Habka Soo saarista Aluminium PCB

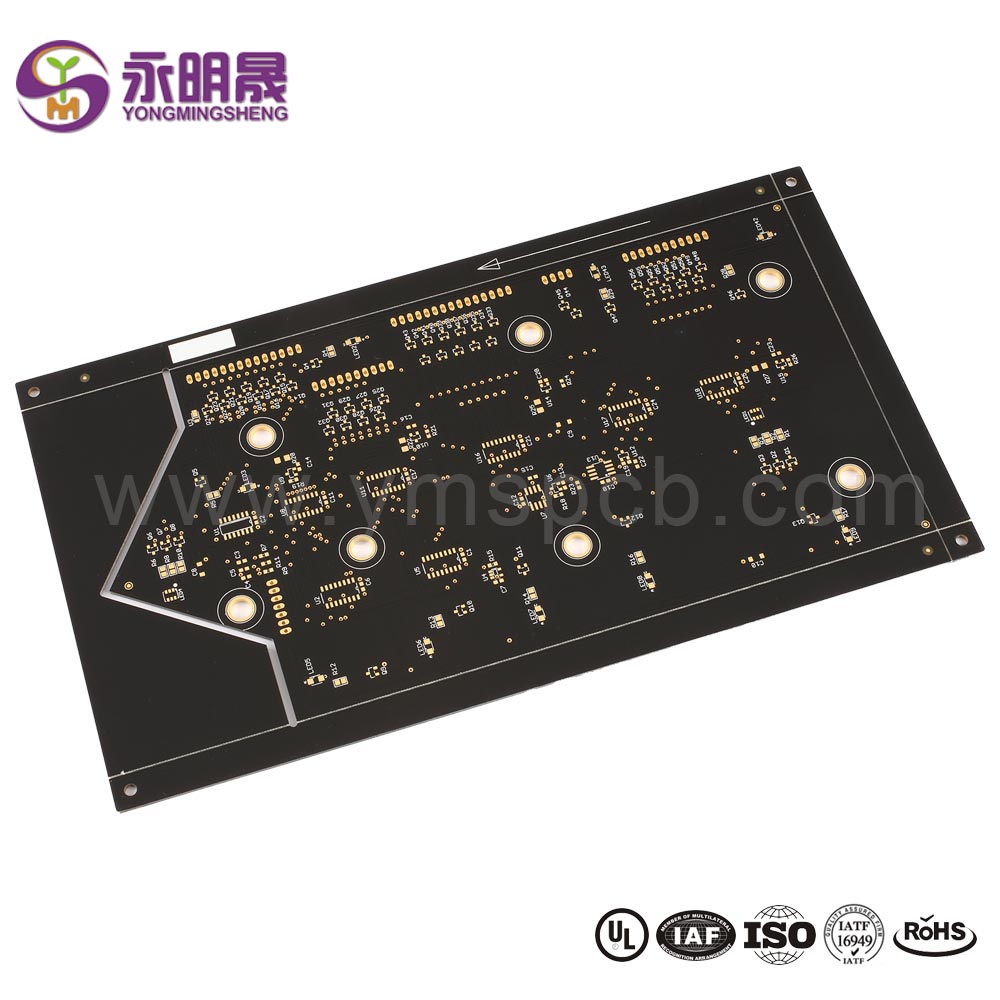

Nidaamka Wax soo saarka Aluminium PCB Habka wax soo saarka ee aluminium PCB oo leh dusha sare ee OSP: Goynta → Qodista → Wareegga → Acid / alkaline etching → Maaskarada Alxan → Silkscreen → V-cut → PCB Test → OSP → FQC → FQA → Baakad → Bixinta.

Habka wax soo saarka ee aluminium PCB oo leh HASL dusha sare: Goynta → Qodista → Wareegga → Acid / alkaline etching → Maaskarada alxanka → HASL → V-cut → Tijaabada PCB → FQC → FQA → Baakad → Bixinta.

