Yaya Kauri 1oz Copper yake?

A cikin masana'antar da'ira da aka buga, hanyar da aka fi sani don bayyana kauri tagulla akan PCB ita ce oza (oz). Me yasa amfani da naúrar nauyi don tantance kauri? Babbar tambaya! Idan 1oz (gram 28.35) na jan ƙarfe ya baje ko'ina don rufe ƙafar murabba'in ƙafa 1 na fili (0.093 murabba'in mita), sakamakon kauri zai zama 1.37mils (0.0348mm). Za a iya samun ginshiƙi juyi don raka'a ma'auni daban-daban a ƙasa.

Jadawalin Canjin Kauri na Copper

|

oz |

1 |

1.5 |

2 |

3 |

4 |

5 |

6 |

| mil |

1.37 |

2.06 |

2.74 |

4.11 |

5.48 |

6.85 |

8.22 |

| inci |

0.00137 |

0.00206 |

0.00274 |

0.00411 |

0.00548 |

0.00685 |

0.00822 |

| mm |

0.0348 |

0.0522 |

0.0696 |

0.1044 |

0.1392 |

0.1740 |

0.2088 |

| µm |

34.80 |

52.20 |

69.60 |

104.39 |

139.19 |

173.99 |

208.79 |

Nawa Copper nake bukata?

Ta tazara mai faɗi, yawancin PCBs ana yin su da jan karfe 1oz akan kowane Layer. Idan fayilolinku ba su haɗa da bugu ko wasu ƙayyadaddun bayanai ba, za mu ɗauka 1oz ya gama nauyin jan karfe akan duk yaduddukan tagulla. Idan ƙirar ku tana buƙatar mafi girman ƙarfin lantarki, juriya, ko impedances, ƙaramin jan ƙarfe na iya zama dole. Akwai kayan aikin kan layi da yawa waɗanda za su iya taimaka muku sanin wane kauri, faɗi ko tsayin sawun ku ya zama don cimma sakamakon da kuke so. Ana haɗe kaɗan irin waɗannan kayan aikin ɓangare na uku a ƙasa. PCB Prime bashi da alaƙa da marubutan waɗannan kayan aikin.

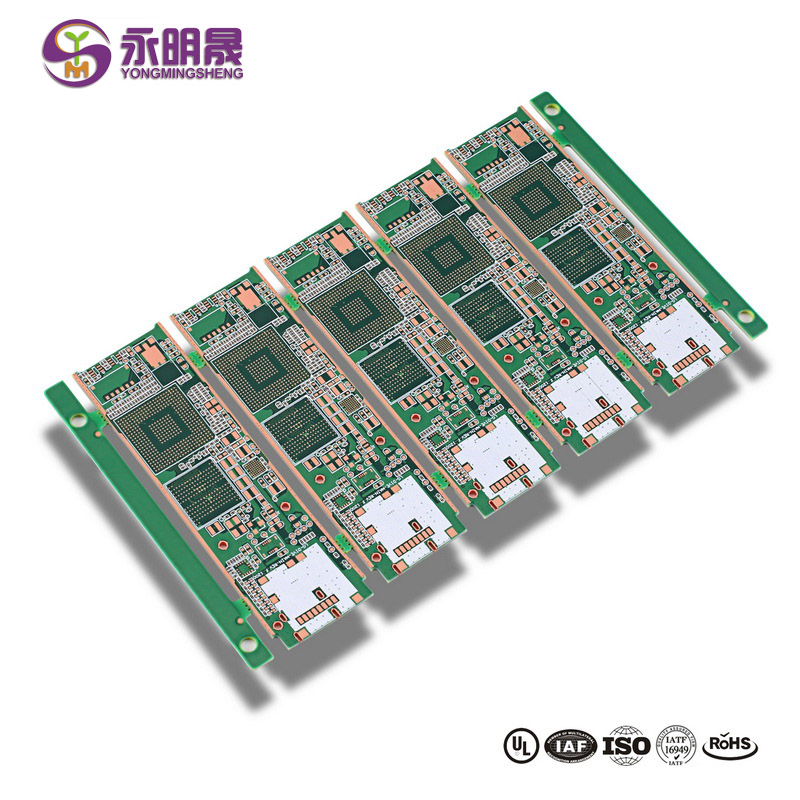

Rarraba Copper

A matsayinka na yau da kullum, ya kamata a rarraba jan karfe daidai da yadda zai yiwu a cikin zane-zane. Ba wai kawai game da kauri na jan karfe akan kowane Layer ba, har ma da yadda ake rarraba shi a fadin Layer. Tabbas, wannan ba koyaushe yana yiwuwa ba, amma kiyaye wannan a hankali yayin shimfidawa.

