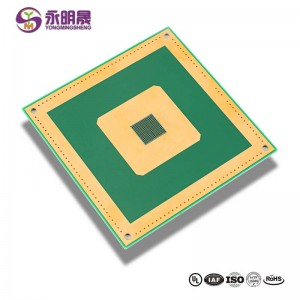

High Tg material PCB 6 Layer High Tg Board| YMS PCB

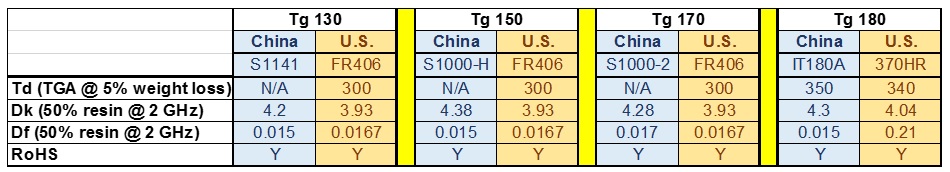

High-TG PCB Advanced Circuits Specification

The glass transition temperature of PCB, referred to as "Tg", indicates the point at which the PCB material will begin to transform. If the operating temperature exceeds the designated Tg value, the board will begin to change from a solid to a liquid state, which is likely to have an adverse effect on its ability to function.

Standard PCBs are manufactured with materials offering a TG value of 140°C, which can withstand an operating temperate of 110°C. While this may not be suitable for extreme-temperature processes that are commonplace in applications such as automotive, industrial or high-temperature electronics. In these situations, a PCB made from FR-4 High TG material can often provide the best solution.

YMS High Tg PCB manufacturing capabilities:

|

YMS High Tg PCB manufacturing capabilities overview |

||

| Feature | capabilities | |

| Layer Count | 3-60L | |

| Available Multilayer PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 TG 180°Mix etc. | |

| High Speed Material such as M7NE and FR4 TG 180°Mix etc. | ||

| Thickness | 0.3mm-8mm | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

You May Like:

1、PCB circuit board manufacturing packaging process

2、How to distinguish the quality of the PCB board

Learn more about YMS products

What is high Tg PCB material?

High Tg PCBs: Greater than 170°C with a typical range of 180°C to 225°C.

What is Tg and TD in PCB?

Tg is expressed in units of degrees Celsius (ºC). Decomposition temperature, or Td, is the temperature at which a PCB material chemically decomposes

What is standard Tg?

standard Tg:TG130-TG135°C