Factory wholesale Single Layer Fpc - 4Layer High Tg Board – Yongmingsheng

Factory wholesale Single Layer Fpc - 4Layer High Tg Board – Yongmingsheng Detail:

HASL (Eutectic; 63 percent Tin to 37 percent Pb)

▪ Usual coating thickness is 0.8 µm (0.000003 in) to 5 µm (0.0002 in); dependent upon the design

▪ Very good ability for soldering

▪ 0.635 mm (0.025 in) surface mount pitch or greater ability

▪ 0.75mm (0.030 in) is the minimum board thickness ability

▪ Adequate shelf life

High Tg refers to high heat resistance.Generally, the boards of Tg are over 130 degrees, high Tg is generally greater than 170 degrees, and medium Tg is about greater than 150 degrees. Generally, PCB printed boards with Tg≥170℃ are called high Tg printed boards.

With the rapid development of the electronic industry, especially the electronic products represented by the computer, towards the development of high function and high multi-layer, the higher heat resistance of PCB substrate material is needed as an important guarantee.

With the emergence and development of high density installation technology represented by SMT and CMT, PCB is more and more inseparable from the support of high heat resistance of substrate in the aspects of small aperture, fine wiring and thin type.

With the improvement of Tg of substrate, the heat resistance, moisture resistance, chemical resistance and stability of PCB will be improved.

The higher the TG value, the better the temperature resistance of the plate. Therefore, in many lead-free processes, high TG is more widely used.

The critical temperature at which the substrate melts from a solid state to a rubber-like fluid is called the Tg point or the melting point

The higher the Tg point is, the higher the temperature requirement is when the plate is pressed together, and the pressed plate will be hard and brittle. To some extent, the quality of mechanical drilling (if any) in the later process and the electrical characteristics during use will be affected

Tg point is the highest temperature (℃) at which the substrate remains rigid.That is to say, under high temperature, common PCB substrate materials not only produce softening, deformation, melting and other phenomena, but also show in the mechanical and electrical characteristics of the sharp decline

Generally, the Tg plate is more than 130 degrees, the high-tg is generally greater than 170 degrees, and the medium Tg is about more than 150 degrees.

With the improvement of Tg of substrate, the heat resistance, moisture resistance, chemical resistance and stability of PCB will be improved.

Searches related to High Tg Board:

1、10 Layer High Tg Hard Gold HDI Board

2、10 Layer (4OZ) High Tg Hard Gold (BGA) Board

3、10 Layer High Tg ,Hard Gold ,HDI Board

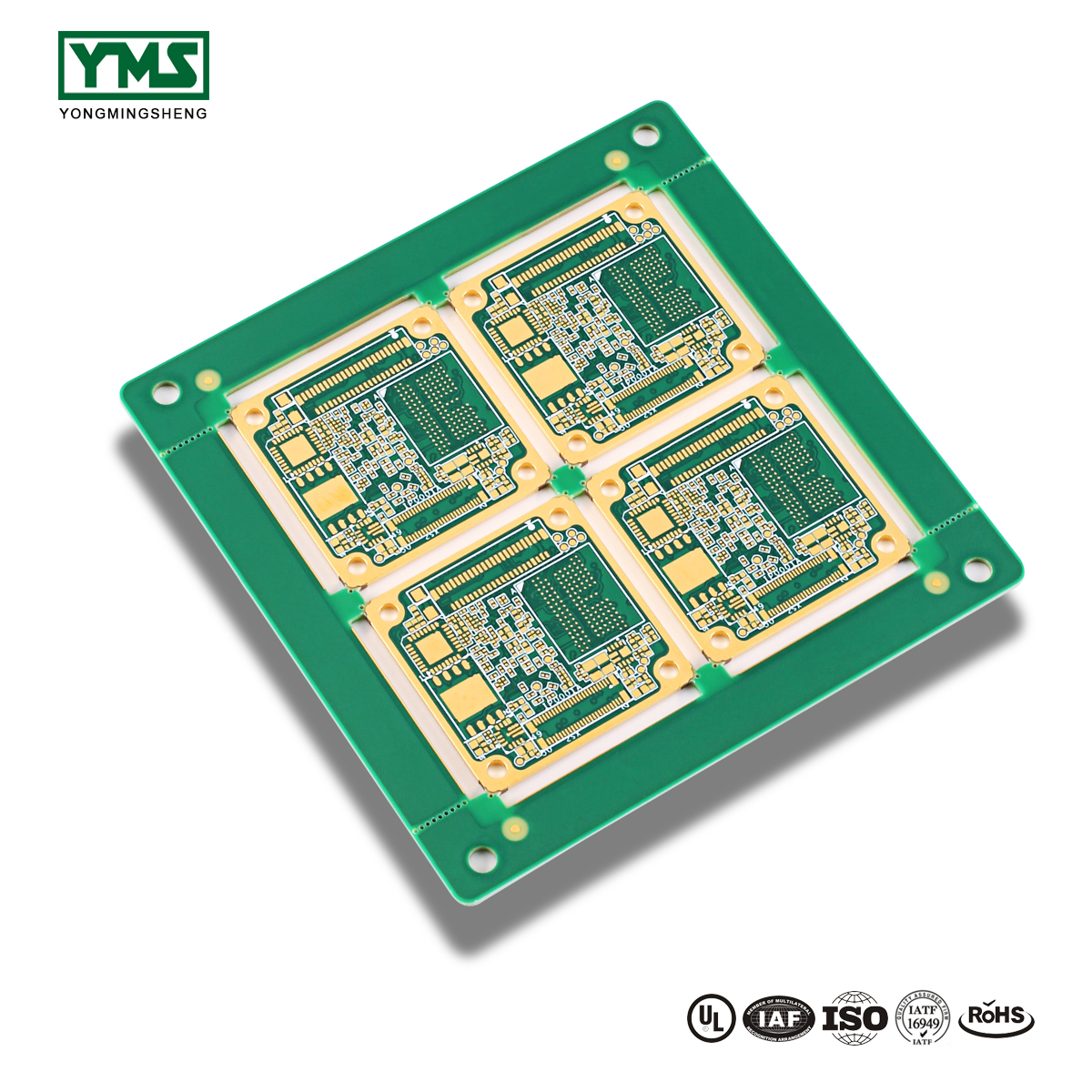

Product detail pictures:

Related Product Guide:

General Micro Systems Launches Apex, the Highest Performance Upgradeable Secure Server under ITAR Control | Rigid-Flexible Pcb

Global PCB Board Market Deep Analysis 2019-2027: TTM Technologies, Daeduck Group, Sumitomo Denko, Tripod, Nippon Mektron | 1.2m 2layer Led Pcb

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for Factory wholesale Single Layer Fpc - 4Layer High Tg Board – Yongmingsheng , The product will supply to all over the world, such as: Portugal, Poland, Thailand, Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!