Factory wholesale Resin Plug Hole Hdi Pcb - 10 Layer High Tg Hard Gold HDI Board | YMS PCB – Yongmingsheng

Factory wholesale Resin Plug Hole Hdi Pcb - 10 Layer High Tg Hard Gold HDI Board | YMS PCB – Yongmingsheng Detail:

The substrate of High Tg circuit board will change from “glass state” to “rubber state” when the temperature rises to a certain area, and this temperature is called the glass transition temperature (Tg) of the board. In other words, Tg is the maximum temperature (℃) at which the substrate remains rigid. That is to say, ordinary PCB substrate materials at high temperature not only produce softening, deformation, melting and other phenomena, but also performance in the mechanical, electrical characteristics of a sharp decline (I don’t think we want to see their products appear this situation).

Generally speaking, the board of Tg is more than 130 degrees, high Tg is more than 170 degrees, and medium Tg is more than 150 degrees.

Usually Tg≥170℃ PCB, called high Tg PCB.

When the Tg of the substrate increases, the circuit board’s heat resistance, moisture resistance, chemical resistance, stability resistance and other characteristics will be improved. The higher the TG value, the better the temperature resistance of the plate. And the high TG is often applied in the lead-free process,

High Tg refers to high heat resistance. With the rapid development of the electronic industry and the electronic products represented by computer, the higher heat resistance of PCB substrate materials have become an important guarantee when the development towards into a high function and high multilayer. What’s more, the appearance and development of high-density installation technology represented by SMT and CMT make PCB more and more inseparable from the support of high heat resistance of substrate in small aperture, fine circuit and thin form.

Therefore, the difference between the general fr-4 and the high Tg fr-4 is that in the thermal state, especially in the case of heat after moisture absorption. And there are many differences in the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other conditions of the materials. The products with high Tg are obviously better than ordinary PCB substrate materials. In recent years, the number of customers requiring the production of high Tg circuit board increased year by year.

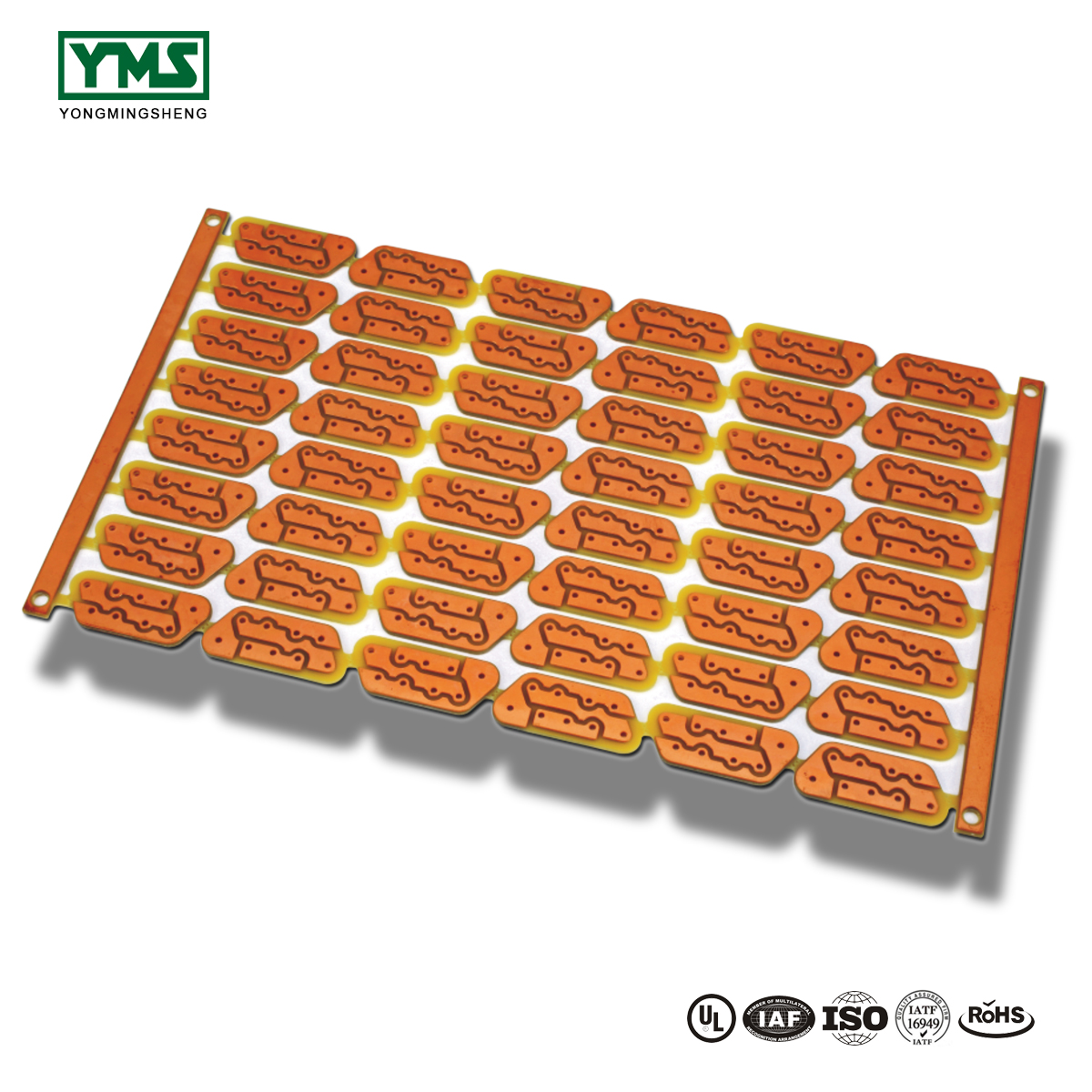

Product detail pictures:

Related Product Guide:

High-Density Interconnect (HDI) PCB Market Expected to Expand at a Steady CAGR through 2026 | Rigid-Flexible Pcb

LDI (Laser Direct Imaging) Machines Market Global Size, Demand-sales, Suppliers by Key Applications 2019 Detailed Analysis and Growth Aspects on Manufacturing Landscapes | Hdi Pcb

Our company insists all along the quality policy of "product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, shopper first" for Factory wholesale Resin Plug Hole Hdi Pcb - 10 Layer High Tg Hard Gold HDI Board | YMS PCB – Yongmingsheng , The product will supply to all over the world, such as: UK, Kyrgyzstan, Slovenia, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.