Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

Najtradicionalniji proizvodni postupak polufleksne PCB-a je usvajanje savijajućih FR-4 materijala i izrada PCB-a prema tradicionalnom krutom procesu proizvodnje PCB-a, a zatim upotrebom tehnologije dubokog glodanja za razrjeđivanje područja koja treba saviti tako da se određeni stupanj fleksibilnosti, kako bi se udovoljilo zahtjevima sklopnog priključka za savijanje.

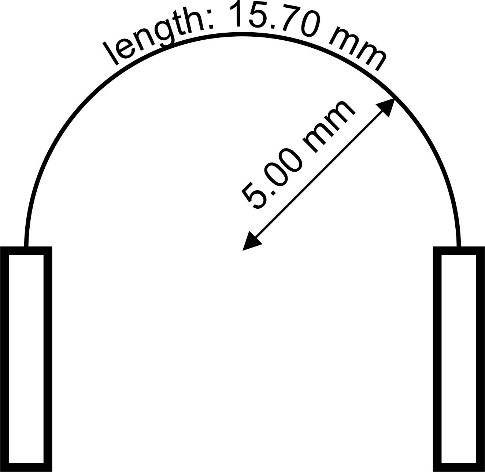

SEMI-FLEX kalkulator duljine: (2 x Π x polumjer savijanja) x (kut savijanja / 360 °)

Na primjer, savijanje 5 puta pod kutom od 180 stupnjeva s radijusom od 5 mm zahtijeva minimalnu duljinu polufleksnog dijela od 15,7 mm

Sadržaji Semi-Flex PCB proizvodnju sposobno :

| Pregled proizvodnih mogućnosti YMS Semi-Flex PCB-a | ||

| Značajka | mogućnosti | |

| Broj slojeva | 2-20L , s 1 - 2 vodljiva sloja u fleksibilnom dijelu | |

| Debljina krutog savijanja | 0,5 mm-5,0 mm | |

| Debljina PCB-a u flex dijelu | 0,15-0,8 mm ± 0,05 mm | |

| Debljina bakra | 1 / 4OZ-10OZ | |

| Minimalna širina linije i razmak | 0,05 mm / 0,05 mm (2 mil. / 2 mil.) | |

| Učvršćivači | Nehrđajući čelik , PI , FR4 , Aluminij itd. | |

| Materijal | FR4, RA bakar, HTE bakar, ljepilo, Bondply , pokrovni sloj, fleks maska za lemljenje | |

| Min. Mehanička veličina bušenja | 0,15 mm (6 mil.) | |

| Minimalna veličina laserskih rupa: | 0,075 mm (3 mil) | |

| Završna obrada | Prikladni završni slojevi za mikrovalne / RF PCB: bezelektrični nikal, uronjeno zlato, ENEPIG, bezolovni HASL, uronjeni srebro itd. | |

| Maska za lemljenje | Zelena, crvena, žuta, plava, bijela, crna, ljubičasta, mat crna, mat zelena.itd. | |

| Covrelay (Flex dio) | Žuta navlaka, bijela navlaka, crna navlaka |

|

Saznajte više o YMS proizvodima

Pročitajte više vijesti

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.