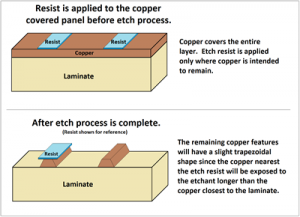

Plating da etching tsari ne na kwayoyin halitta a ma'anar cewa lamintin tagulla yana nutsar da shi a cikin kwandon sinadarai don sarrafawa. Babu madaidaicin iko akan inda aka cire tagulla ko farantin karfe. A lokacin etch, hoton da aka yi niyya ana rufe shi don kare shi daga fashewa, amma sinadaran da ke cikin tanki suna narkar da tagulla a farashi daban-daban dangane da inda fasalin yake a kan panel, wurin sanya panel a cikin tankin da kansa, da kuma yadda yake da yawa. ko kadan an rarraba sifofin tagulla.

Maganin sinadarai a cikin tankuna na plating da etching suna tada hankali kuma suna yawo yayin aiki don rage waɗannan rashin daidaituwa; duk da haka, kwamitin da ke da nau'ikan tagulla daban-daban na iya tabbatar da matsala. Yayin lokacin ƙirar ku, yi ƙoƙarin rarraba tagulla a ko'ina a cikin dukkan allo maimakon samun manyan wuraren buɗe ido tare da keɓantattun siffofi.

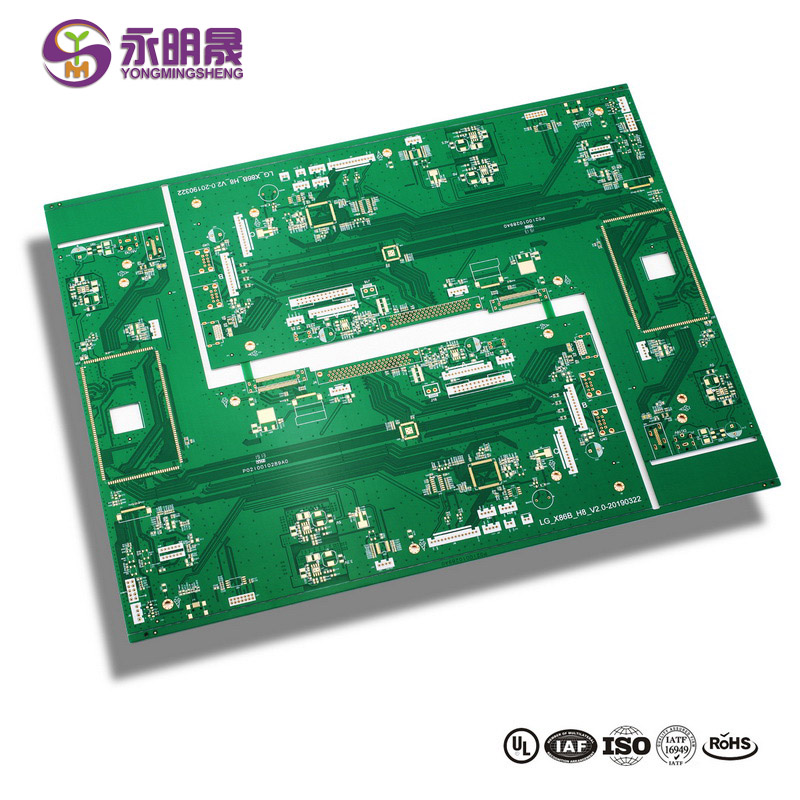

YADDA AKE ZABEN KASAR PCB TASKAR KASHI

Zaɓin mafi kyawun kauri mai nauyi na jan ƙarfe don amfani da wanda aka yi wa plated ta rami (PTH) yana taka muhimmiyar rawa ga ɗaukacin amincin allon da'irar da aka buga. Akwai mahimman abubuwa guda biyu da za a yi la'akari da su lokacin tantance mafi kyawun kauri na tagulla na PCB. Na farko shine ƙarfin halin yanzu na ganga don karɓuwar zafi mai karɓa. Na biyu shi ne ƙarfin injin da aka ƙaddara ta kauri na jan ƙarfe, girman rami da ko akwai tallafin vias ko a'a.

Yawancin abokan ciniki suna son gina PCBs tare da kyakkyawan aiki akan farashi mai tsada. Mataki na farko shine zaɓar kauri mai dacewa da tagulla don nau'in PCB ɗin ku. Siffofin musamman na waɗannan kauri suna da mahimmanci wajen ƙayyade ayyuka, aikin PCBs. Idan kuna son ƙarin bayani game da zaɓin kauri na tagulla na PCB ko yadda za ku zaɓi mafi dacewa da ƙirar PCB ɗinku, da fatan za a tuntuɓe mu. Muna ba da shawara mai kyau ba kawai amma cikakkiyar bayani. Za ku sami ƙananan PCBs masu wayo tare da kyakkyawan aiki da babban abin dogaro daga YMS.

Ƙara koyo game da samfuran YMS

Mutane kuma suna tambaya

Lokacin aikawa: Maris 23-2022