Factory Outlets Hi-Pot Withstand Copper Base Pcb - High speed PCB POFV insertion loss test enepig| YMSPCB – Yongmingsheng

Factory Outlets Hi-Pot Withstand Copper Base Pcb - High speed PCB POFV insertion loss test enepig| YMSPCB – Yongmingsheng Detail:

What is a High Speed PCB?

“High Speed” is generally interpreted to mean circuits where the length of the signal’s rising or falling edge is greater than about one-sixth of the transmission line length greater then the transmission line length, then the transmission line length demonstrates lumped line behavior.

In a high speed PCB, the rise time is fast enough that the bandwidth for the digital signal can extend into the high MHz or GHz frequencies. When this happens, there are certain signalling problems that will be noticed if a board is not designed using high speed PCB design rules. In particular, one might notice:

1. Unacceptably large transient ringing. This generally occurs when traces are not wide enough, although you need to be careful when making your traces wider (see the section on Impedance Contorl in PCB Design below). If transient ringing is quite large, you’ll have large overshoot or undershoot in your signal transitions.

2.Strong crosstalk. As the signal speed increases (i.e., as the rise time decreases), capacitive crosstalk can become quite large as the induced current experiences capacitive impedance.

3.Reflections off of driver and receiver components. Your signals can reflect off of other components whenever there is an impedance mismatch. Whether or not the impedance mismatch becomes important requires looking at the input impedance, load impedance, and transmission line characteristic impedance for an interconnect. You can read more about this in the following section.

4.Power integrity problems (transient PDN ripple, ground bounce, etc.). This is another set of unavoidable problems in any design. However, transient PDN ripple and any resulting EMI can be reduced significantly through proper stackup design and decoupling measures. You can read more about high speed PCB stackup design later in this guide.

5.Strong conducted and radiated EMI. The study of solving EMI problems is extensive, both at the IC level and the high speed PCB design level. EMI is essentially a reciprocal process; if you design your board to have strong EMI immunity, then it will emit less EMI. Again, most of this boils down to designing the right PCB stackup.

| YMS High Speed PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-30L | |

| Available High Speed PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Mixed Dielectric Boards (High Speed Material+FR-4 combinations ) | ||

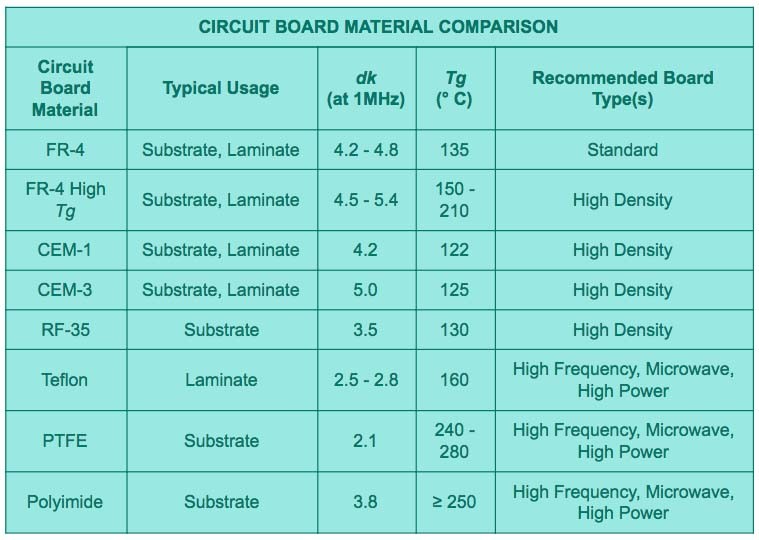

| Suitable High Speed Materials available : M4,M6 series,N4000-13 series, FR408HR,TU862HFTU872SLKSP, EM828,etc. | ||

| Tight Etch Tolerances on Critical RF Features:+/- .0005″ standard tolerance for unplated 0.5oz copper | ||

| Multilevel cavity constructions, Copper coins and slugs, Metal Core & Metal Back, Thermally conductive laminates,Edge Plating, etc. | ||

| Thickness | 0.3mm-8mm | |

| Minimum line Width and Space | 0.075mm/0.075mm(3mil/3mil) | |

| BGA PITCH | 0.35mm | |

| Min laser Drilled Size | 0.075mm(3nil) | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for laser hole | 0.9:1 | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | Suitable High Speed PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Laser via copper plated shut | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

Product detail pictures:

Related Product Guide:

Global HDI Market 2019 – Unimicron, Compeq, AT&S, SEMCO, Ibiden, TTM, ZDT, Tripod, DAP | Hdi Pcb

HDI PCBs Market Booming Trends 2019-2024: Ibiden Group, NCAB Group, Bittele Electronics, TTM Technologies | 1.2m 2layer Led Pcb

We stay with our company spirit of "Quality, Performance, Innovation and Integrity". We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Factory Outlets Hi-Pot Withstand Copper Base Pcb - High speed PCB POFV insertion loss test enepig| YMSPCB – Yongmingsheng , The product will supply to all over the world, such as: Karachi, America, Latvia, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, comprehensive meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.