Njengamanje, kunezinhlobo ezimbili ze- PCB ibhodi edge design: i-metallization kanye ne-non-metallization. Ngokungagcini i-metallization, abakhiqizi embonini sebekhulile, kodwa ubuchwepheshe be-metallization abukavuthwa. Namuhla, izidingo zokukhiqiza zamakhasimende amaningi ziphendukela ku- PCB metal edging . Ngakho-ke, izinga PCB metal edging isibe okugxilwe ukunakwa amakhasimende 'nabakhiqizi' ngoba izinga layo kuthinta ngqo ukusetshenziswa kwemikhiqizo.

Yiziphi izinhlelo zokusebenza ze-edge plating ku-PCB?

Amabhodi esekethe e-Edge avamile ezimbonini eziningi, futhi ukufakwa komphetho kuwumkhuba ovamile. Uzothola i-PCB edge castellation (noma ama-PCB acwecwe onqenqemeni) asetshenziswa ezimweni eziningi, okuhlanganisa:

· Ukuthuthukisa amakhono okuthwala amanje

· Izixhumanisi zomphetho nokuvikelwa

· I-Edge soldering ukuthuthukisa ukwenziwa

· Ukusekelwa okungcono kokuxhuma okufana namabhodi ashibilika kumakesi ensimbi

Iyini inqubo ye-PCB edge plating?

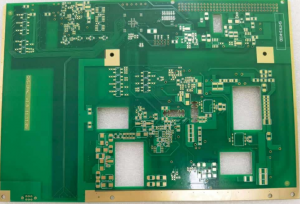

Njengoba wazi, kunezinselelo eziningi zomkhiqizi we-PCB ye-multilayer ikakhulukazi endleleni yokulungisa imiphetho egcwele kanye nokunamathela kwesikhathi sokuphila kwento ehlanganisiwe, ngaphezu kwalokho, idinga ukuphathwa okunembayo ekukhiqizeni kwe-PCB okusetshenziselwa unqenqema. PCB soldering. Singaqinisekisa ukuthi i-PCB edge castellation ilungiselela kahle izindawo ezingaphezulu, ezisebenzisa ithusi elicwecwe ukuze linamathele ngokushesha futhi licubungule ibhodi lesifunda ukuze kuqinisekiswe ukunamathela kwesikhathi eside phakathi kongqimba ngalunye.

Akudingekile ukusho ukuthi, singakwazi ukulawula ubungozi obungaba khona bokwembozwa ngembobo nasemaphethelweni ngenqubo elawulwayo ngesikhathi sokwenziwa kwebhodi lesifunda eliphrintiwe ukuze kufakwe i-edge soldering. Ngakho-ke ukukhathazeka okubaluleke kakhulu ukwakhiwa kwama-burrs, okuholela ekunqanyulweni kokunamathiselwe ngezindonga zembobo futhi kukhawule impilo yokunamathela konqenqema lokucwenga.

Amakhontolo angaphandle, azokwenziwa ngensimbi, kufanele agaywe ngaphambi kwenqubo yokucwenga emgodini, njengoba ukufakwa kwensimbi emaphethelweni kwenzeka phakathi nalesi sinyathelo sokwenziwa. Ngemuva kokufakwa kwethusi, ukuqedwa kwendawo okuhlosiwe ekugcineni kusetshenziswe emaphethelweni.

Izinkinga Zokwenziwa:

1. I-Copper Peeling -Ukufaka phezu kwendawo enkulu ye-substrate kungaholela ekucwecweni kwethusi okucwecwe ngenxa yokuntuleka kwamandla okunamathela. Lokhu sibhekana nakho ngokuqala ngokulungisa ingaphezulu ngokusebenzisa inhlanganisela yamakhemikhali nezinye izindlela zobunikazi. Okulandelayo, sisebenzisa i-metalization eqondile, enamandla amakhulu ebhondi yethusi, ukuze kulungiswe indawo engaphezulu ukuze icwecwe.

