Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Ang pinaka-tradisyonal na proseso ng pagmamanupaktura ng semi-flex PCB ay gumagamit ng baluktot na mga materyales na FR-4 at ginagawa ang PCB ayon sa tradisyunal na mahigpit na proseso ng pagmamanupaktura ng PCB, at pagkatapos ay ginagamit ang malalim na teknolohiya ng paggiling upang mapayat ang mga lugar na kailangang baluktot kaya't mayroon itong isang tiyak na antas ng kakayahang umangkop, upang matugunan ang mga kinakailangan ng koneksyon sa baluktot ng pagpupulong.

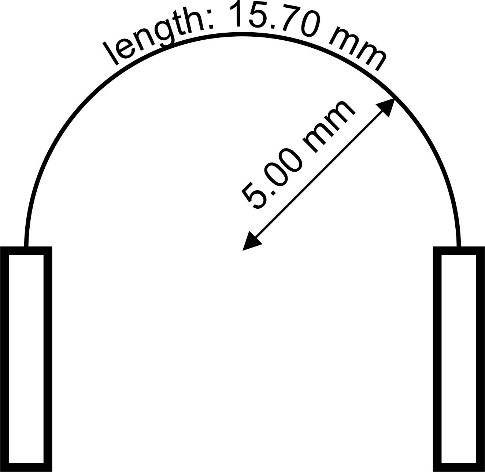

Calculator ng haba ng SEMI-FLEX: (2 x Π x radius ng liko) x (anggulo ng liko / 360 °)

Halimbawa, ang baluktot na 5 beses sa isang anggulo ng 180 degree na may radius na 5mm ay nangangailangan ng isang minimum na haba ng semi-flex na bahagi ng 15,7mm

YMS Semi-Flex PCB manufacturing capa bilities:

| Pangkalahatang-ideya ng mga kakayahan sa pagmamanupaktura ng YMS Semi-Flex PCB | ||

| Tampok | mga kakayahan | |

| Bilang ng Layer | 2-20L, na may 1 - 2 conductive layer sa nababaluktot na seksyon | |

| Kapal ng Flex-Flex | 0.5mm-5.0mm | |

| Kapal ng PCB sa seksyon ng flex | 0.15-0.8mm ± 0.05mm | |

| tanso Kapal | 1 / 4OZ-10OZ | |

| Minimum na linya ng Lapad at Puwang | 0.05mm / 0.05mm (2mil / 2mil) | |

| Mga Stiffener | Hindi kinakalawang na asero , PI , FR4 , Aluminium etc. | |

| Materyal | FR4, RA na tanso, HTE na tanso, malagkit, Bondply , coverlayer, flex soldermask | |

| Min na Laki ng mekanikal na Drilled | 0.15mm (6mil) | |

| Min Laki ng butas ng laser: | 0.075mm (3mil) | |

| Tapos na sa Labas | Mga angkop na Micartz / RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL, Immersion Silver.etc. | |

| Panghinang Mask | Green, Pula, Dilaw, Asul, Puti, Itim, Lila, Matte Itim, Matte berde. Atbp. | |

| Covrelay (Bahagi ng Flex) | Dilaw na Coverlay, WhiteCoverlay, Itim na Coverlay |

|

Matuto pa tungkol sa mga produkto ng YMS

Magbasa pa ng balita

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.