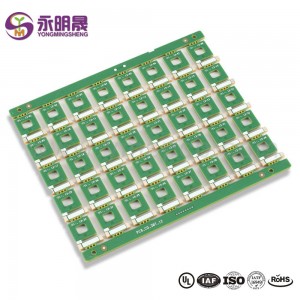

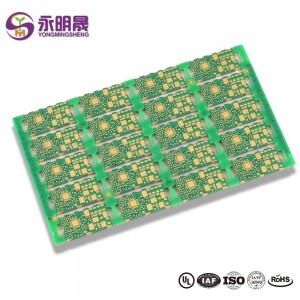

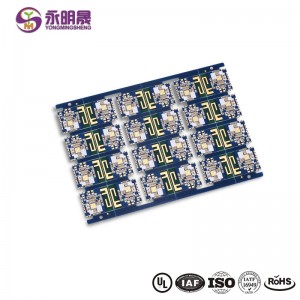

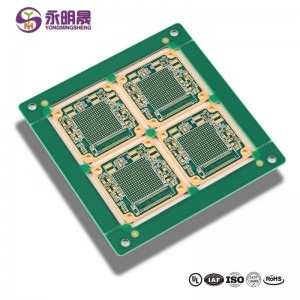

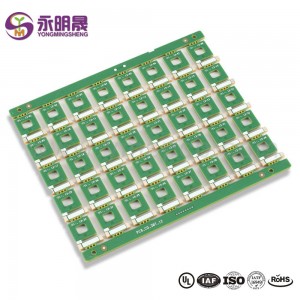

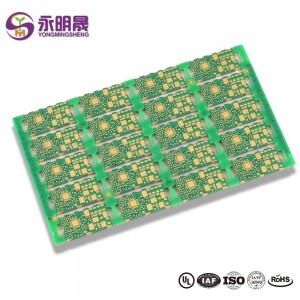

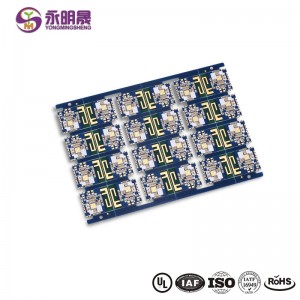

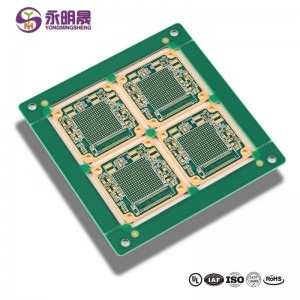

YMS is the company you can trust for the best in printed circuit boards in china for use in advanced electronics. We specialize in the design and production of multilayer printed circuit boards, Of course ,we also can handle more complex PCB ,such as HDI PCB,FPC,Rigid-flex PCB as well as Aluminum base PCB .If you need your PCBs in hand as fast as possible, you can trust YMSPCB.

Our highly trained assembly technicians specialize in multilayer circuit boards. They use state-of-the-art multilayer circuit board fabrication equipment to ensure that the finished boards we distribute meet your exacting standards and technical specifications. You will also find that our multilayer PCB price fits your project budget.