Printed circuit board for fixed circuit, electrical layout optimization is important, then high frequency circuit, high frequency PCB advantage how to make it.

What is a printed circuit board made of

Printed circuit board is mainly composed of solder pad, through hole, mounting hole, conductor, components, connector, filling, electrical boundary, etc. The main functions of each component are as follows:

Welding pad: used for welding metal hole of component pin.

Through hole: metal through hole and non-metal through hole, in which metal through hole is used for connecting components and pins between layers.

Mounting hole: used for fixing circuit board.

Lead: copper film of electrical network used for connecting pins of components.

Connectors: components used for connecting circuit boards.

Filling: used for copper coating of ground wire network, which can effectively reduce impedance.

Electrical boundary: used to determine the size of the circuit board, all components on the circuit board must not exceed the boundary.

High frequency circuit board production principle

In high frequency circuit design, the power supply is designed in layers, which in most cases is much better than the bus design, so that the loop can always follow the path of least impedance.

In addition, the power board also needs to provide a signal loop for all the signals generated and received on the PCB, which can minimize the signal loop and thus reduce noise, which is often overlooked by low-frequency circuit designers.

In high frequency PCB design, we should follow the following principles:

Unification and stability of power supply and ground.

Careful wiring and proper end connections can eliminate reflections.

Careful wiring and proper end connections can reduce tolerances and perceptual crosstalk.

Noise suppression is required to meet EMC requirements.

High frequency PCB material requirements

1. The dielectric loss (Df) must be small, which mainly affects the quality of signal transmission. The smaller the dielectric loss is, the smaller the signal loss will be.

2. Low water absorption, high water absorption will affect the dielectric constant and dielectric loss when affected by moisture.

3. The dielectric constant (DK) must be small and very stable, usually the smaller the better. The signal transmission rate is inversely proportional to the square root of the material's dielectric constant.

4. As far as possible, it is consistent with the thermal expansion coefficient of copper foil, because inconsistency will cause copper foil separation in the change of cold and heat.

5. Other heat resistance, chemical resistance, impact strength, peel strength must be good.

In general, high frequency can be defined as frequency above 1GHz. At present, the most commonly used high frequency is fluorine plate dielectric substrate, such as polytetrafluoroethylene (PTFE), usually known as teflon.

High frequency circuit board processing attention

1. Impedance control requirements are strict, relative to the line width control is very strict, the general tolerance of about 2%.

2. Due to the special board, the adhesion of PTH copper deposition is not high. It is usually necessary to use plasma treatment equipment to roughened the hole and surface first, so as to increase the adhesion of PTH hole copper and solder ink.

3. Do not grind the board before resistance welding, otherwise the adhesion will be very poor, can only use micro corrosion potion and other rough.

4. Most of the plate is teflon material, with the general milling cutter molding will have a lot of burr, need special milling cutter.

5. High frequency circuit board is a special circuit board with higher electromagnetic frequency, generally speaking, high frequency can be defined as frequency above 1GHz.

Its various physical performance, precision, technical parameters are very high requirements, often used in automobile collision prevention system, satellite system, radio system and other fields.

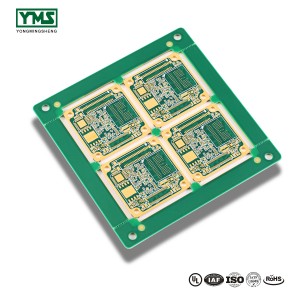

Yongmingsheng technology co., LTD. is a high-tech company integrating circuit board development, design, proofing, production (processing), testing, production and sales.

The main products are:single-layer PCB, double-layer PCB, heavy copper board, reasonable price;

Since the establishment of the company, from the original professional circuit board processing, to expand the production of flexible circuit board, rigid circuit board, etc. We have been making progress, we have been committed to become a high quality PCB manufacturer and service provider.

You May Like:

Post time: Sep-18-2019