Flex Circuit,1Layer Flexible Printed Circuit Board | YMSPCB

What is a FPC?

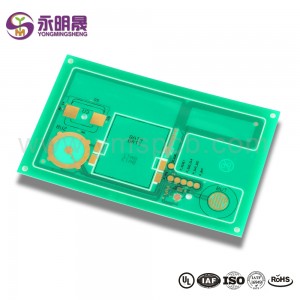

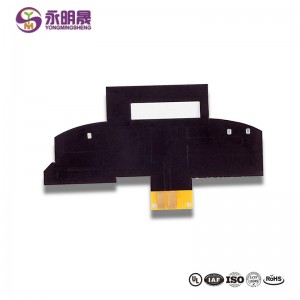

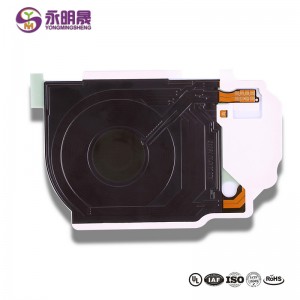

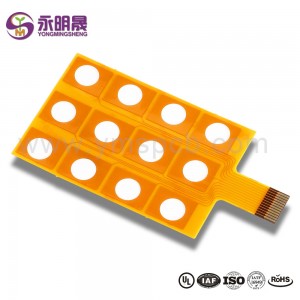

Flexible Printed Circuits (FPCs), also called Flexible Circuits, or Flex Circuits, by IPC definition, a flexible printed circuit is a patterned arrangement of printed circuitry and components that utilizes flexible based material with or without flexible cover lay. This definition is accurate, and conveys some of the potential given the available variations in base materials, conductor materials, and protective cover materials. But sometimes, flexible circuits are also called as Flexible PCB or Flex PCB, that’s because the inherent concept of most people is that flexible circuit is a bendable printed circuit board (PCB) consisting of a flexible film with a pattern of copper conductors on it. In reality, a flexible printed circuit consists of a metallic layer of traces, usually copper (rarely constantan), bonded to a dielectric layer, usually polyimide (rarely polyester). Of course, a multilayer flex circuit can contain many metallic layers. As a flex circuit manufacturer, YMSPCB can fabricate 8-layer flex PCB. Thickness of the conductive layer can be very thin (0.47mil, 12μ, 1/3oz) to very thick (2.8mil, 70μ, 2oz) and the dielectric thickness can vary from 0.5mil (13μ) to 5mil (125μ). Flexible copper clad laminates (FCCL) can be single-sided and double-sided with or without a layer of adhesive to bond the metal to the substrate. Flexible circuits (FPC) are used in a multitude of applications, ranging from the lowest end consumer products to the highest end military and commercial systems. It is no coincidence that the ranges of materials used to fabricate these circuits are as diverse in performance as the range of products in which they are used. Flexible PCBs are widely used in electronic devices as an indispensable component offering the benefits of being compact, thin, and highly pliable. As a reliable flexible circuit manufacturer, we support all kinds of 1-8 layers flexible circuits manufacturing, including flex circuits with thru-hole interconnection, buried and/or blind via interconnection, buried and blind microvia interconnection. Moreover, YMSPCB supports carbon ink, silver ink, constantan, and hatch impedance controlled flexible circuits.

Different Copper Foils Used in Flex Circuit

[Process Description]

The copper foil used in the FPC depends on the applications.

[General Procedure]

Copper foil material used in normal PCB has two types, electrodeposited copper foil and rolled copper foil, and used in different applications.Rolled copper foil is used in dynamic flexible production for its compactness and flexure resistance.

Electrodeposited copper foil is used in non-dynamic flexure applications Rolled copper foil manufacturing process will create much stress and then need annealing.After annealing, rolled copper foil has suitable grain structure to prevent crack propagation.That's why it has flexure resistance.

Video

Learn more about YMS products