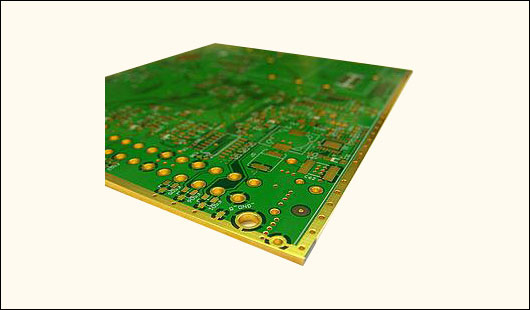

Edge Plating PCB 10 Lakabka Lakabka cidhifka PCB| YMS PCB

Waa maxay PCB Edge Plating?

Dajinta cidhifka PCB waa habka isku xidhka sare iyo hoose ee PCB iyadoo la isticmaalayo koronto ku wareegsan cidhifyada dibadda ee PCB-ga. Habkan waxa kale oo loo magacaabi karaa sida dhinac-dajinta, dahaadhaynta xuduudka, biraynta geesaha, ama koontoor la dhejiyay. Aaladaha leh shuruudaha dhexdhexaadka ah ama kuwa sare ee EMC, hufnaanta calaamadaha, iyo daadinta kulaylka, dajinta cidhifku waxay leedahay faa'iidooyin muuqda oo qiimo jaban ah. Caadi ahaan, ENIG ama nikkel-dahab ayaa lagula talinayaa inay noqdaan habka dhammaystirka dusha sare ee daminta cidhifka.

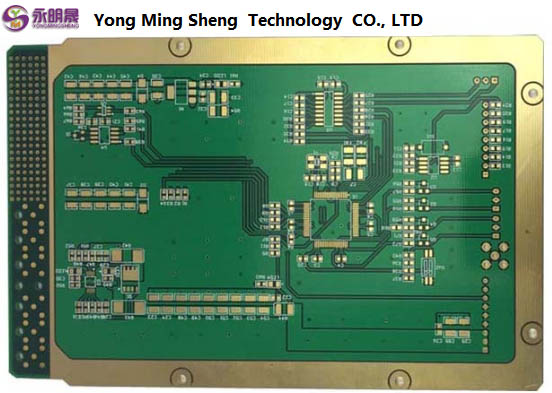

NIDAAMKA PCB-ga ee ku dhejinta cidhifyada

Samaynta looxa wareegyada daabacan ee alxanka cidhifku waxay u baahan tahay in si sax ah loo maareeyo waxayna wajahdaa caqabado badan oo ku saabsan sida cidhifyada loo diyaariyo iyo ku dhegganaanta walaxda dahaadhsan.

MCL waxa ay dejisay dhaqamada warshadaha oo ay u soo saartay heerarkan si loo hubiyo in PCB-ga qalfoofka cidhifka ahi si fiican u diyaariyo sagxadaha cidhifka ah, oo ay ku dabaqdo naxaasta dahaadhka ah si loogu dhejiyo isla markaaba guddida si loo hubiyo ku-dhejinta lakab kasta.

By using a controlled process in our circuit board fabrication for edge soldering, we can limit any potential hazard for through-holes and half-holes on the edge. The most significant concern is the creation of burrs, which will lead to the failure of mission-critical parts and can damage your equipment.

CODSIGA

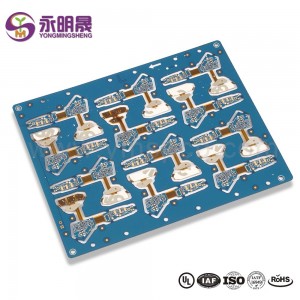

Looxyada wareegyada cidhifyada waxay ku badan yihiin warshado badan, dajinta cidhifkuna waa dhaqan caadi ah. Waxaad ka heli doontaa PCB-ga qalcadda (ama PCB-yada cidhifka ah) oo lagu dabaqay xaalado badan, oo ay ku jiraan:

Hagaajinta awoodaha-qaadista hadda

Xidhiidhada cirifka iyo ilaalinta

Alxanka cidhifka si loo horumariyo been-abuurka

Taageero ka sii wanaagsan oo loogu talagalay isku xirka sida looxyada ku silba daasadaha birta ah

Fadlan ogow in cidhifyada cidhifka ah ee looxyada wareegyada daabacan ay tahay mid fudud oo lagu daro xaalado badan, laakiin waxay u baahan tahay qalab gaar ah iyo tababar. Waa ikhtiyaar loogu talagalay looxyo badan oo kala duwan, laakiin waxaan had iyo jeer ku talinaynaa in codsiga noocan oo kale ah loo qaado soo saaraha, sida MCL, oo leh sumcad la aasaasay oo ah castelation guddiga wareegga.

Waxaan awood u yeelan doonaa inaan samayno hubinta injineernimada saxda ah si aan wax walba u ilaalino. Tusaale ahaan, castelation board board waa in aanu waligiis keenin in diyaaradaha korantada gudaha ay yimaadaan cidhifka looxa, sababtoo ah waxay gaabin kartaa daminta cidhifka. Markaad safrayso, mar walba maskaxda ku hayso farqiga. Marka aan samayno samaynta sabuuradda wareegga ee alxanka cidhifka, waxaan had iyo jeer hubinnaa in ay jirto meel bannaan ka hor dahaadhka cidhifka. Meelaynta cidhifku waxay caawisaa abuurista xidhiidh adag oo PCB-yada waxayna yarayn kartaa fursada guuldarada aaladaha. Sidaa darteed, dhejinta cidhifyada ayaa si weyn loogu isticmaalaa codsiyada halka isku xirka u baahan yahay in si wanaagsan loo taageero oo uu noqdo dhaqan caadi ah wax soo saarka PCB . YMS waxay bixisaa qalab xirfadleyaal ah iyo injineero takhasus leh si ay u sameeyaan habka jeexista dhinaca. Fadlan ii soo dir iimayl ama la xidhiidh adeegyadayada khadka si aad u hesho tafaasiil dheeraad ah oo ku saabsan habka meelaynta cidhifka iyo cabbirrada naqshadaynta.

Xaddid

Sababtoo ah wax-soo-saarayaashu waxay u baahan yihiin inay ku qabtaan looxyada wareegga gudaha guddiga wax soo saarka ee PCb, ma dhejin karaan cidhifka dhererka dhammaystiran. Sidaa darteed, waxaa jira daldaloolo loo baahan yahay si loo dhigo tabs rout. Waxay u baahan tahay wareejinta profile guddiga wareegga goobta marka la samaynayo looxyada wareegga oo leh xayndaab cidhif ah , iyo dajinta cidhifka ayaa loo baahan yahay ka hor inta aan la bilaabin habka daloolka daloolka, kaas oo ka saaraya dhibcaha v-cut ee PCB kaas oo u baahan in la mariyo dajinta cirifka. .

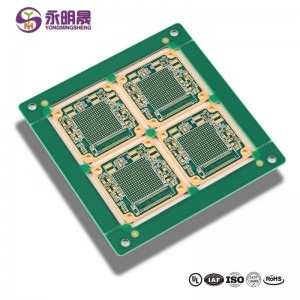

PCB-ga cidhifka ah ee YMS

In ka badan 10 sano oo ah hoggaamiye warshadeed, YMS waxay leedahay waayo-aragnimo badan oo wax soo saar ah oo loogu talagalay dajinta cirifka PCB, waxaanan awoodnaa inaan xakameyno tayada sare leh ee dajinta cidhifyada iyada oo aan lahayn burrs. Sababtoo ah ku qanacsanaanta macaamiishu waa yoolkeena, waxaan isku dayi doonaa sida ugu fiican inaan u abuurno guddigaaga tayada ugu sareysa si aan u daboolno baahiyahaaga oo aan u hoggaansanno heerarka ugu adag ee PCB-ga soo saarista iyo isku-dhafka.

YMS, oo ah lamaanaha ugu fiican ee injineerka elektiroonigga ah, ayaa ku siinaysa samaynta PCB qiimo jaban oo tayo sare leh.

Waxaad laga yaabaa:

1. Sida loo sameeyo inta jeer ee PCB

Video

Baro wax badan oo ku saabsan alaabta YMS

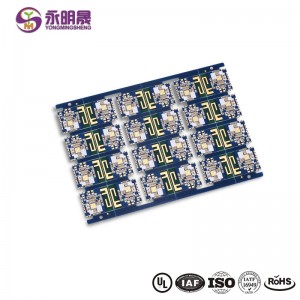

Waa maxay daminta cidhifka PCB?

Waxaa laga yaabaa inaad maqashay fikraddan loo yaqaan "dajinta cidhifyada" ama "castelation," taas oo ah dhejinta naxaasta ee ka socota korka ilaa dusha hoose ee PCB, oo ku socda ugu yaraan mid ka mid ah geesaha wareegyada. Qalab cidhifeedka PCB waxay hubisaa isku xidhka adag ee looxa waxayna xaddidaysaa fursada cilladaha qalabka, gaar ahaan xakamaynta ilaalinta looxyada qaab-yar ee qaabka yar yar iyo Motherboard-yada hoose.

Waa maxay dajinta naxaasta ee PCB?

Dajinta naxaasta waa hab-raac kiimiko-electro-chemical ah, kaas oo lakabka naxaasta ah lagu shubo dusha macdan ee adag ee adag iyadoo la isticmaalayo hadda korontada.

Dajinta naxaasta waa hab muhiim ah sababtoo ah:

Waxay bixisaa ilaalinta daxalka qiimo leh.

Waxay wanaajisaa iska caabbinta xidhashada ee dusha sare.

Waxay leedahay adhesion aad u fiican inta badan biraha salka, hagaajinta ductility ee alaabta dahaarka leh.

Waxay leedahay kuleyl heer sare ah iyo korantada korantada, taasoo ka dhigaysa alaabada dhejiska ah ee ku habboon codsiyada injineernimada saxda ah, sida looxyada wareegyada daabacan (PCB).