Printed Circuit Board (PCB) is a kind of Printed Circuit Board, which is widely used in various electronic and related products.

PCB, also known as PWB (Printed Wire Board), was once used more in Hong Kong and Japan, but is now less common (actually, PCB and PWB are different).

In western countries and regions, it is generally called PCB; in the east, it is called PCB because of different countries and regions. For example, in China, it is commonly called printed circuit board (formerly called printed circuit board); in Taiwan, it is commonly called PCB; in Japan, it is called electronic (circuit) substrate; in Korea, it is called substrate.

PCB is the support body of electronic components and the carrier of electrical connection of electronic components, which mainly plays the role of support and interconnection.

Pure from the outside, the circuit board outer layer mainly has three colors: gold, silver, light red.

Categorize by price: gold is the most expensive, silver is the second most expensive, and light red is the cheapest. But the circuit board inside is mostly pure copper, or bare copper.

The PCB is said to contain many precious metals. The average smartphone contains 0.05g of gold, 0.26g of silver and 12.6g of copper.

Why is there precious metal on PCB?

PCB as the support body of electronic components, its surface needs to be welded, so a part of copper layer is required to be exposed for welding.

These exposed layers of copper are called pads, which are usually rectangular or round and are very small, so the only thing left exposed to the air is the pad.

PCB exposed pad, copper layer directly exposed.This part needs to be protected from oxidation

The copper used in PCB is easily oxidized. If the copper on the welding pad is oxidized, it will not only be difficult to weld, but also increase the resistivity, which will seriously affect the performance of the final product.

Therefore, the welding pad is plated with inert metal gold, or the surface is covered with silver by chemical process, or the copper layer is covered with a special chemical film to prevent the contact between the welding pad and the air. Prevent oxidation and protect pad to ensure good yield in subsequent welding process.

Gold, silver and copper on PCB

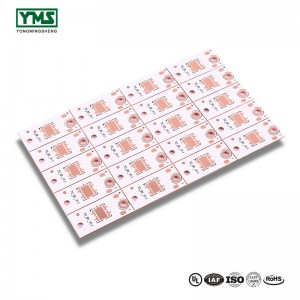

1. Copper clad PCB

Copper-clad plate is a kind of plate-like material made by soaking glass fiber cloth or other reinforcing material with resin and covering copper foil on one side or on both sides through hot pressing.

Take glass fiber brass-clad copper clad plate as an example, its main raw materials are copper foil, glass fiber cloth, epoxy resin, accounting for about 32%, 29% and 26% of the product cost respectively.

Copper clad board is the basic material of printed circuit board and printed circuit board is the indispensable main component of most electronic products to achieve circuit interconnection. With the continuous improvement of technology level, some special electronic copper clad board can be used to directly manufacture printed electronic components in recent years.

The conductor used in printed circuit boards is generally made of thin foil of refined copper, that is, copper foil in a narrow sense.

2. PCB embedded gold circuit board

The direct contact between gold and copper will have the physical reaction of electron migration and diffusion (the relationship of potential difference), so we must first electroplate a layer of "nickel" as a barrier layer, and then electroplate the gold to the nickel, so we commonly called electroplating, its actual name should be called "electroplating nickel gold".

The difference between hard gold and soft gold is the composition of the last layer of gold plated, gold plating can choose pure gold or alloy, because the hardness of pure gold is relatively soft, so it is called "soft gold".

Since "gold" can form a good alloy with "aluminum", the thickness of this pure gold layer is specially required by COB when making aluminum wire.

In addition, if you choose electroplated nickel-alloy or gold-cobalt alloy, the alloy will be harder than pure gold, so it is called "hard gold".

Gold-plated layer is widely used in the position of circuit board components welding pad, gold finger, connector shrapnel and so on.The most widely used cell phone circuit boards are mostly gold-plated, gold-plated, computer motherboards, audio and small digital circuit boards are generally not gold-plated.

Gold is real gold. Even a very thin coating accounts for nearly 10% of the cost of a circuit board. The use of gold as a coating, one is to facilitate welding, two is to prevent corrosion.

Even the gold board of several years' worth of memory sticks still sparkle, and when copper, aluminum, and iron are used, they soon rust into scrap.

In addition, the cost of gold plate is high, and the welding strength is poor, because the use of nickel plating process, easy to have the problem of black plate. The nickel layer oxidizes over time, and long-term reliability is a problem.

3. PCB silver PCB

Silver deposit is cheaper than gold deposit. If PCB has connection function requirement and need to reduce cost, silver deposit is a good choice.In addition to the good flatness and contact of silver settling, the silver settling process should be chosen.

It is widely used in communication products, automobile and computer peripherals, and in high-speed signal design.

Because of its excellent electrical properties that no other surface treatment can match, it can also be used in high frequency signals.Silver precipitation process is because it is easy to assemble and has good inspection. But silver deposits grow slowly (but not slowly) due to defects such as tarnishing and voids in solder joints.

Expand

As the connection carrier of integrated electronic components, PCB quality will directly affect the performance of intelligent electronic equipment. Among them, the quality of printed circuit board electroplating is particularly important.

Electroplating can improve circuit board protection, weldability, conductivity and wear resistance.

Electroplating is an important step in the manufacturing process of printed circuit board. The quality of electroplating is related to the success of the whole process and the performance of the circuit board.

PCB's main electroplating processes are copper, tin, nickel, gold plating and so on.

Electroplating copper is the basic coating of circuit board electrical interconnection.

As an anticorrosive layer in graphics processing, electroplating tin is a necessary condition for making high precision circuits.

Nickel plating is to electroplate a layer of nickel barrier layer on the circuit board to prevent the mutual dialysis between copper and gold.

Electroplating can prevent nickel surface passivation, so as to meet the circuit board welding, corrosion resistance and other properties.

You May Like:

Post time: Sep-07-2019