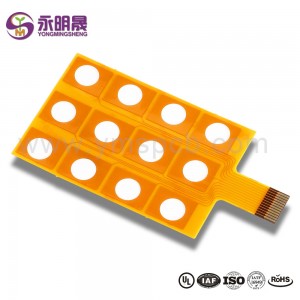

Bendable,2Layer Flexible Printed Circuit Board | YMSPCB

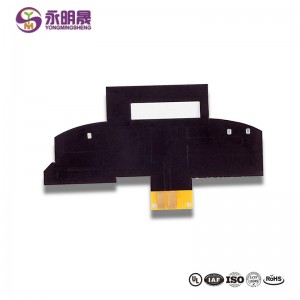

Flexible Material Slicing

Most flexible board materials are rolling format.For different demanding, makers need to optimize the utilization.The first step in making FPC is slicing flexible material to working size.Roll-to-roll manufacturing is used to some mass-produced FPC and then the slicing procedure can be eliminated.

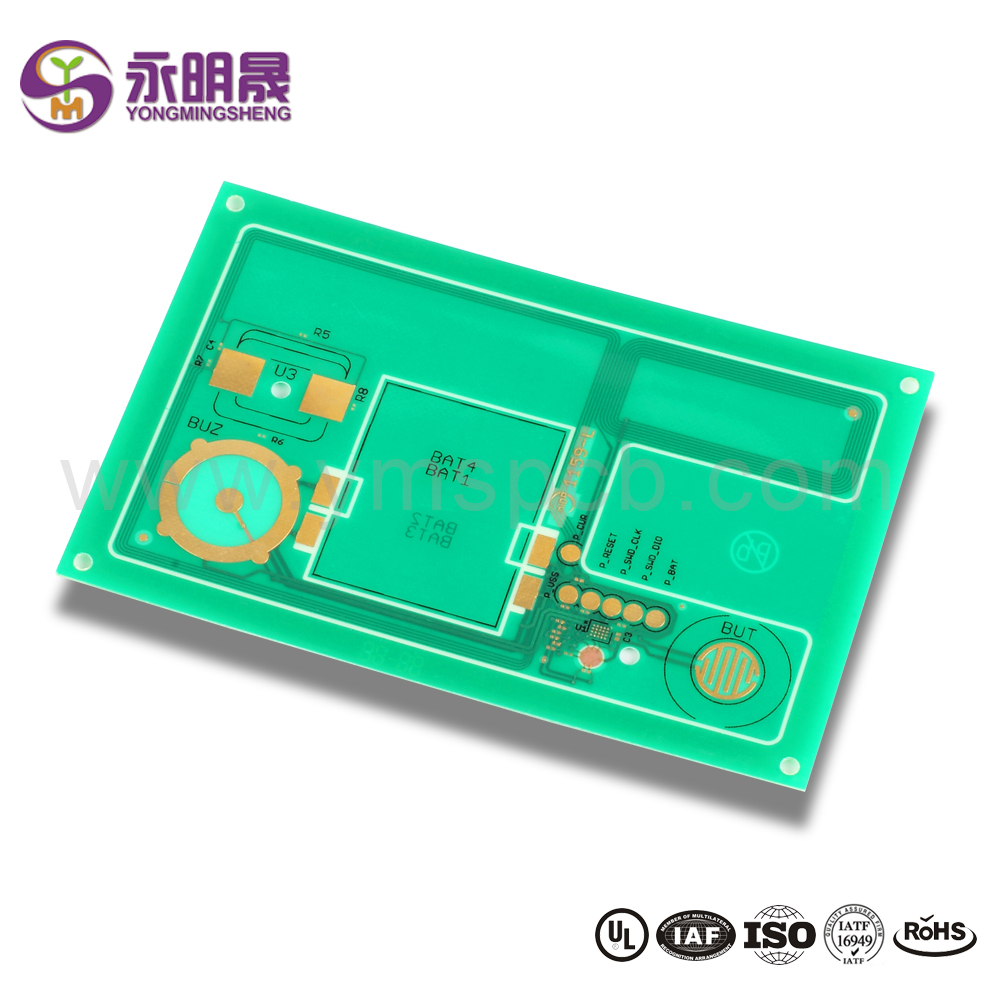

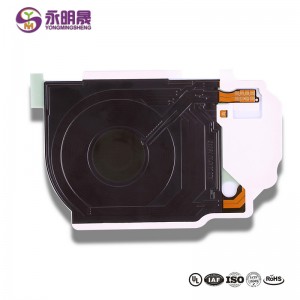

What is a flex PCB stiffener?

The purpose of the stiffener is to strengthen the mechanical strength of FPC (flexible circuit board) on account of facilitating the mounting of components on the PCB surface, etc.The types of stiffener used in the flexible circuit board are various, which mainly depends on the requirements of the product, such as PET, PI, adhesive, metal or resin stiffener, etc.

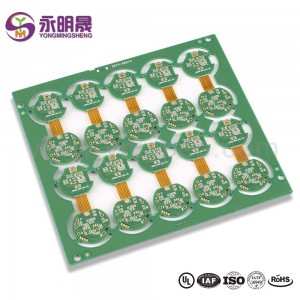

Flexible PCBs (FPC) are the PCBs that can be bent or twisted without damaging the circuits, which means the boards can be bent freely to conform to the desired shape during applications. The material the substrate used is flexible, such as Polyamide, PEEK, or a conductive polyester film. In many cases, flex circuits are made of polyimide or a similar polymer. This material dissipates heat better than most rigid circuit board materials. For this reason, flexible circuits can be placed in inconvenient locations where heat would impact the performance of a rigid circuit board. Flexible circuit boards can be designed to withstand extreme temperatures – between -200° C and 400° C – which explains why they are so desirable for borehole measurements in the oil and gas industry.

In fact, because of these conditions, and the need for small, unobtrusive devices in most industrial environments, flexible circuits represent the first choice for engineering design in most industrial sensor technologies.

High-temperature resistance comes usually comes with good chemical resistance and excellent resistance to radiation and UV exposure as well. Combined with the ability to control impedances in high-density circuit board designs, flexible circuit designs offer many benefits to manufacturers.

Learn more about YMS products

Video

Are there flexible circuit boards?

Flexible circuits members of electronic and interconnection family.

What are flex PCBs used for?

FPCs are lighter than rigid PCBs and can be designed to smaller sizes for its flexibility. These advantages make FPCs available to replace bulky circuits in some applications. For example, FPCs can be used in Satellites, where the weight and volume are the main limitations for designers. What’s more, LED strips, consumer electronics, automobiles, and many other high-density applications favor flexible boards to reduce the size and weight.

What are flexible circuit boards made of?

The dielectric layers in FPCs are typically homologous sheets of flexible polyimide material. While The dielectric materials in rigid PCBs are usually the composite of epoxy and glass fiber woven cloth.