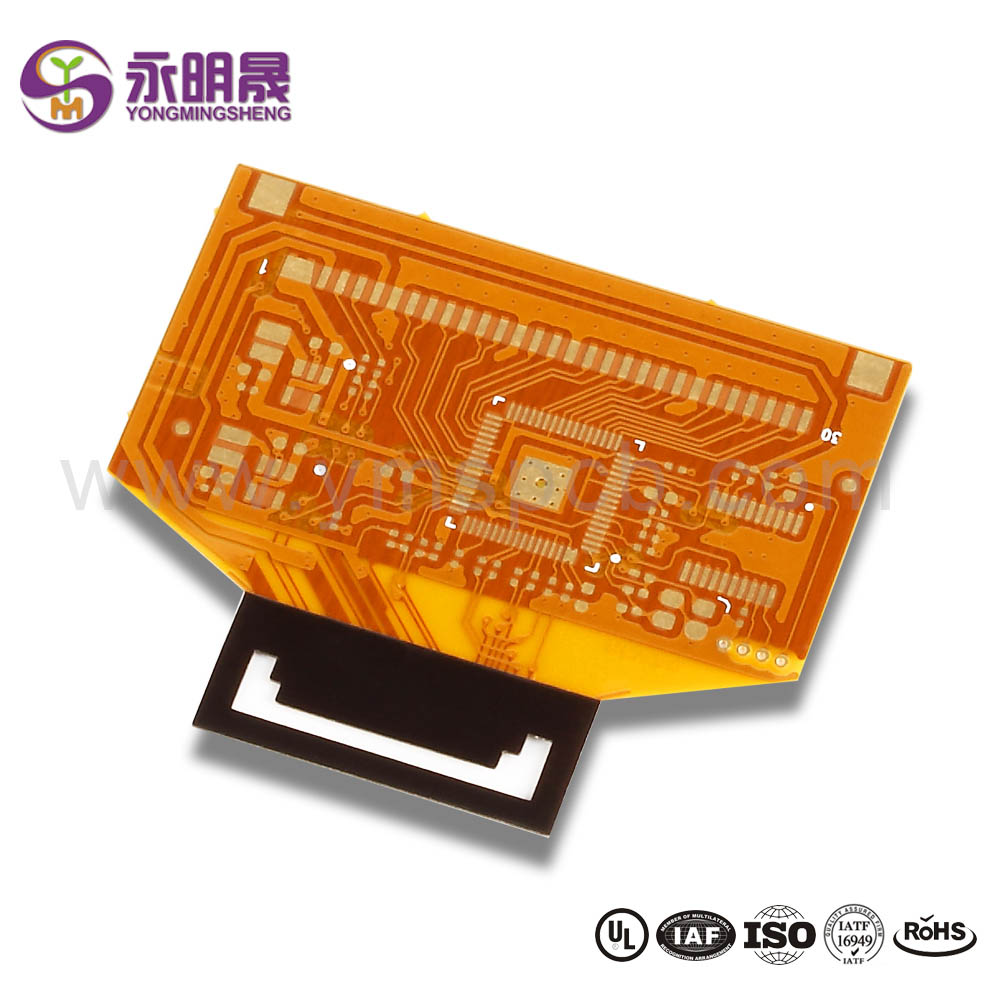

Lowest Price China Flexible Printed Circuit Board (FPC PCB)

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for China Cheap price China Mini LED Printed Circuit Board, Our corporation warmly welcome good friends from everywhere in the earth to visit, investigate and negotiate organization.

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for China PCB, Screen, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The things to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they’re created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

Flexible Circuit Board process:Plating Through-Hole

Metallization of through-holes.

After drilling, layers have not been connected yet.Flexible pcb manufacturer need to create a conductive layer on the wall of the holes.The plating through-hole processes are just for PCB with two or more layers.

When circuits are too complex for single layer wiring or copper foil is needed for grounding shielding, double-layer or even multilayer boards are needed. The most typical difference between a laminate and a monolayer is the addition of a through-hole structure to connect the layers of copper foil. General substrate + transparent adhesive + copper foil the first processing process is the production of holes. First in the substrate and copper foil drilling, cleaning and plating a certain thickness of copper, and then through the hole is finished. And the next process is almost identical to that of a single board.