Tsarin Kera Aluminum PCB

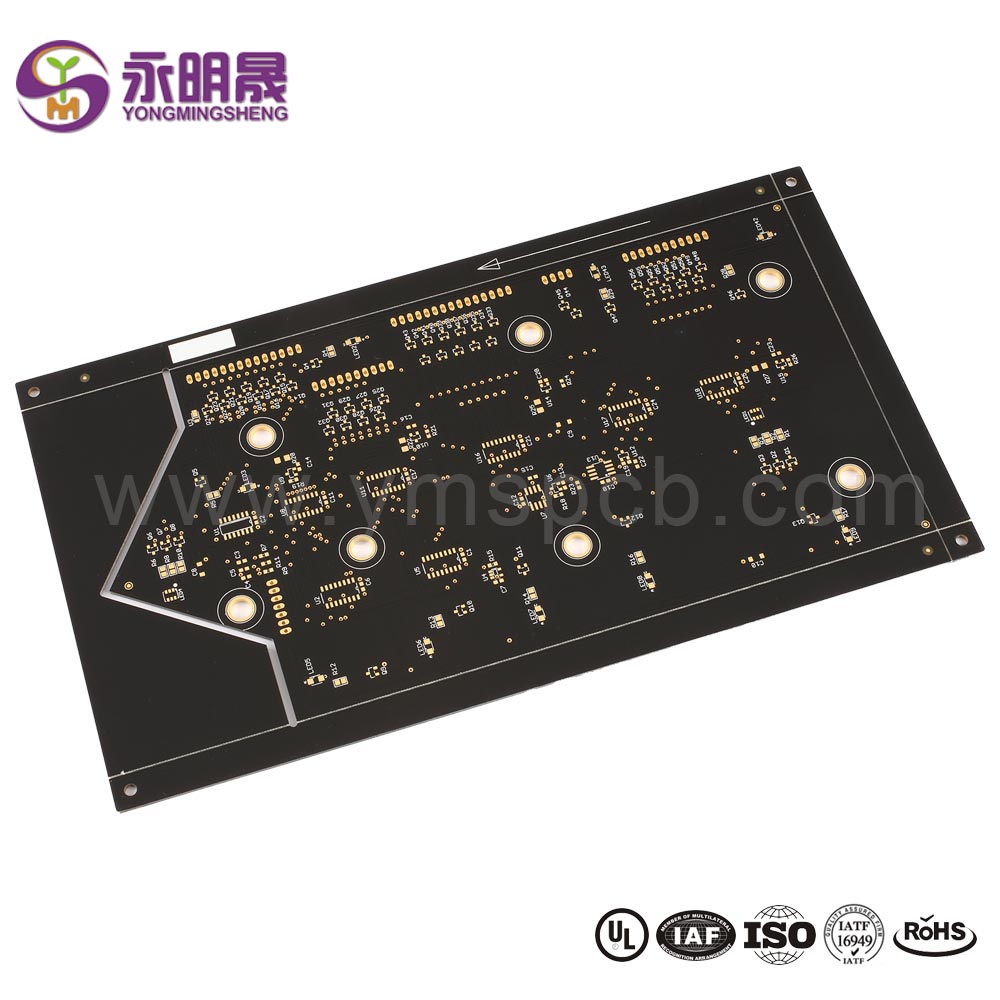

Aluminum PCB Manufacturing ProcessAluminum PCB masana'antu tsari na PCB tare da OSP surface gama: Yanke → Drilling → Circuit → Acid / alkaline etching → Solder Mask → Silkscreen → V-cut → PCB Test → OSP → FQC → FQA → Shirya → Bayarwa.

Tsarin masana'anta na PCB na aluminum tare da ƙare HASL: Yanke → Drilling → Circuit → Acid / alkaline etching → Solder Mask → Silkscreen → HASL → V-cut → Gwajin PCB → FQC → FQA → Shirya → Bayarwa.

YMSPCB iya samar da aluminum core PCB tare da wannan surface gama tsari kamar FR-4 PCB: Immersion Gold / bakin ciki / azurfa, OSP, da dai sauransu.

A cikin aiwatar da ƙera PCB na aluminium, ana ƙara ɗan ƙaramin dielectric na bakin ciki tsakanin madaurin da'ira da tushe mai tushe. Wannan Layer na dielectric duka biyun yana da insulating na lantarki, da kuma thermal conductive. Bayan ƙara dielectric Layer, da kewaye Layer ko jan karfe ne etched

Sanarwa

1. Saka allon a cikin keji-shelf ko raba su da takarda ko filastik zanen gado don kauce wa scratches a lokacin sufuri na dukan samar.

2. Yin amfani da wuka don ƙwanƙwasa rufin da aka keɓe a kowane tsari ba a yarda da shi ba yayin duk samarwa.

3. Don allunan da aka yi watsi da su, ba za a iya yin amfani da kayan tushe ba amma an yi musu alama kawai tare da "X" ta hanyar man fetur.

