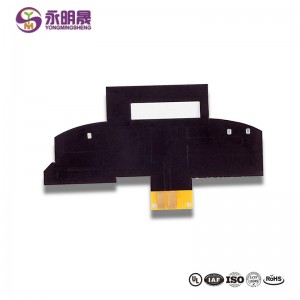

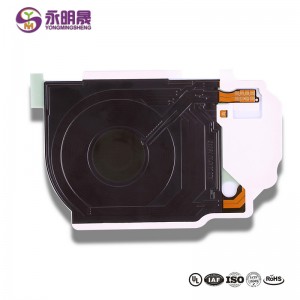

Factory For China High Quality Flexible & Rigid Printed Circuit Board PCBA Manufacturer

To meet the customers’ over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for Factory For China High Quality Flexible & Rigid Printed Circuit Board PCBA Manufacturer, Trust us, you can locate a better remedy on car elements industry.

To meet the customers’ over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for China PCB, Circuit Board, You can always find the products and solutions you need to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We’re looking forward to work with you for a win-win situation.

What is a FPC?

Flexible Printed Circuit (FPC) is a technology developed by the United States in the 1970s to develop space rocket technology, which is based on polyester film and polyimide as base material made of a kind of with high reliability, excellent rendition of flexible printed circuit. Through embedding circuit design in the flexible thin plastic sheet make the pile embedded in narrow and limited space a large number of precision components, so that a flexible printed circuit is formed.

This kind of circuit can be bent and folded at will, which is light in weight, small in volume, good in heat dissipation and easy to install.

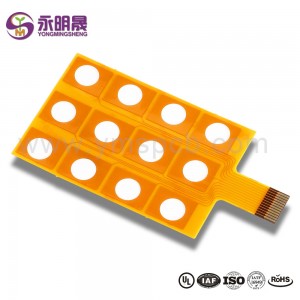

Different Copper Foils Used in Flex Circuit

[Process Description]

The copper foil used in the FPC depends on the applications.

[General Procedure]

Copper foil material used in normal PCB has two types, electrodeposited copper foil and rolled copper foil, and used in different applications.Rolled copper foil is used in dynamic flexible production for its compactness and flexure resistance.

Electrodeposited copper foil is used in non-dynamic flexure applications Rolled copper foil manufacturing process will create much stress and then need annealing.After annealing, rolled copper foil has suitable grain structure to prevent crack propagation.That’s why it has flexure resistance.