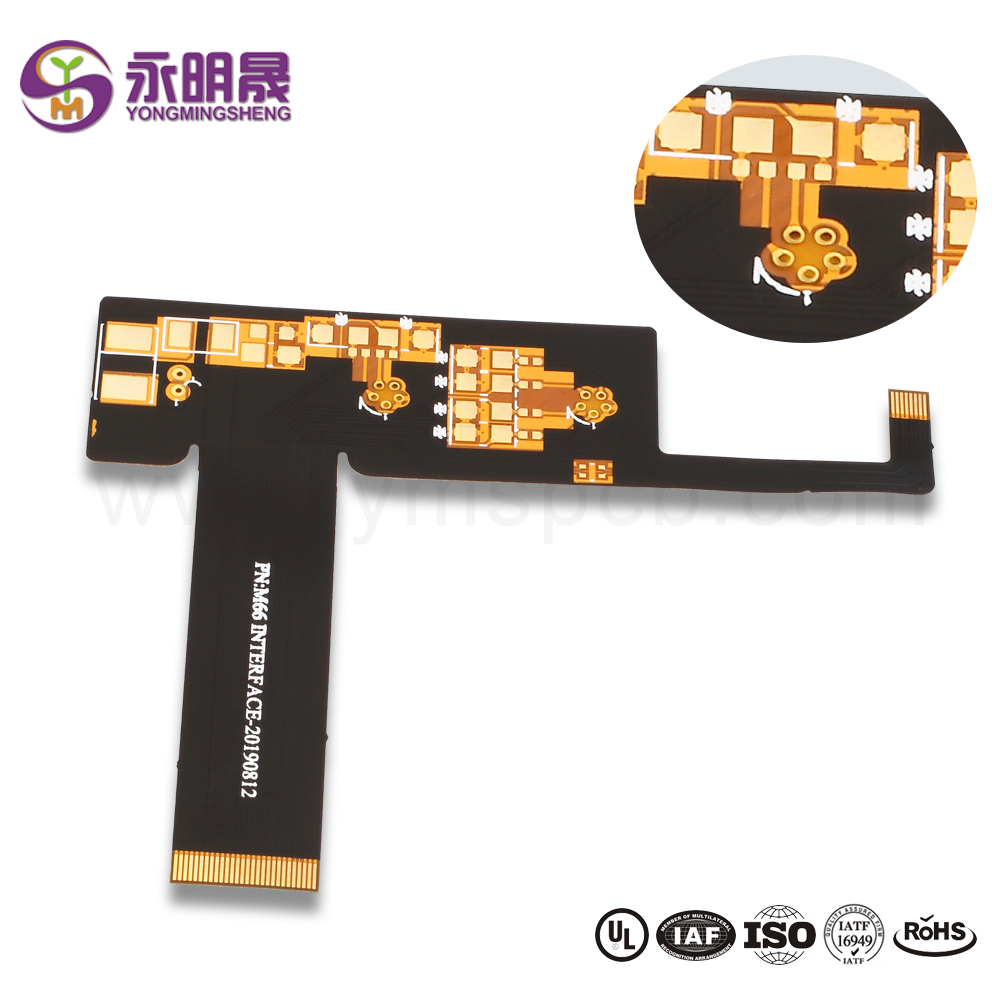

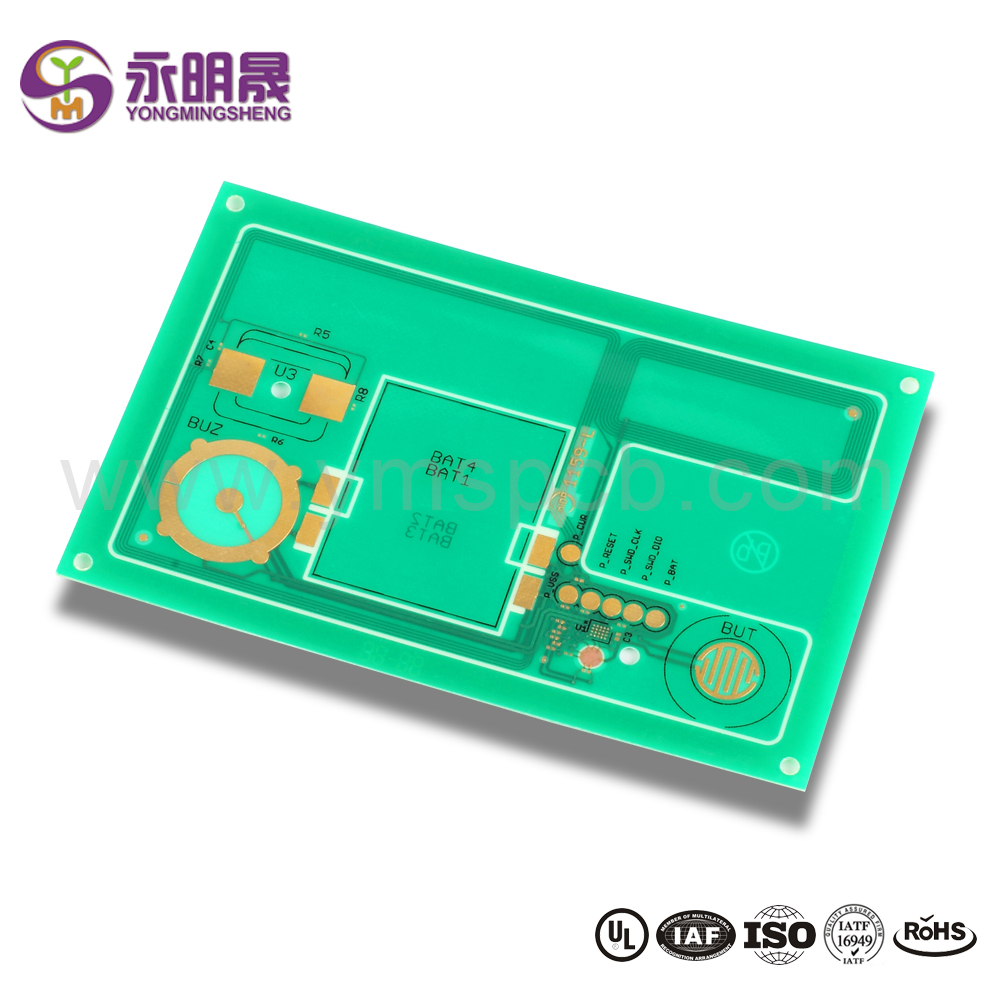

The flexible circuit board FPC board is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film as the base material. Referred to as soft board or FPC, it has the characteristics of high wiring density, lightweight, and thin thickness.

Overview of FPC flex board products

FPC flex board is a basic product in the electronics industry, widely used in electronic products such as communication equipment, computers, automotive electronics and industrial equipment and various household appliances. Its main function is to support circuit components and interconnect circuit components. FPC soft board is a large category of printed circuit boards. According to the structure of FPC flexible printed circuit boards, FPC manufacturers can be divided into single-sided, double-sided and multi-layer boards according to the number of conductor layers.

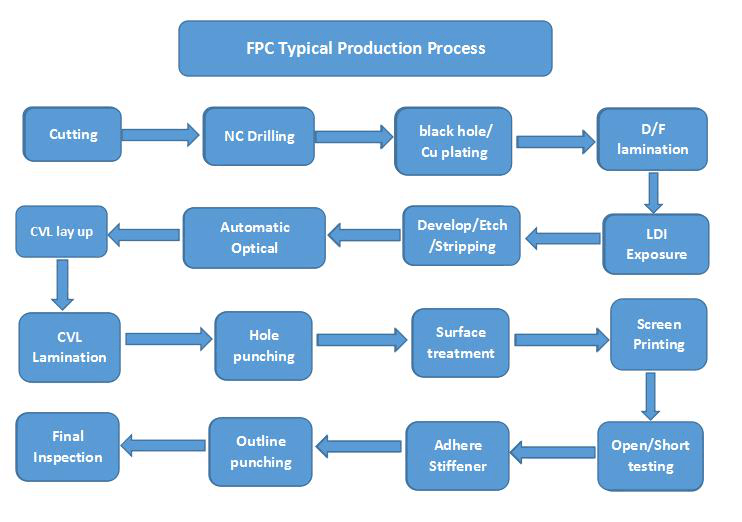

FPC production process

Single-sided FPC:

Single-sided copper clad laminate → Cut Lamination → washing, drying → drilling or punching → screen printing line anti-etching pattern or using dry film → solidify inspection and repairing → etching copper → etching resist ink, drying → washing, drying →solder mask, UV curing → screen printing, UV curing → preheating, punching and Form → open short circuit test → washing, drying → pre-coated soldering anti-oxidant (dry) or spray hot air flattening → inspection packaging → finished product delivery.

Double-sided FPC:

Double-sided copper clad laminate → Cut Lamination → lamination → CNC drilling →inspection, burr cleaning → PTH → full plate electroplated thin copper → inspection,washing → screen negative Circuit pattern, curing (dry film or wet film, exposure, developing) → inspection, repairing → line pattern plating → electroplating tin (resistance nickel/gold) → resist ink(photosensitive film) → → etching copper → (DE-WETTING) → Clean → solder mask(adhesive dry film or wet film, exposure, development, heat curing) → cleaning, drying → screen printing, curing → (HASL) → Profile → cleaning, drying → open short circuit test → inspection packaging → finished product delivery.

FPC flex board processing processSheet-by-sheet processing:

Sheet by Sheet, similar to a rigid board, is processed in an intermittent and step-by-step manner. FPC flexible board adopts the same process and similar equipment conditions as rigid board. In the form of processing, there are sheet-by-sheet processing: Sheet by Sheet, which is similar to a rigid board, which is intermittently processed one by one in a step-by-step manner, or Roll to Roll, which is a continuous processing of a roll of substrates. The above is the production process knowledge of FPC soft board of the soft board manufacturer, and it is still necessary to strictly control each process in the production process.

Learn more about YMS products

Post time: Apr-15-2022