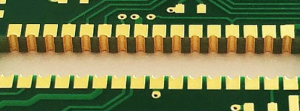

2. Ama-Burrs -Imvamisa ukucwenga onqenqemeni, ikakhulukazi ezimbotsheni ze-castellation, kungabangela ama-burrs kusukela kunqubo yokugcina yokwenza. Sisebenzisa ukugeleza kwenqubo eshintshiwe, yobunikazi eholela ekutheni ama-burrs aphuculwe aze afike ekugcineni kwesici.

Inothi le-Fab:

1. Indawo ye-antenna yephedi yegolide inkulu kakhulu, ithinta ukuthelwa kwekhasimende noma ukudluliswa kwesignali.

2. Iphedi yonqenqema lwangaphakathi ixhunywe ezintanjeni ebhodini, okuholela kumjikelezo omfushane.

3. Imbobo yesitembu yakhelwe endaweni engenela futhi kufanele isingathwe kunqubo yesibili yokumba.

4. Ngokwakhiwa okuhlobene nenqubo kwama-PCB angawodwana njengephaneli, ukufakwa kwensimbi okuqhubekayo kwemiphetho yangaphandle akunakwenzeka. Ayikho i-metallization engasetshenziswa lapho amabhuloho amaphaneli amancane atholakala.

5. Isicelo esisodwa, i-metallization ye-slide plating ingambozwa nge-solder mask.

Lapho uthenga amabhodi okunamathisela onqenqemeni, kufanele uqinisekise nomphakeli wakho we-PCB ukuthi kungenzeka yini ukukhiqiza ama-PCB ngenqubo yokucwenga, kanye nezinga umkhiqizi angaphetha ngalo ipuleti le-PCB. Amafayela akho e-Gerber noma umdwebo we-fab kufanele ubonise ungqimba oluwumshini lapho adinga khona ukupulalwa kwama-slide, kanye nokuqeda okungaphezulu akudingayo kuwo. Abakhiqizi abaningi bakhetha i-ENIG ekhethiwe njengokuwukuphela kwendawo yokuqeda efanele i-castellation eyindilinga.