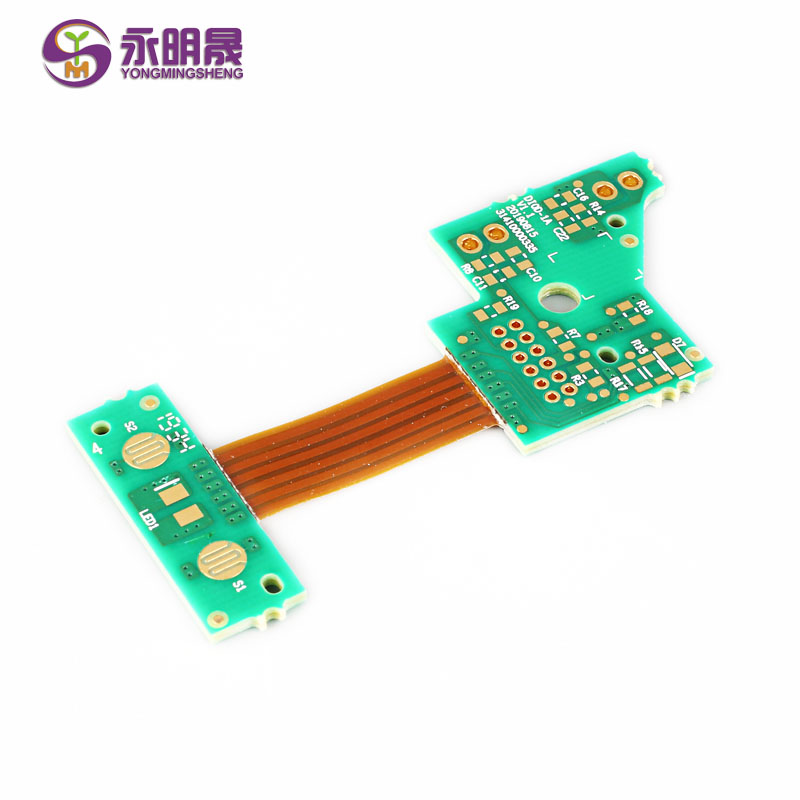

YMSPCB waxay ku siin kartaa PCB-ga aluminiumka udub-dhexaadka u ah habka dhammaystirka dusha sare ee FR-4 PCB: Immersion Gold / khafiif ah / qalin, OSP, iwm.

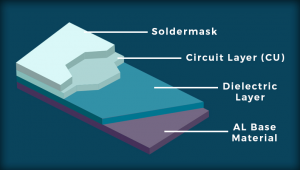

Habka soo saarista aluminium PCB, lakab khafiif ah oo dielectric ah ayaa lagu daraa inta u dhaxaysa lakabka wareegga iyo lakabka saldhigga. Lakabkan dielectric waa labadaba korantada, iyo sidoo kale kuleyl ahaan. Ka dib marka lagu daro lakabka dielectric, lakabka wareegga ama foornada naxaasta waa la xoqay

Ogaysiis

1. Ku rid looxyada khafis-qafiska ama ku kala saar warqad ama baco si aad uga fogaato xagashada inta lagu jiro gaadiidka dhammaan wax soo saarka.

2. Isticmaalka mindi si aad u xoqdo lakabka daboolan ee hab kasta lama ogola inta lagu jiro wax soo saarka oo dhan.

3. Looxyada la dayacay, walxaha saldhigga ah lama qodi karo laakiin waxaa kaliya oo lagu calaamadeeyay "X" qalin-saliid.

4. Wadarta guud ee kormeerka qaabka waa waajib sababtoo ah ma jirto si loo xalliyo dhibaatada qaabka ka dib marka la xoqo.

5. Samee 100% IQC hubinta dhammaan looxyada wax-soo-saarka leh si waafaqsan heerarka shirkadeena.

6. Isku soo wada ururi dhammaan looxyada cilladaysan (sida midab madow & xagashada dusha AI) si dib loo habeeyo.

7. Dhibaato kasta inta lagu jiro wax-soo-saarka waa in lagu wargeliyaa shaqaalaha farsamada ee la xidhiidha wakhtiga la xallinayo.

