Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

The most traditional manufacturing process of semi-flex PCB is adopting the bending FR-4 materials and making PCB according to the traditional rigid PCB manufacturing process, and then using the deep milling technology to thin the areas that need to be bended so that it has a certain degree of flexibility, so as to meet the requirements of assembly bending connection.

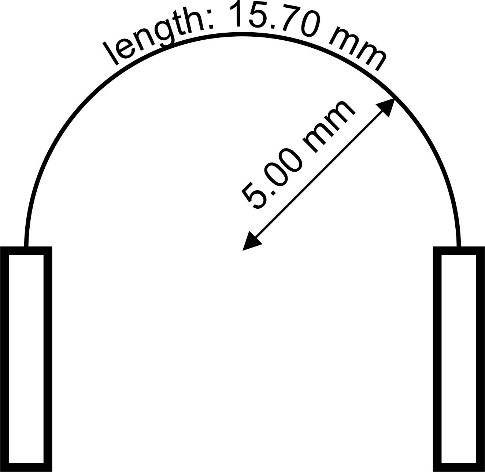

SEMI-FLEX length Calculator: (2 x Π x bend radius) x (bend angle/360°)

For example, bending 5 times over an angle of 180 degree with a radius of 5mm requires a minimum length of the semi-flex part of 15,7mm

YMS Semi-Flex PCB manufacturing capabilities:

| YMS Semi-Flex PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-20L,with 1 – 2 conductive layers in the flexible section | |

| Rigid-Flex Thickness | 0.5mm-5.0mm | |

| PCB thickness in flex section | 0.15-0.8mm ± 0.05mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 ,Aluminum etc. | |

| Material | FR4,RA copper, HTE copper, adhesive,Bondply,coverlayer, flex soldermask | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay |

|

Learn more about YMS products

Read more news

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.