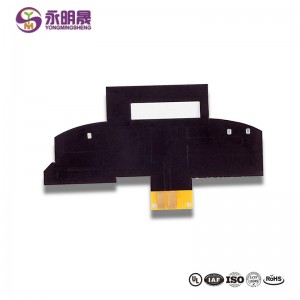

Renewable Design for China Shenzhen Customized Fr4 FPC Flexible Circuit Board Customized PCB Manufacturing PCB

We always do the job to be a tangible team to ensure that we can present you with the very best good quality as well as the best cost for Renewable Design for China Shenzhen Customized Fr4 FPC Flexible Circuit Board Customized PCB Manufacturing PCB, We also make sure that your assortment will be crafted while using the optimum quality and dependability. Make sure you experience totally free to make contact with us for more information and facts.

We always do the job to be a tangible team to ensure that we can present you with the very best good quality as well as the best cost for China Circuit Board, Pcb, With a wide range, good quality, reasonable prices and stylish designs, our products and solutions are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

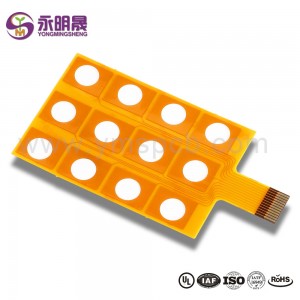

Flexible Circuit Board process:Plating Through-Hole

Metallization of through-holes.

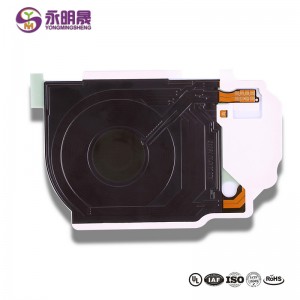

After drilling, layers have not been connected yet.Flexible pcb manufacturer need to create a conductive layer on the wall of the holes.The plating through-hole processes are just for PCB with two or more layers.

When circuits are too complex for single layer wiring or copper foil is needed for grounding shielding, double-layer or even multilayer boards are needed. The most typical difference between a laminate and a monolayer is the addition of a through-hole structure to connect the layers of copper foil. General substrate + transparent adhesive + copper foil the first processing process is the production of holes. First in the substrate and copper foil drilling, cleaning and plating a certain thickness of copper, and then through the hole is finished. And the next process is almost identical to that of a single board.

People also ask: