Ukuba i- PCB ongaphezulu, kukho i-SGND, i-AGND, i-GND, njl., kuxhomekeke kwindawo yobuso be- PCB , "umhlaba" oyintloko usetyenziswa njengesalathiso sokugquma ubhedu oluzimeleyo, oko kukuthi, umhlaba udityaniswe kunye. .

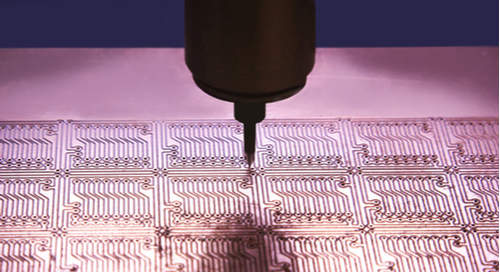

Izakhelo zokuPlayitha zobhedu

Ulwakhiwo oluzaliswe nge-pad lufuna ngemingxuma yobhedu ecakwe ukuze kuhanjiswe imiqondiso phakathi kweemaleko kwi-PCB ye-multilayer. Le plating idibanisa kwezinye iipads kwi- via-in-pad izakhiwo, kunye ngokuthe ngqo kumkhondo usebenzisa i-ring annular encinci. Ezi zakhiwo ziyimfuneko, kodwa ziyaziwa ukuba zineengxaki ezithile zokuthembeka phantsi kwebhayisekile ephindaphindiweyo yokufudumala.

Imigangatho ye-IPC 6012E isandula ukongeza imfuneko yokugquma ubhedu kwizakhiwo ze-pad. Ucwecwe olugcweleyo lobhedu kufuneka luqhubeke lujikeleze umda womngxunya kwaye ludlulele kwiringi ye-annular ejikeleze i-pad. Le mfuno iphucula ukuthembeka kwe-Plating kwaye inamandla okunciphisa ukusilela ngenxa yeentanda, okanye ngenxa yokwahlula phakathi kweempawu zomphezulu kunye nokucandwa ngomngxuma.

Izakhiwo zokugoqa ubhedu ezizaliswe zivela kwiindidi ezimbini. Okokuqala, ifilimu yobhedu eqhubekayo ingafakwa ngaphakathi kwi-via, ethi igqume phezulu kunye neengqimba ezisezantsi ekupheleni kwe-via. Le plating yobhedu yenza i-pad kunye nomkhondo okhokelela kwi-via, idala ulwakhiwo lobhedu oluqhubekayo.

Kungenjalo, indlela edlulayo inokuba nephedi yayo eyahlukileyo eyenziwe malunga neziphelo zendlela. Lo maleko wepadi ohlukeneyo udibanisa kwimizila okanye iindiza zomhlaba. Ucwecwe lobhedu oluzalisa indlela edlulayo emva koko isonge ngaphezulu kwale pad yangaphandle, yenze idibaniso yempundu phakathi kweplating yobhedu yokuzalisa kunye ne-pad. Olunye unxibelelwano lwenzeka phakathi kweplating yokuzalisa kunye ne-pad, kodwa ezi zimbini azidibanisi kunye kwaye azenzi isakhiwo esinye esiqhubekayo.

Kukho izizathu ezininzi zokucwangciswa kobhedu:

1. I-EMC. Kummandla omkhulu womhlaba okanye ubhedu lwamandla, luya kukhusela, kunye nezinye ezikhethekileyo, ezifana ne-PGND ukukhusela.

2. Iimfuno zenkqubo yePCB. Ngokuqhelekileyo, ukuze kuqinisekiswe ukuba i-plating isiphumo, okanye i-laminate ayikhubeki, i-copper ibekwe kwi-PCB kunye ne-wiring encinci.

3. Iimfuno zengqibelelo yesiginali, zinika umqondiso wedijithali we-high-frequency indlela epheleleyo yokubuya, kunye nokunciphisa i-wiring ye-intanethi ye-DC. Ngokuqinisekileyo, kukho ukutshatyalaliswa kobushushu, ukufakwa kwesixhobo esikhethekileyo kufuna i-copper plating kunye nokunye.

Inzuzo enkulu ye-copper plating kukunciphisa i-impedance yomgca womhlaba (into ebizwa ngokuba yi-anti-interference nayo ibangelwa inxalenye enkulu yokunciphisa i-impedance line). Kukho imisinga ye-spike eninzi kwisekethe yedijithali, ngoko ke kuyimfuneko kakhulu ukunciphisa i-impedance yomgca womhlaba. Kukholelwa ngokubanzi ukuba iisekethe ezenziwe ngokupheleleyo ngezixhobo zedijithali kufuneka zibekwe phezu kwendawo enkulu, kwaye kwiisekethe ze-analog, iluphu yomhlaba eyenziwe ngokutyalwa kobhedu inokubangela uphazamiseko lokudibanisa i-electromagnetic lube ngaphantsi (ngaphandle kweesekethe eziphezulu zefrikhwensi). Ngoko ke, akusiyo isiphaluka esimele sibe yibhedu (BTW: i-mesh copper ingcono kunebhloko yonke).

Ukubaluleka kokufakwa kobhedu lwesekethe:

1. ubhedu kunye nocingo lomhlaba odibeneyo, oku kunokunciphisa indawo ye-loop

2. indawo enkulu yokucoca ubhedu ilingana nokunciphisa ukuchasana kocingo lomhlaba, ukunciphisa ukunyanzeliswa koxinzelelo kula manqaku mabini Kuthiwa ukuba umhlaba wedijithali kunye nomhlaba we-analog kufuneka ube ngobhedu ukunyusa amandla okuchasana nokuphazamiseka, kwaye at ama-frequencies aphezulu, umhlaba wedijithali kunye nomhlaba we-analog kufuneka uhlukaniswe ukubeka ubhedu, kwaye emva koko uqhagamshelwe ngenqaku elilodwa, indawo enye inokusebenzisa ucingo ukwenza ukujika okumbalwa kwindandatho yamagnetic uze udibanise. Nangona kunjalo, ukuba i-frequency ayiphezulu kakhulu, okanye iimeko zokusebenza zesixhobo azikho zimbi, unokuphumla kancinci. I-crystal ingabalwa njengomthombo we-high-frequency kwisekethe. Ungabeka ubhedu ngeenxa zonke kwaye ucofe ilitye lekristale, elingcono.

Ukuba unomdla wokufunda ngakumbi malunga neYMS PCB, qhakamshelana nathi nangaliphi na ixesha.