8. Dhammaan geeddi-socodyada waa in si adag loo maamulaa iyadoo la raacayo shuruudaha.

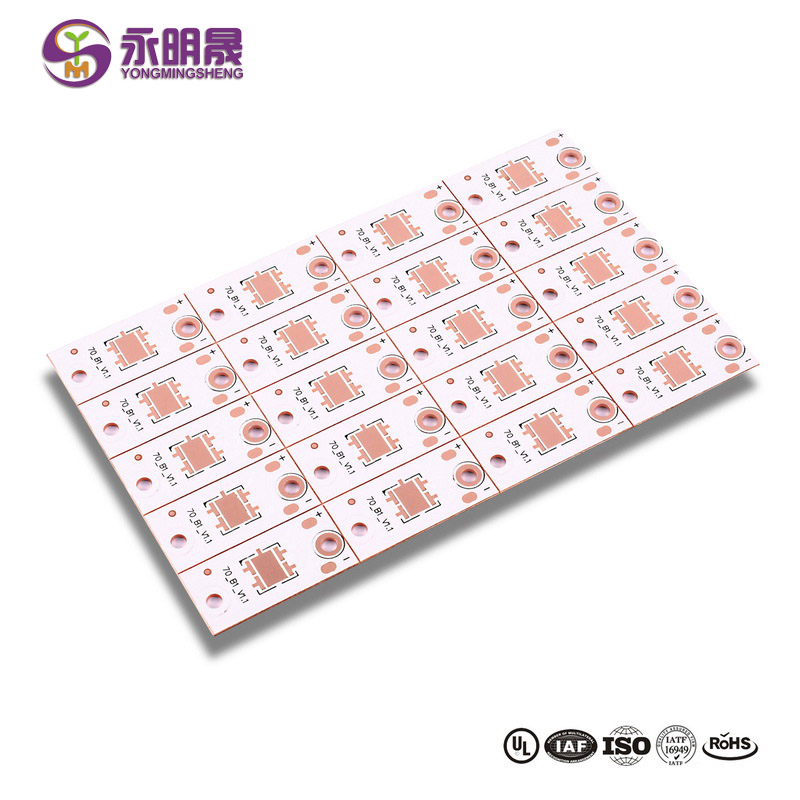

Looxyada wareegyada daabacan ee aluminiumka waxaa sidoo kale loo yaqaan PCB-yada saldhigga birta waxayna ka kooban yihiin laminates-ku-saleysan oo ay ku daboolan yihiin lakabyada wareegga wareegga birta. Waxay ka samaysan yihiin taargooyin alloy ah oo isku dhafan aluminium, magnesium iyo silumin (Al-Mg-Si). PCB-yada aluminiumku waxay bixiyaan dahaar koronto oo heer sare ah, awood kuleyl wanaagsan iyo waxqabadka mashiinada sare, waxayna kaga duwan yihiin PCB-yada kale dhowr siyaabood oo muhiim ah.

Lakabyada Aluminium PCB

Lakabka Saldhigga

Lakabkani wuxuu ka kooban yahay substrate aluminium aluminium ah. Isticmaalka aluminiumka ayaa ka dhigaya nooca PCB-ga doorasho heer sare ah oo loogu talagalay tignoolajiyada daloolka-god, ka dib laga hadlay.

lakabka dahaadhka kulaylka

Lakabkani waa qayb aad muhiim u ah PCB-ga. Waxay ka kooban tahay polymer dhoobo ah oo leh sifooyin viskoelastic ah oo aad u wanaagsan, iska caabin kulayl weyn leh oo ka difaaca PCB-ga culeysyada farsamada iyo kulaylka.

Lakabka wareegga

Lakabka wareeggu wuxuu ka kooban yahay xaashida naxaasta ah ee hore loo sheegay. Guud ahaan, soosaarayaasha PCB waxay isticmaalaan foil-ka naxaasta ah oo u dhexeeya hal ilaa 10 wiqiyadood.

Lakabka DIELECTIC

Lakabka dielectric ee dahaarka wuxuu nuugaa kulaylka marka hadda uu dhex socdo wareegyada. Tan waxaa loo wareejiyaa lakabka aluminium, halkaasoo kulaylku kala firdhiyo.

Gaaritaanka iftiinka ugu sarreeya ee suurtogalka ah waxay keenaysaa kulayl kordhay. PCB-yada leh caabbinta kulaylka oo hagaagtay waxay kordhiyaan nolosha alaabtaada dhammaatay. Soo-saare u qalma ayaa ku siin doona ilaalin sare, yaraynta kulaylka iyo isku halaynta qayb. Markay tahay YMS PCB, waxaanu ilaalinayna heerarka aadka u sarreeya iyo tayada mashaariicdaadu u baahan yihiin.

Baro wax badan oo ku saabsan alaabta YMS

Dadku sidoo kale way weydiiyaan

Waqtiga boostada: Jan-20-2022