Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

De stäerkste traditionell Fabrikatiounsprozess vun semi-FlexLanguage PCB ass Adoptioun vun der Béie FR-4 Materialien an nees PCB no der traditionell steiwe PCB Fabrikatiounsprozess, an dann mat der déif milling Technologie benotzt fir d'Gebidder ze dënnen déi gebéit musse ginn sou datt et huet e gewësse Grad vu Flexibilitéit, sou datt d'Ufuerderunge vun der Assemblée Biegsverbindung gerecht ginn.

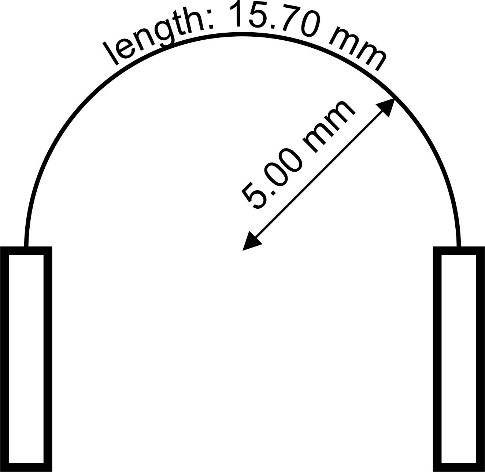

SEMI-FLEX Längt Rechner: (2 x Π x Béi Radius) x (Béien Wénkel / 360 °)

Zum Beispill, 5 Mol ze béien iwwer e Wénkel vun 180 Grad mat engem Radius vu 5 mm erfuerdert eng Mindestlängt vum semi-flexen Deel vun 15,7 mm

YMS Semi-Flex PCB Fabrikatiounskapazitéiten :

| YMS Semi-Flex PCB Fabrikatiounsfäegkeeten Iwwersiicht | ||

| Fonktioun | Fäegkeeten | |

| Schicht Grof | 2-20L , mat 1 - 2 leitend Schichten am flexiblen Deel | |

| Steiwe-Flex Décken | 0.5mm-5.0mm | |

| PCB Dicken am Flex Sektioun | 0,15-0,8 mm ± 0,05 mm | |

| Koffer Déck | 1 / 4OZ-10OZ | |

| Minimum Linn Breet a Weltraum | 0.05mm / 0.05mm (2mil / 2mil) | |

| Steifwierker | Edelstahl, PI, FR4, Aluminium etc. | |

| Material | FR4, RA Koffer, HTE Koffer, Klebstoff, Bondply, Deckelayer, flex Lötmask | |

| Min mechanesch Boormooss | 0.15mm (6mil) | |

| Min Laser Lächer Gréisst: | 0,075mm (3mil) | |

| Uewerfläch fäerdeg | Geeignet Mikrowelle / RF PCB Uewerfläch fäerdeg: Elektrolos Nickel, Immersion Gold, ENEPIG, Lead gratis HASL, Immersion Silver.etc. | |

| Solder Mask | Gréng, Rout, Giel, Blo, Wäiss, Schwaarz, Purpur, Matt Schwaarz, Matt Gréng. | |

| Covrelay (Flex Deel) | Giel Coverlay, WhiteCoverlay, Black Coverlay |

|

Léiert méi iwwer YMS Produkter

Liest méi Neiegkeeten

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.