News

-

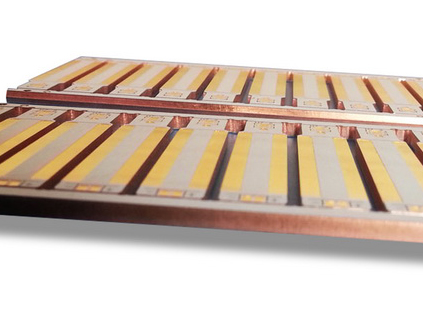

Copper base board and aluminum base board difference | YMSPCB

Copper base board and aluminum base board difference 1. The thermal conductivity of copper base board is twice that of aluminum base board. The higher the thermal conductivity is, the higher the thermal conductivity is, and the better the heat dissipation function is. 2....Read more -

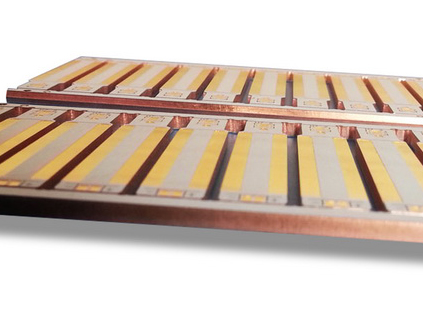

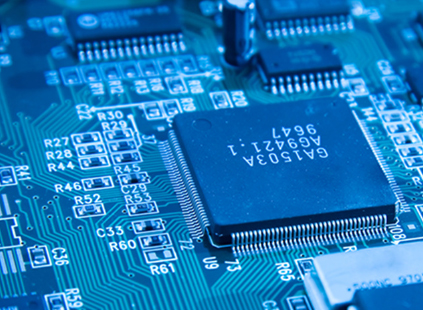

Understand the construction of heavy copper PCB | YMSPCB

Heavy copper PCB is made with 4 or more ounces of copper per layer. 4 oz copper PCB is most commonly used in commercial products. Copper concentrations can be as high as 200 ounces per square foot. Heavy copper PCB is widely used in electronics and circuits requiring hig...Read more -

Common reasons for PCB to dump copper | YMSPCB

There are several common reasons for PCB factory to dump copper: I. PCB factory manufacturing process factors: 1. Excessive etching of copper foil, the electrolytic copper foil used in the market is generally single-sided galvanized (commonly known as ash foil) and singl...Read more -

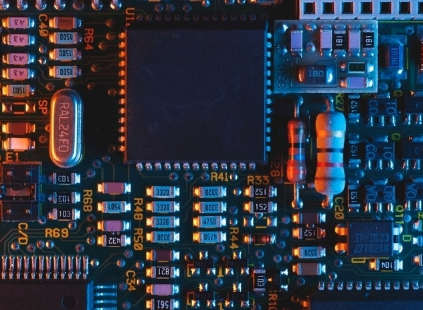

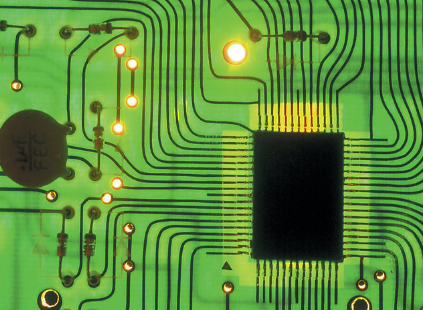

PCB coated with copper knowledge tips | YMSPCB

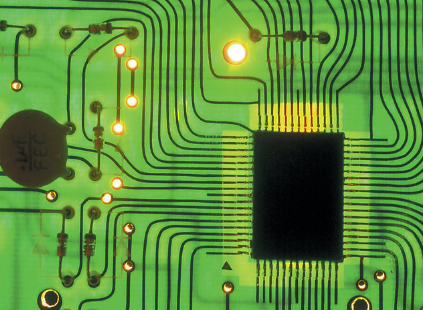

Copper coating is a common procedure that covers areas of a printed circuit board that are not wired with copper. This can enhance the anti-interference performance of the printed circuit board. By copper coating, the unused space on the PCB is used as a base level and t...Read more -

9 attention points of copper application | YMSPCB

By copper coating, the unused space on the PCB is used as the base level and then filled with solid copper, which is also known as copper pouring. The significance of copper coating lies in reducing ground resistance, improving anti-interference ability, reducing voltag...Read more -

What are the requirements for copper thickness of PCB orifice | YMSPCB

The holes on the printed circuit board are generally divided into those with copper holes and those without copper holes, which are mainly used for positioning and installation, and generally belong to relatively large holes, more than 0.8mm. And the through hole general...Read more -

PCB hole copper fracture reason | YMSPCB

PCB hole copper Hole copper is the hole with metallization requirements, by electroplating the hole with a layer of copper, so that the two sides of the hole can be conducted, the layer of copper in the hole is called hole copper. PCB hole copper fracture reason 1. Local...Read more -

PCB copper coating experience

Copper-coating, in which unused space on a PCB is used as a base level and then filled with solid copper, is called copper pouring. The significance of copper coating lies in reducing ground resistance, improving anti-interference ability, reduceing voltage drop, improvi...Read more -

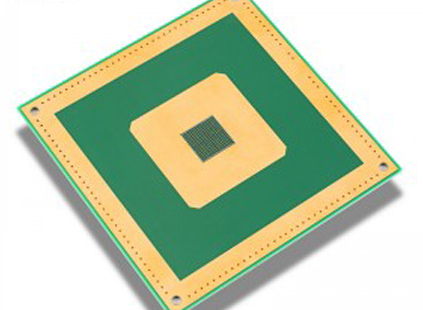

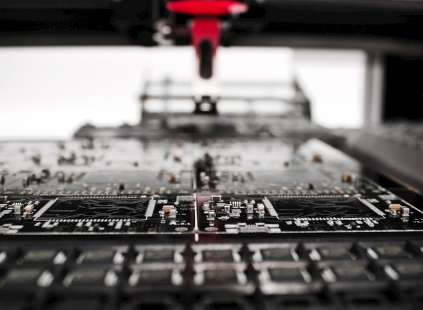

Study on improving small hole machining of copper base PCB board

With the increasing requirement of high-power electronic components for PCB cooling ability, the market's demand for metal base board is also rising, and higher processing requirements are also put forward for copper based PCB products. Especially in the aspect of drilli...Read more