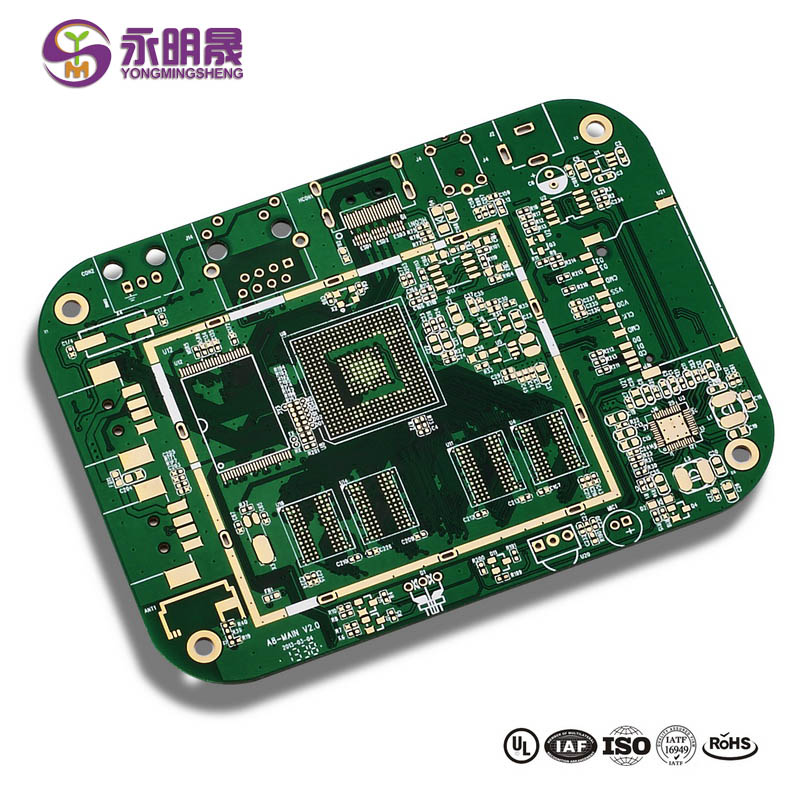

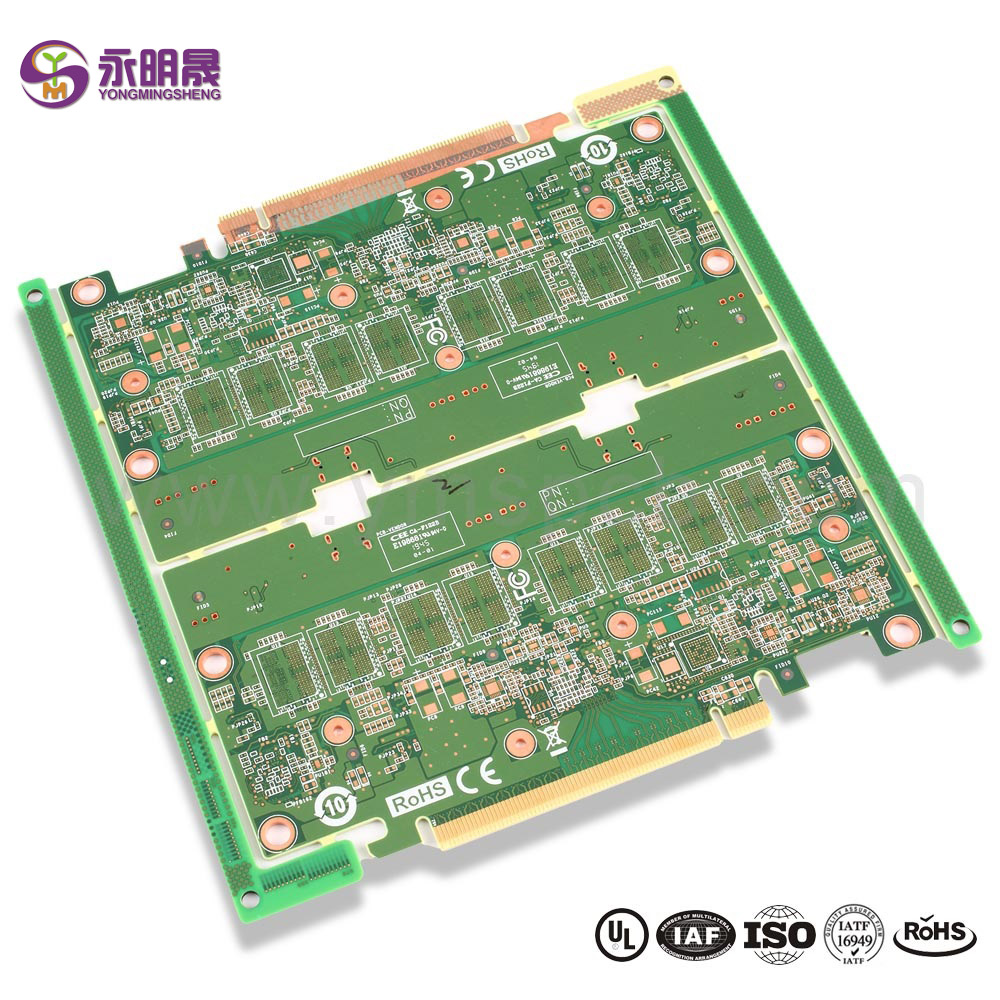

I-YMS Electronics Co., Ltd. ingumkhiqizi ochwepheshile wamabhodi wesekethe we-multilayer anembe kakhulu, amabhodi wemojuli wokucwiliswa kwegolide, amabhodi esifunda sezimoto, amarekhodi okushayela, izinto zikagesi ze-COB, amabhodi womama wekhompyutha, amabhodi esekethe yezokwelapha, amabhodi emojula ebhondi, i-blind hole impedance. ibhodi, i-thermoelectric separation yethusi substrate, njll. I-RayMing inikeza isiqinisekiso sekhwalithi ephezulu kanye nokulethwa kwesikhathi, ibhizinisi lobuchwepheshe obuphezulu elithengisa lilonke. Uma kunesidingo samabhodi egolide anamacele, sicela ukhululeke ukuxhumana nathi!

Funda kabanzi ngemikhiqizo ye-YMS

Isikhathi sokuthumela: Apr-07-2022