High TG FR4 Material PCB BGA Pitch 0.65mm Wholesale | YMS PCB

Aluminum PCB is one of the most widely used metal core PCBs, also called as MC PCB, aluminum-clad, or insulated metal substrate, etc.

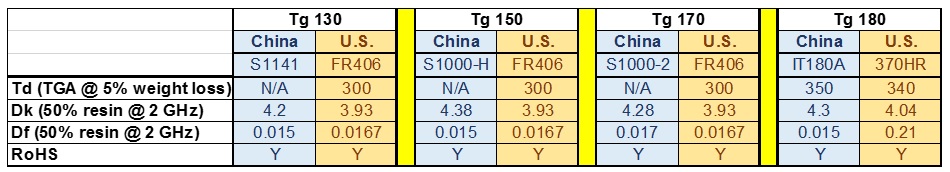

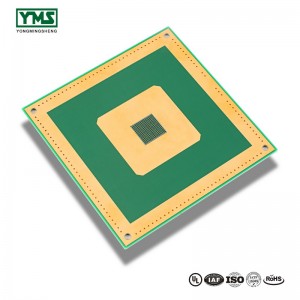

If working temperature of your product is higher than normal (130-140C), then have to use high Tg material which is > 170C. and popular PCB high value are 170C, 175C, and 180C.

Aluminum PCB is one of the most widely used metal core PCBs, also called as MC PCB, aluminum-clad, or insulated metal substrate, etc. The base structure of the aluminum PCB has no much different from other PCBs. The aluminum base is its notable feature. Usually, aluminum PCB includes four layers: a substrate layer (aluminum layer), a dielectric layer (insulating layer), a circuit layer (copper foil layer), and an aluminum base membrane (protective layer).

As we all know, high-temperature situations will appear when the electronics are operating at high speeds. If the thermal energy cannot be directed away quickly, the components which under high temperature may be softened, deformation, parameters changed, and performance changed, even present safety risks. Aluminum bases can remove the heat from components very soon, which allows high-density and high-power PCB designs to be achieved. The heat dissipation efficiency of aluminum PCB is ten times higher than the fiber-glass base PCBs.

If you have the problem of thermal dissipation in your PCB design, the aluminum board should be your primary consideration. YMS provides all types of aluminum PCBs including single-sided aluminum PCBs, multilayer aluminum PCBs, hybrid aluminum PCBs, flexible aluminum PCBs, through-hole aluminum PCBs, etc. Other categories, such as universal aluminum PCB, high thermal-conductive aluminum PCB, and high-frequency aluminum PCBs are also available. Please do not hesitate to contact us if you need more details about our aluminum PCBs.

High-TG PCB Advanced Circuits Specification

The glass transition temperature of PCB, referred to as “Tg”, indicates the point at which the PCB material will begin to transform. If the operating temperature exceeds the designated Tg value, the board will begin to change from a solid to a liquid state, which is likely to have an adverse effect on its ability to function.

Standard PCBs are manufactured with materials offering a TG value of 140°C, which can withstand an operating temperate of 110°C. While this may not be suitable for extreme-temperature processes that are commonplace in applications such as automotive, industrial or high-temperature electronics. In these situations, a PCB made from FR-4 High TG material can often provide the best solution.

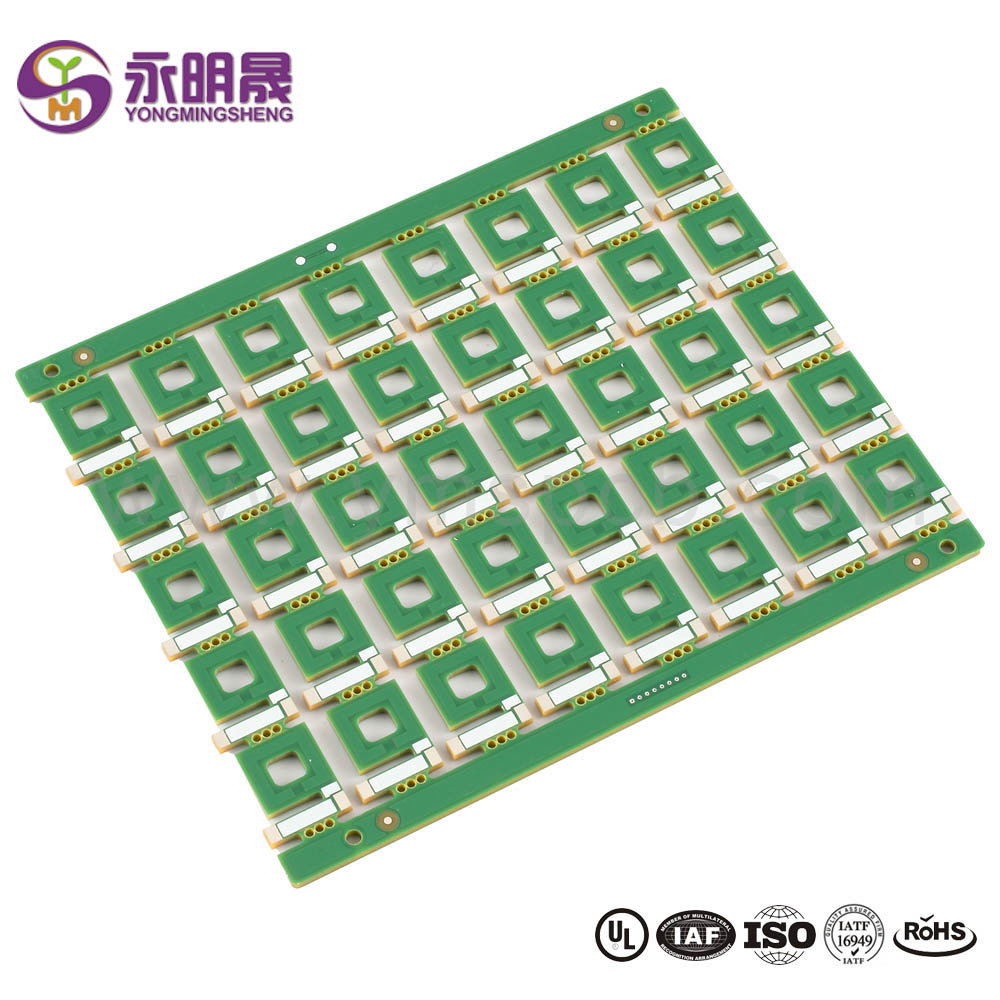

YMS High Tg PCB manufacturing capabilities:

|

YMS High Tg PCB manufacturing capabilities overview |

||

| Feature | capabilities | |

| Layer Count | 3-60L | |

| Available Multilayer PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 TG 180°Mix etc. | |

| High Speed Material such as M7NE and FR4 TG 180°Mix etc. | ||

| Thickness | 0.3mm-8mm | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

Learn more about YMS products

Read more news

What is Thermal Clad?

Thermal Clad Printed Circuit Boards are fabricated by either an additive process or subtractive process. An additive process is one where patterns are formed by Copper plating. A subtractive process is one which the patterns are formed by etching away copper foil selectively.

What is clad in PCB?

the PCB substrates in PCB manufacturing,It is the basic material for manufacturing circuit boards

What are the 3 types of PCB?

rigid PCB;flex PCB;rigid-flex pcb

What are thermal management materials?

Thermal management materials are a range of different product types designed to effectively dissipate heat in electronic applications. They are composite systems that enable efficient heat transfer within components.