4. Jimlar duba ƙirar dole ne saboda babu wata hanyar magance matsalar ƙirar bayan etching.

5. Gudanar 100% IQC cak ga duk out-sourcing allon bisa ga ka'idojin kamfanin.

6. Tara duk allunan da ba su da lahani tare (kamar launi mai duhu & tarkace na saman AI) don sake sarrafa su.

7. Duk wani matsala a lokacin samarwa dole ne a sanar da ma'aikatan fasaha masu dangantaka a lokacin da za a warware.

8. Duk matakai dole ne a aiwatar da su sosai tare da bin buƙatu.

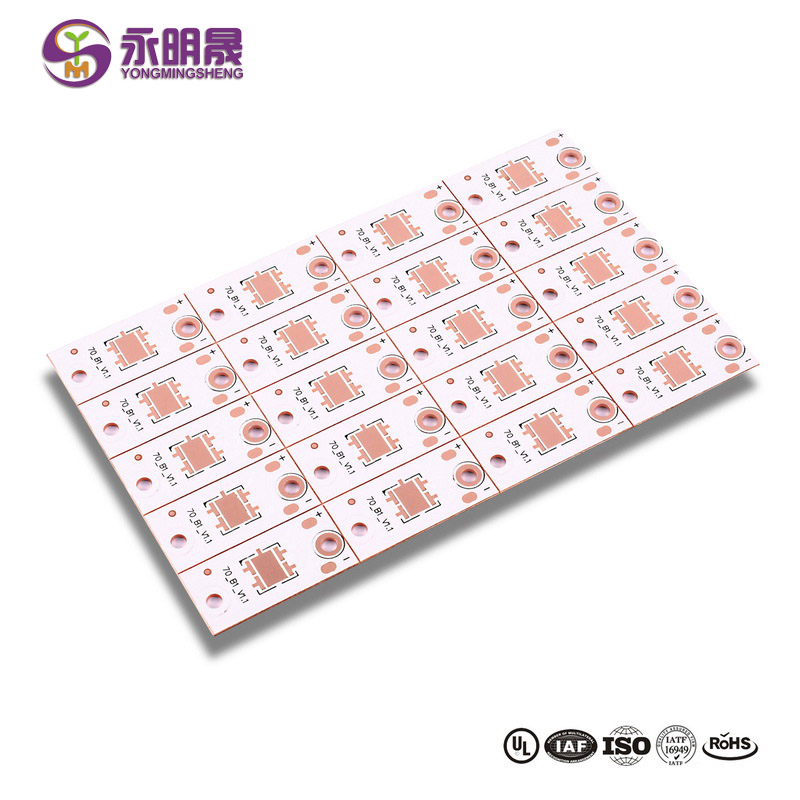

Allolin da'ira da aka buga kuma ana san su da PCBs na ƙarfe kuma sun ƙunshi laminates na ƙarfe da aka rufe da yaduddukan da'ira na tagulla. An yi su ne da faranti na allo waɗanda ke hade da aluminum, magnesium da silumin (Al-Mg-Si). Aluminum PCBs suna isar da ingantaccen rufin lantarki, kyakkyawan yuwuwar thermal da babban aikin injina, kuma sun bambanta da sauran PCBs ta hanyoyi masu mahimmanci.

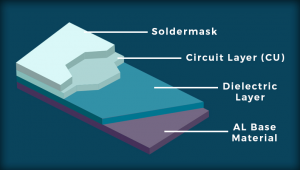

Aluminum PCB Layers

GASKIYAR TSARO

Wannan Layer ya ƙunshi abin da ake kira aluminum gami substrate. Amfani da aluminium ya sa irin wannan PCB ya zama kyakkyawan zaɓi don fasahar ramuka, wanda aka tattauna daga baya.

THERMAL INSULATION LAYER

Wannan Layer muhimmin abu ne mai mahimmanci na PCB. Ya ƙunshi polymer yumbu wanda ke da kyawawan kaddarorin viscoelastic, babban juriya na thermal kuma yana kare PCB daga matsalolin injina da zafi.

DAWAN DA'AWA

Layin kewayawa ya ƙunshi foil ɗin tagulla da aka ambata a baya. Gabaɗaya, masana'antun PCB suna amfani da foils na jan karfe daga oza ɗaya zuwa 10.

LAYIN DIELECTRIC

Dielectric Layer na rufi yana ɗaukar zafi yayin da halin yanzu ke gudana ta cikin da'irori. Ana canja wannan zuwa Layer na aluminum, inda zafi ya tarwatsa.

Samun mafi girman fitowar haske mai yiwuwa yana haifar da ƙarin zafi. PCBs tare da ingantattun juriya na zafi suna ƙara rayuwar ƙãre samfurin ku. Ƙwararriyar masana'anta za ta samar muku da ingantaccen kariya, rage zafi da amincin sashi. A YMS PCB, mun riƙe kanmu ga ingantattun ma'auni da ingancin ayyukan ku.

Ƙara koyo game da samfuran YMS

Mutane kuma suna tambaya

Lokacin aikawa: Janairu-20-2022