Flex rigid Board semi flex PCB Black Soldermask| YMSPCB

What is Semi-Flex PCB?

O proceso de fabricación máis tradicional do PCB semi-flex é adoptar os materiais de flexión FR-4 e fabricar o PCB segundo o proceso tradicional de fabricación do PCB ríxido e, a continuación, empregar a tecnoloxía de fresado profundo para diluír as áreas que hai que dobrar para que teña un certo grao de flexibilidade, para satisfacer os requisitos da conexión de flexión de montaxe.

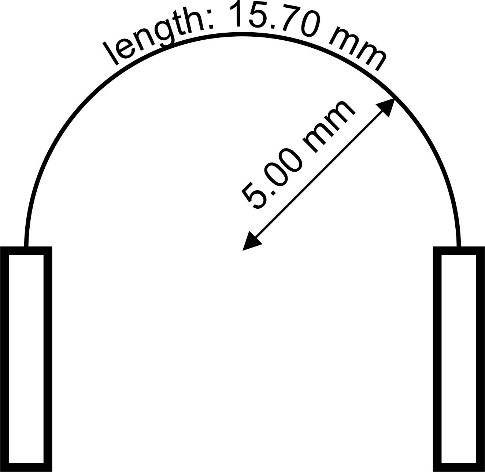

Calculadora de lonxitude SEMI-FLEX: (2 x Π x radio de curvatura) x (ángulo de curvatura / 360 °)

Por exemplo, dobrar 5 veces sobre un ángulo de 180 graos cun raio de 5 mm require unha lonxitude mínima da parte semiflex de 15,7 mm

Capacidades de PCB semi-flexibles manufacturing capa:

| Descrición xeral das capacidades de fabricación de PCB Semi-Flex YMS | ||

| Función | capacidades | |

| Reconto de capas | 2-20L , con 1-2 capas condutoras na sección flexible | |

| Espesor ríxido-flexible | 0,5 mm-5,0 mm | |

| Grosor de PCB en sección flex | 0,15-0,8 mm ± 0,05 mm | |

| Espesor de cobre | 1 / 4OZ-10OZ | |

| Ancho e espazo mínimo da liña | 0.05mm / 0.05mm (2mil / 2mil) | |

| Refrixerantes | Aceiro inoxidable , PI , FR4 , Aluminio etc. | |

| de materiais | FR4, cobre RA, cobre HTE, adhesivo, capa Bondply ,, máscara sold sold | |

| Tamaño mínimo perforado mecánico | 0,15 mm (6 millas) | |

| Tamaño mínimo de buratos láser: | 0,075 mm (3mil) | |

| Acabado superficial | Adecuados acabados de superficie de microondas / PCB RF: níquel sen electrolixe, ouro por inmersión, ENEPIG, HASL sen chumbo, inmersión Silver.etc. | |

| Máscara de soldar | Verde, vermello, amarelo, azul, branco, negro, roxo, negro mate, verde mate.etc. | |

| Covrelay (parte flexible) | Coverlay amarelo, WhiteCoverlay, Coverlay negro |

|

Máis información sobre os produtos YMS

Ler máis noticias

What is a rigid flex board?

The rigid-flex board is a flexible circuit board(FPC) and a rigid circuit board (PCB), which are combined together according to the relevant process requirements through pressing and other processes in the PCB proofing to form a circuit board with FPC characteristics and PCB characteristics.

What is difference between rigid and flexible boards?

As the names suggest, a rigid PCB is a circuit board built on a rigid base layer that cannot bend, while a flexible PCB, also called a flex circuit, is built on a flexible base capable of bending, twisting and folding.

Where are rigid flex PCBs used?

You’ll find them in commercial, industrial and military applications. From digital cameras to cell phones to smart devices, they serve them all. Especially in the medical industry for developing pacemakers for their weight reduction, space, and flexible capabilities.