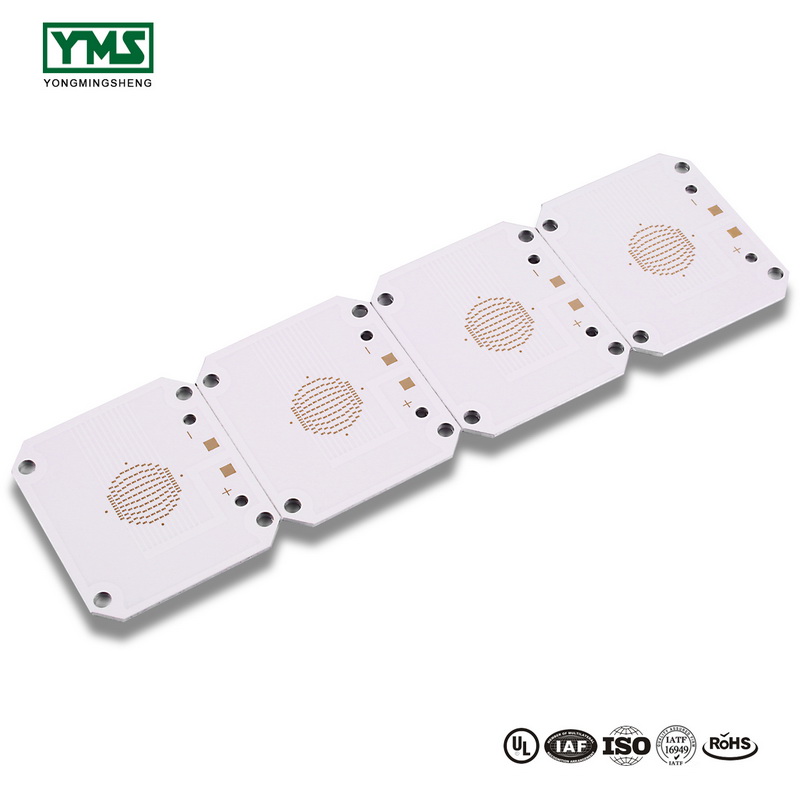

Aluminum base board is a kind of metal clad copper plate with good heat dissipation function. Generally, a single panel is composed of three layers, which are circuit layer (copper foil), insulation layer and metal base layer.

For high-end use are also designed as double panels, the structure of the circuit layer, insulation layer, aluminum or copper base, insulation layer, circuit layer.Very few applications are multilayer boards, which can be made by mixing common multilayer boards with insulation layers, aluminum or copper base.

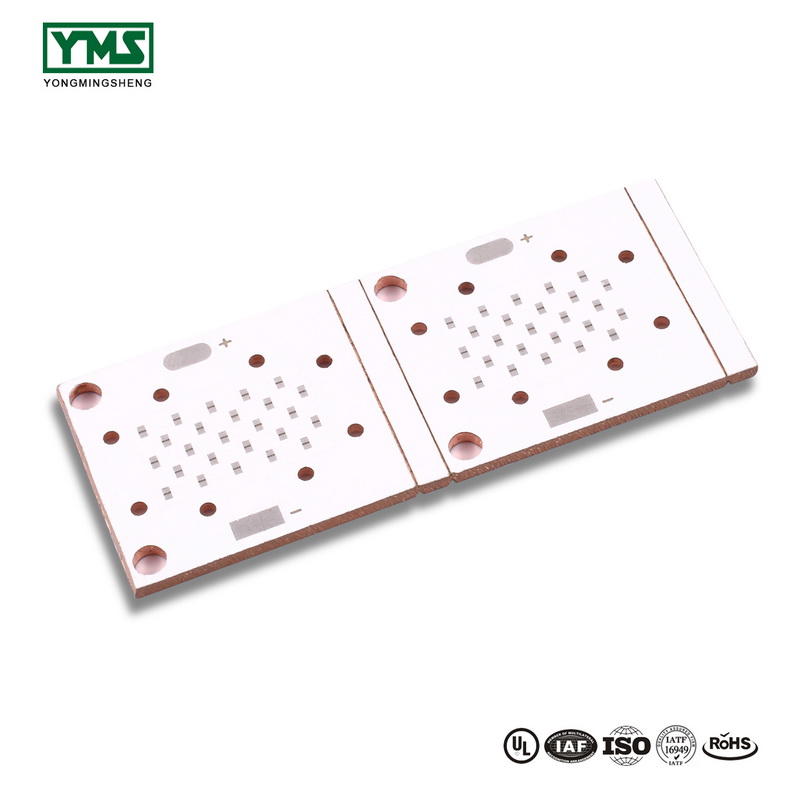

LED aluminum base board is PCB, is also the meaning of printed circuit board, just PCB material is aluminium alloy, we used the general circuit board material is glass fiber, but because the LED heat is larger, so the LED lamps and lanterns with the circuit board is commonly aluminum plate, or copper base board can be fast heat conduction, other equipment or electrical circuit board or glass fiber board!

The working principle of

The surface of the power device is mounted on the circuit layer, and the heat generated during the operation of the device is rapidly transmitted to the metal base layer through the insulation layer, and then the metal base layer transfers the heat out, so as to realize the heat dissipation of the device.

Compared with the traditional fr-4, aluminum base board or copper base board can minimize the thermal resistance, so that aluminum base board has excellent thermal conductivity.Compared with the thick film ceramic circuit, its mechanical properties are excellent.

In addition, aluminum base board, copper base board has the following unique advantages:

Ø meet RoHs requirements;

Ø more adapted to the SMT process;

Ø in circuit design scheme of thermal diffusion is extremely effective processing, to reduce the temperature of module operation, prolong service life, improve the power density and reliability;

Ø reduce the radiator and other hardware, including thermal interface materials, assembly, reduce the size of our products, reduce the hardware cost and assembly;

Ø will power circuit and control circuit optimization combination;

Ø instead of brittle ceramic substrates, better mechanical endurance.

