Rigid flex pcb multilayer flexible pcb HDI Any-Layer PCBs stacked vias | YMSPCB

What is a Rigid Flex PCB?

Rigid-Flex printed circuit boards are boards using a combination of flexible and rigid board technologies in an application.

The proper application of Rigid-Flex circuit boards offers optimum solutions for difficult, limited space conditions. This technology offers the possibility of a secure connection of device components with the assurance of polarity and contact stability, as well as a reduction in plug and connector components.

Additional advantages of Rigid-Flex circuit boards are dynamic and mechanical stability, the resulting 3-dimensional freedom of design, simplified installation, space savings, and maintenance of uniform electrical characteristics.

Parameters

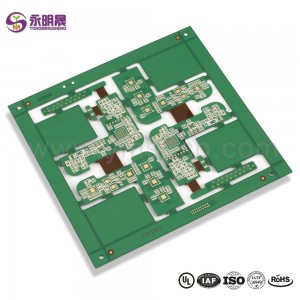

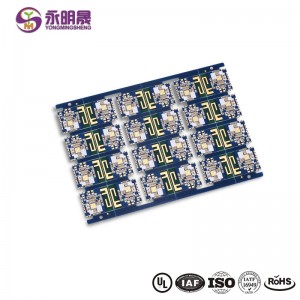

Layers: 8L rigid flex pcb

Board Thinkness:0.69mm+/-0.1mm

PCB thickness in flex section:0.5mm+/-0.05mm

Base Material:PI+FR4pp

Min laser Holes:0.075mm(3mil)

Min mechanical Holes:0.15mm

Minimum Line Width/Clearance:0.046mm/0.046mm( 1.8mil/1.8mil)

Minimum Clearance between Inner Layer PTH and Line: 0.175mm

Size:160.92mm×145mm

Aspect Ratio:4.6 : 1

Surface treatment:ENIG

Speciality: rigid flex pcb multilayer fpc HDI Any-Layer PCBs stacked vias, Fine circuit 1.8mil, High Density Interconnect PCB 1.8mil/1.8mil,Laser via copper plated shut

Differential impedance 100+7/-8Ω

Applications: Medical stimulator

YMS Rigid Flex PCB manufacturing capabilities:

| YMS Rigid Flex PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

Learn more about YMS products

Read more news

What is a flex PCB?

Flexible PCBs (FPC) are the PCBs that can be bent or twisted without damaging the circuits, which means the boards can be bent freely to conform to the desired shape during applications. The material the substrate used is flexible, such as Polyamide, PEEK, or a conductive polyester film.