Flex rigid pcb HDI Rigid Flex PCB| YMS PCB

What is a Rigid Flex PCB?

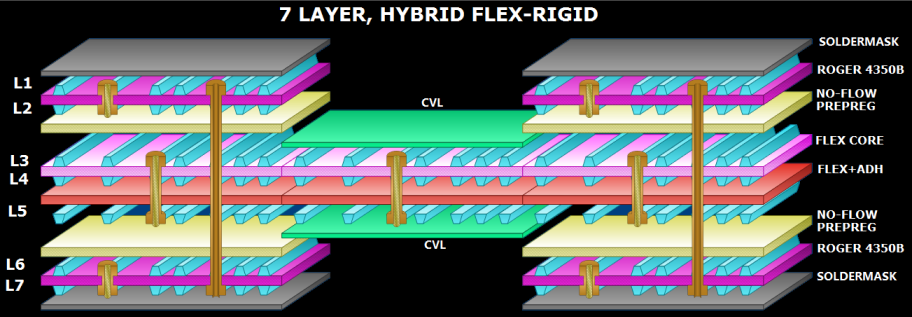

Rigid-Flex printed circuit boards are designed to provide solutions, and act as replacements for rigid PCBs. As the name suggests, these circuit boards are a hybrid of flex and rigid circuits. The advantage of this type is that they exhibit the benefits of both rigid as well as flexible circuit boards.

YMS Rigid Flex PCB manufacturing capabilities:

| YMS Rigid Flex PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 ,Aluminum etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

Learn more about YMS products

What is a flex PCB?

Flexible PCBs (FPC) are the PCBs that can be bent or twisted without damaging the circuits, which means the boards can be bent freely to conform to the desired shape during applications. The material the substrate used is flexible, such as Polyamide, PEEK, or a conductive polyester film.

Write your message here and send it to us