Constitute a

Circuit layer

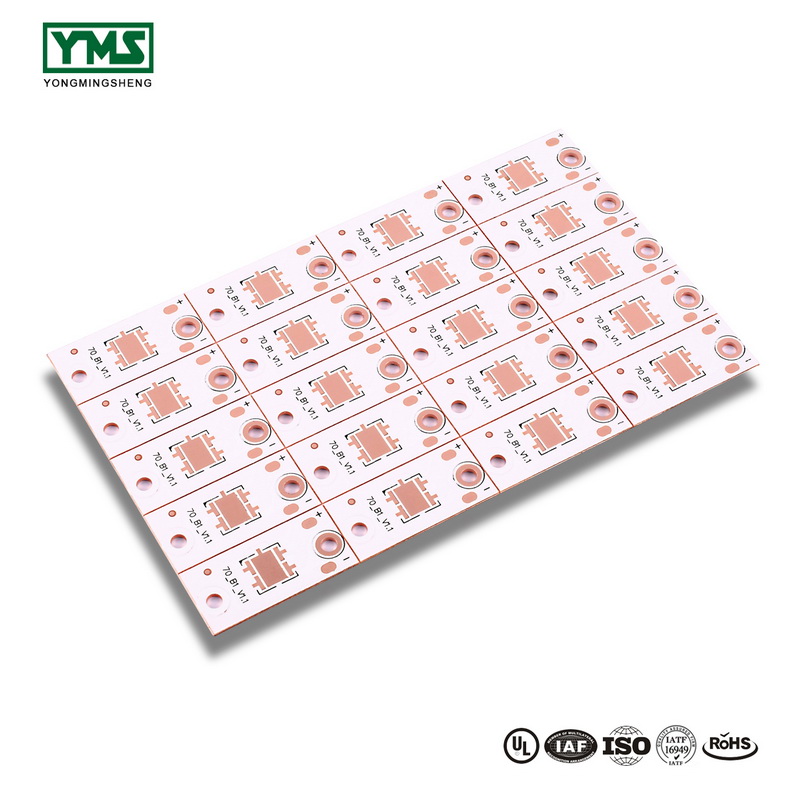

The circuit layer (usually electrolytic copper foil) is etched to form a printed circuit, which is used to realize the assembly and connection of devices.

Compared with traditional fr-4, aluminum base board can carry higher current with the same thickness and line width.

Insulating layer

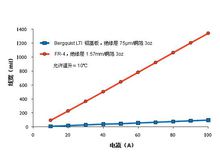

Insulation layer is the core technology of aluminum base board, which mainly plays the functions of bonding, insulation and heat conduction. Aluminum base board insulation layer is the largest thermal conductivity barrier in power module structure.

The better the heat conduction performance of the insulation layer is, the more conducive it is to the diffusion of heat generated during the operation of the device, and the more conducive it is to reducing the operating temperature of the device, so as to increase the power load of the module, reduce the volume, prolong the life and increase the power output.

FIG. 5 is a typical motor controller module. The figure on the right adopts traditional process (fr-4) and uses a large number of radiators, thermal interface materials and other accessories.

On the left side, because the aluminum base board with high thermal conductivity is adopted, a highly automated surface sticker product is obtained. The number of components in the whole product is reduced from 130 to 18, the power load is increased by 30%, and the module volume is greatly reduced.

Only aluminum base board with high thermal conductivity are suitable for such high-power density modules.

The metal base

The type of metal used for insulating metal substrate depends on the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface condition and cost of the substrate.

In general, from the cost and technical performance and other conditions to consider, aluminum plate is the ideal choice.The available aluminum plates are 6061,5052,1060, etc.

Copper plate, stainless steel plate, iron plate and silicon steel plate can also be used if higher thermal conductivity, mechanical properties, electrical properties and other special properties are required.

Features:

Metal base heat dissipation plate: including aluminum base board, copper base board, iron base plate;It is a low-alloyed al-mg-si alloy plate with high plasticity (see the structure below), which has good thermal conductivity, electrical insulation performance and mechanical processing performance.

Compared with the traditional fr-4, the aluminum base board adopts the same thickness and line width, and the aluminum base board can carry higher current. The aluminum base board can withstand voltage up to 4500V, and the thermal conductivity is greater than 2.0. In the industry, aluminum base board is the main part, and copper base board has strong heat dissipation energy, which is mainly used for high-power products.

● surface mount technology (SMT);

● heat diffusion is treated effectively in circuit design scheme;

● reduce product operating temperature, improve product power density and reliability, extend product life;

● reduce product volume, reduce hardware and assembly costs;

● replace fragile ceramic substrate for better mechanical endurance.structure

Aluminum base copper clad plate is a metal circuit board material, composed of copper foil, thermal insulation layer and metal substrate, its structure is divided into three layers:

Line layer: equivalent to common PCB copper-clad plate, line copper foil thickness 1oz to 10oz.

Insulation layer: insulation layer is a layer of low thermal resistance thermal insulation material.Thickness: 0.003 "to 0.006" "is the core technology of aluminum-based copper cladding, which has been UL certified.

BaseLayer base: it is a metal substrate, usually aluminum or optionally copper.Aluminum - based copper and traditional epoxy glass cloth laminate, etc.

PCB material has incomparable advantages compared with other materials.Suitable for SMT surface mount of power components.

Without radiator, the volume is greatly reduced, heat dissipation effect is excellent, good insulation and mechanical performance.

You May Like:

Post time: Aug-31-2019