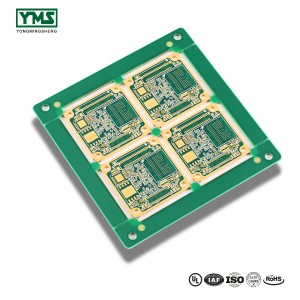

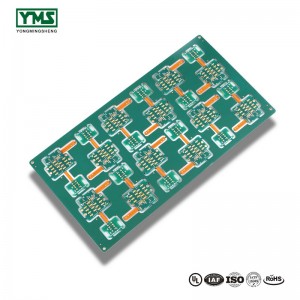

Yongmingsheng technology co., LTD. is a high-tech company integrating circuit board development, design, proofing, production (processing), testing, production and sales.

The main products are:high frequency PCB, flex-rigid, metal PCB, reasonable price;

Since the establishment of the company, from the original professional circuit board processing, to expand the production of flexible circuit board, rigid circuit board, etc. We have been making progress, we have been committed to become a high quality PCB manufacturer and service provider.

You May Like:

Post time: Sep-18-2019