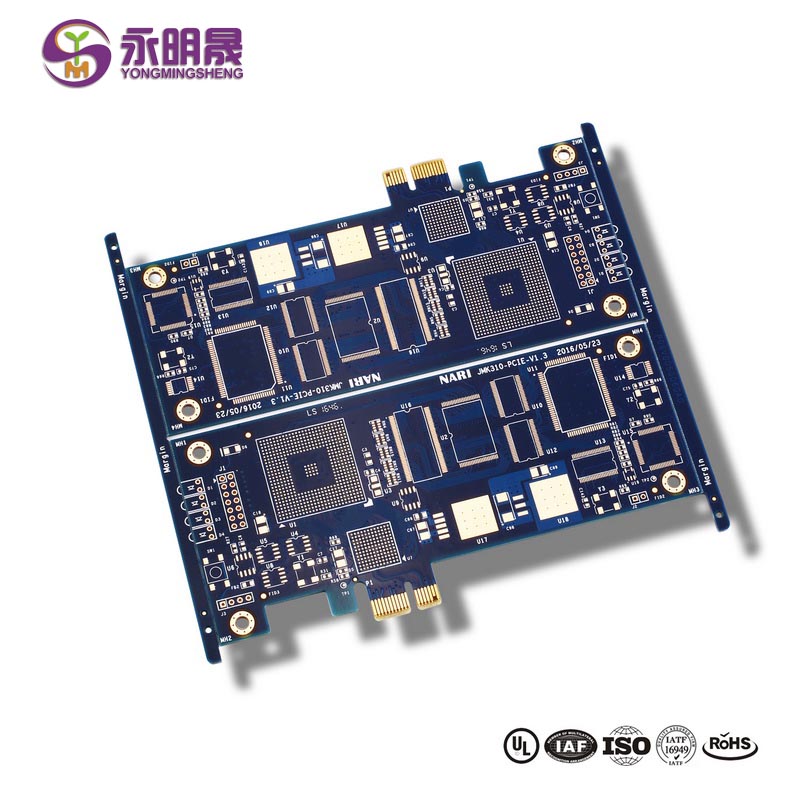

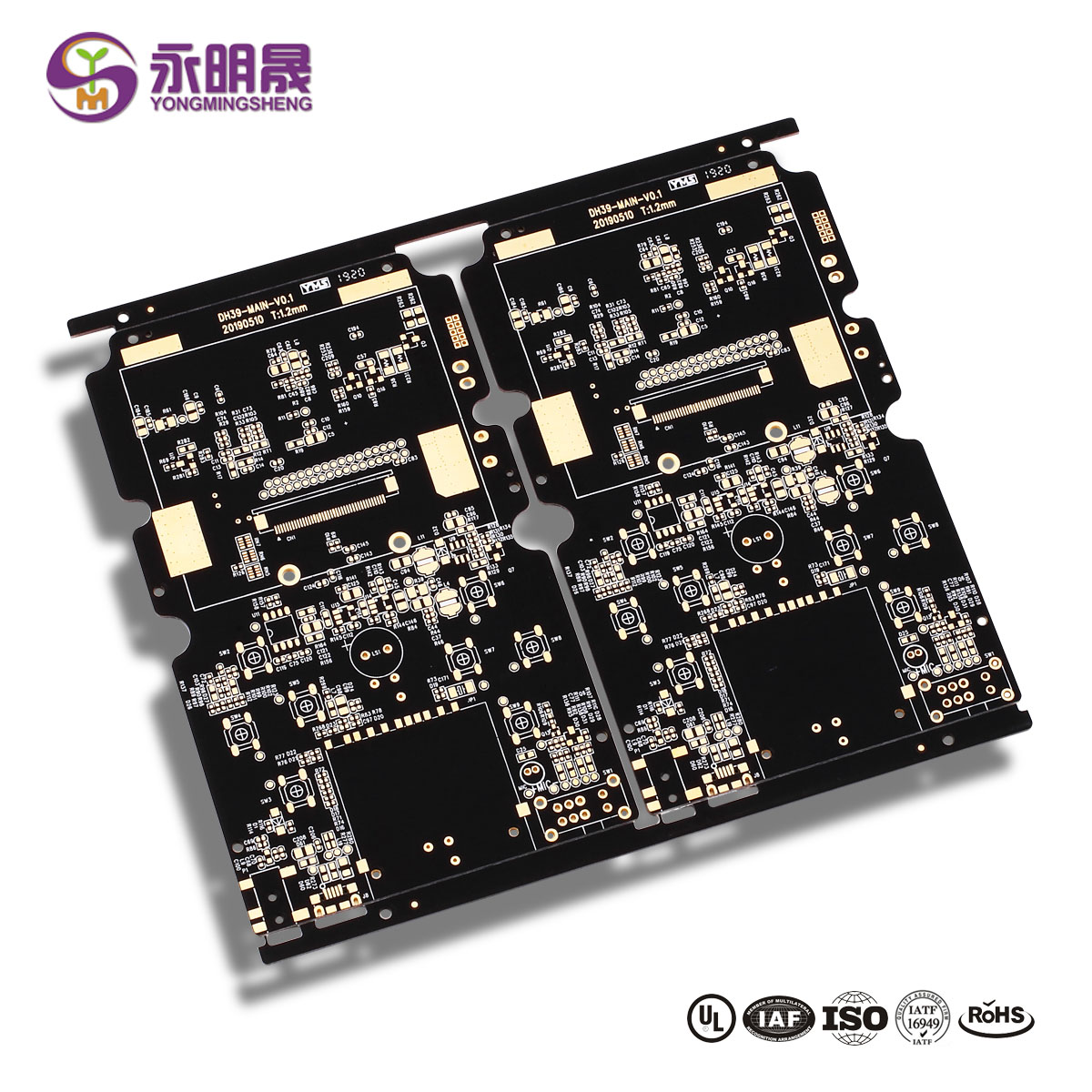

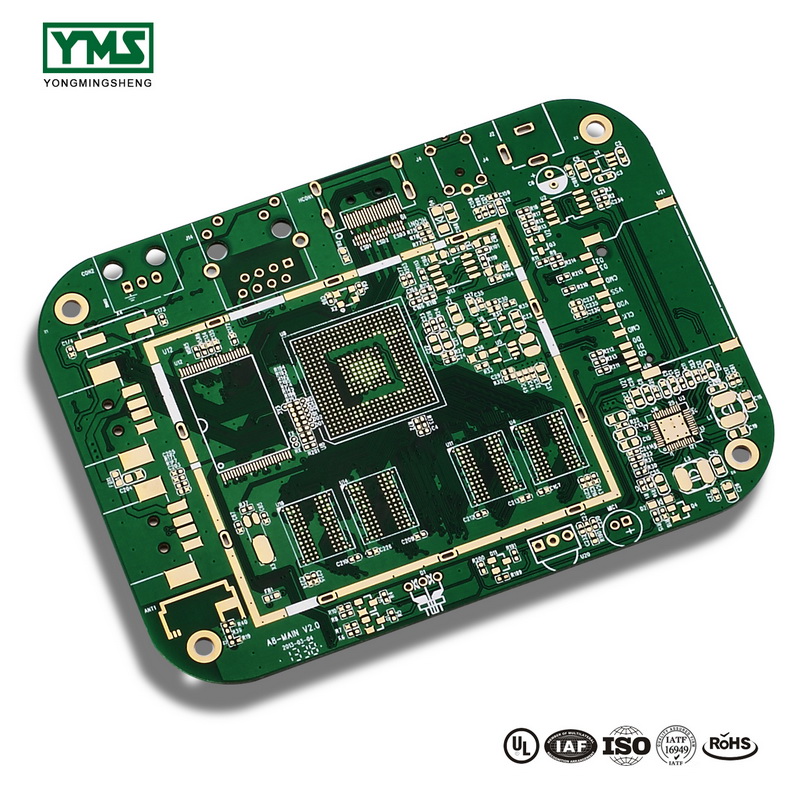

Funda ngakumbi malunga neemveliso zeYMS

Ixesha lokuposa: Apr-08-2022