Factory Customized China High Lumens SMD2835 LED Flexible Strip 196LED/M Ra80 15mm PCB

We have been convinced that with joint efforts, the small business between us will bring us mutual benefits. We will guarantee you merchandise top quality and competitive selling price for Factory Customized China High Lumens SMD2835 LED Flexible Strip 196LED/M Ra80 15mm PCB, Now we have established steady and long business relationships with customers from North America, Western Europe, Africa, South America, more than 60 countries and regions.

We have been convinced that with joint efforts, the small business between us will bring us mutual benefits. We will guarantee you merchandise top quality and competitive selling price for China LED Strip Light, LED Flexible Strip, Meanwhile, we’re building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products and solutions, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

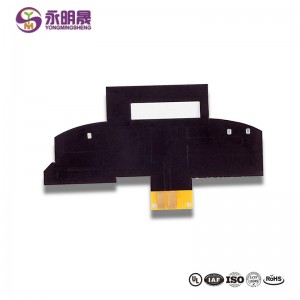

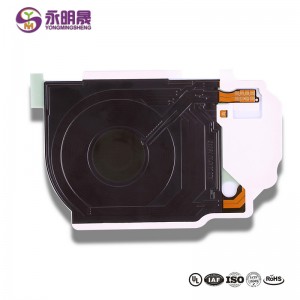

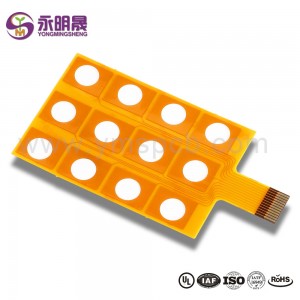

When circuits are too complex for single layer wiring or copper foil is needed for grounding shielding, double-layer or even multilayer boards are needed. The most typical difference between a laminate and a monolayer is the addition of a through-hole structure to connect the layers of copper foil. General substrate + transparent adhesive + copper foil the first processing process is the production of holes. First in the substrate and copper foil drilling, cleaning and plating a certain thickness of copper, and then through the hole is finished. And the next process is almost identical to that of a single board.