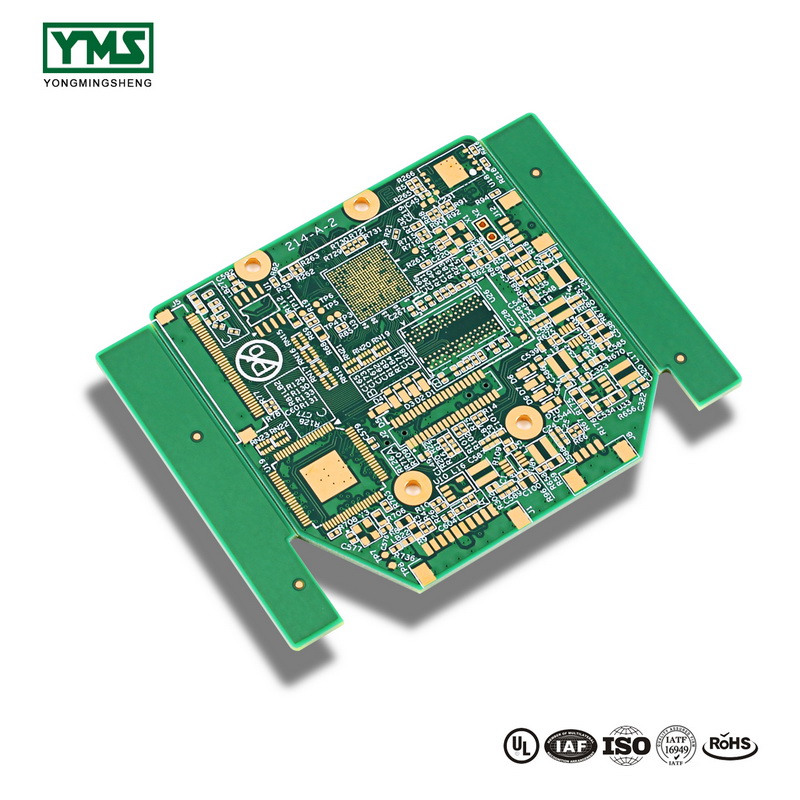

HDI PCB: non-mechanical drilling, microblind hole ring less than 6mil, inner and outer layer wiring line width. When the gap is less than 4mil and the diameter of the welding pad is no more than 0.35mm, the multilayer production method is called HDI board.

Blind hole: short for Blind via, realizing the connection between inner layer and outer layer.

The structure of the structure is Buried via a large blind hole.

They are all small holes with diameters of 0.05mm~0.15mm. The hole forming methods of the buried blind hole include laser hole forming, plasma erosion hole forming and photoinduced hole forming. Usually, laser hole forming is adopted, and laser hole forming is divided into CO2 and YAG ultraviolet laser machine (UV).

The first and second order of the six layers are for the plates that need laser drilling, namely the HDI board.

6 HDI board of first order

Blind hole: 1-2, 2-5, 5-6. Namely, 1-2, 5-6 need laser drilling.

6 layers of second order HDI board

Blind hole: 1-2, 2-3, 3-4, 4-5, 5 -6.

First drill the buried hole of 3-4, then press 2-5, then drill the laser hole of 2-3, 4-5 for the first time, then press 1-6 for the second time, then drill the laser hole of 1-2, 5-6 for the third time.

Finally the hole is drilled. It can be seen that the second-order HDI board has been pressed twice and drilled twice by laser.

Classification of second-order HDI board:

Double-hole second-order HDI board and double-hole second-order HDI board, double-hole second-order HDI board means blind hole 1-2 and 2-3 are staggered, while double-hole second-order HDI board means blind hole 1-2 and 2-3 are stacked together, for example: blind hole 1-3, 3-4, 4-6.

We are committed to being a high quality HDI PCB manufacturer and service provider.

Post time: Sep-23-2019