PCBs na yumbu sun ƙunshi yumbura mai yumbu, layin haɗin gwiwa, da madaurin kewaye. Ba kamar MCPCB ba, PCBs yumbu ba su da abin rufe fuska, kuma kera da'irar da'ira akan yumbura yana da wahala. Ta yaya ake kera PCBs yumbura? Tun da an yi amfani da kayan yumbura azaman kayan aikin PCB, an ƙirƙiri wasu ƴan hanyoyi don kera layin da'irar akan yumbu. Waɗannan hanyoyin sune HTCC, DBC, fim mai kauri, LTCC, fim ɗin bakin ciki, da DPC.

HTCC

Ribobi: babban ƙarfin tsarin; high thermal watsin; kyakkyawan kwanciyar hankali sunadarai; babban yawan wayoyi; RoHS ya tabbatar

Fursunoni: rashin ƙarfi na kewaye; high sintering yanayin zafi; tsada tsada

HTCC taƙaitaccen yumbu ne mai tsananin zafin jiki. Ita ce farkon hanyar masana'anta PCB yumbura. Kayan yumbu na HTCC sune alumina, mullite, ko aluminum nitride.

Tsarin masana'anta shine:

A 1300-1600 ℃, yumbu foda (ba tare da ƙara gilashin) an sintered da bushe don ƙarfafawa. Idan zane yana buƙatar ta cikin ramuka, ana zubar da ramuka a kan katako na substrate.

A daidai wannan yanayin zafi, ƙarfe mai zafi mai zafi yana narke a matsayin manna karfe. Karfe na iya zama tungsten, molybdenum, molybdenum, manganese, da sauransu. Karfe na iya zama tungsten, molybdenum, molybdenum, da manganese. Ana buga fakitin ƙarfe bisa ga ƙira don samar da layin da'irar a kan madaurin kewaye.

Bayan haka, ana ƙara taimakon sintering 4%-8%.

Idan PCB ɗin multilayer ne, yadudduka ana lanƙwasa.

Sa'an nan a 1500-1600 ℃, dukan hade ne sintered samar da yumbu kewaye allon.

A ƙarshe, ana ƙara abin rufe fuska don kare tsarin kewaye.

Bakin Fim Ceramic PCB Manufacturing

Ribobi: ƙananan zafin jiki na masana'antu; m kewaye; kyau surface flatness

Fursunoni: kayan masana'anta masu tsada; ba zai iya kera da'irori mai girma uku ba

Layer na jan karfe akan sikirin fim ɗin yumbu na PCBs yana da kauri ƙasa da 1mm. Babban kayan yumbu don sirara-fim yumbu PCBs sune alumina da aluminum nitride. Tsarin masana'anta shine:

An fara tsaftace kayan yumbura.

A cikin yanayi mara kyau, danshi a kan yumbura yana ƙafe da zafi.

Bayan haka, an kafa wani Layer na jan karfe a saman yumbura ta hanyar sputtering magnetron.

Hoton kewayawa an yi shi ne akan layin jan karfe ta hanyar fasahar photoresist mai launin rawaya.

Sannan ana cire jan karfe da ya wuce kima ta hanyar etching.

A ƙarshe, ana ƙara abin rufe fuska don kare kewaye.

Takaitawa: An gama masana'antar fim ɗin yumbu na bakin ciki PCB a cikin yanayin injin. Fasahar lithography mai haske ta rawaya tana ba da ƙarin daidaito ga kewayawa. Koyaya, masana'anta-fim na bakin ciki suna da iyaka zuwa kaurin jan ƙarfe. Sirin-fim yumbu PCBs sun dace da madaidaicin marufi da na'urori a cikin ƙarami.

DPC

Ribobi: babu iyaka ga nau'in yumbu da kauri; m kewaye; ƙananan zafin jiki na masana'antu; kyau surface flatness

Fursunoni: kayan aiki masu tsada masu tsada

DPC ita ce taƙaitaccen jan ƙarfe da aka yi da shi kai tsaye. Yana tasowa daga hanyar samar da yumbu na fim na bakin ciki kuma yana inganta ta hanyar ƙara kauri na jan karfe ta hanyar plating. Tsarin masana'anta shine:

Tsarin masana'anta iri ɗaya na masana'antar fim na bakin ciki har sai an buga hoton kewayawa akan fim ɗin jan karfe.

Ana ƙara kauri na jan ƙarfe ta kewaye ta plating.

An cire fim ɗin jan ƙarfe.

A ƙarshe, ana ƙara abin rufe fuska don kare kewaye.

Kammalawa

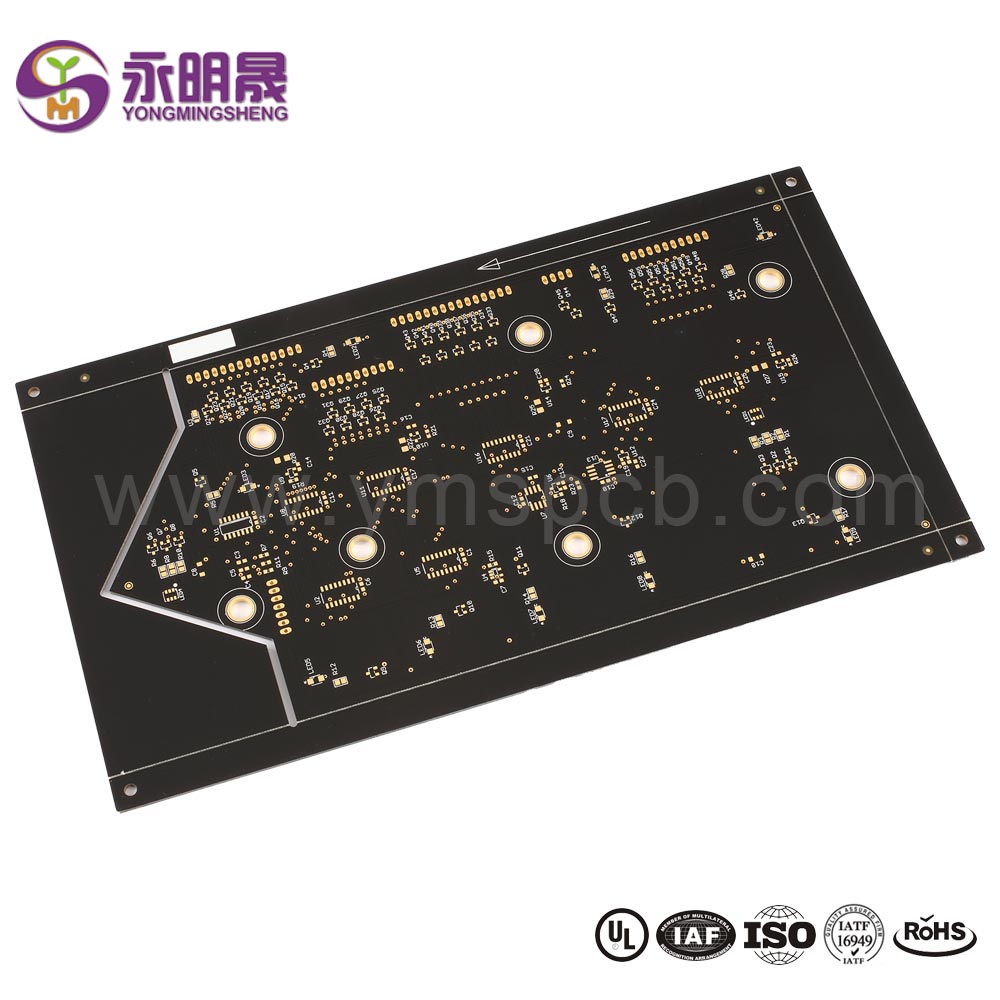

Wannan labarin ya lissafa hanyoyin masana'anta PCB na yumbu na gama gari. Yana gabatar da hanyoyin masana'anta na PCB yumbu kuma yana ba da taƙaitaccen bincike akan hanyoyin. Idan injiniyoyi / mafita kamfanoni / cibiyoyi suna son a ƙera PCBs na yumbura da kuma haɗa su, YMSPCB zai kawo musu sakamako mai gamsarwa 100%.

Bidiyo

Ƙara koyo game da samfuran YMS

Mutane kuma suna tambaya

Lokacin aikawa: Fabrairu-18-2022