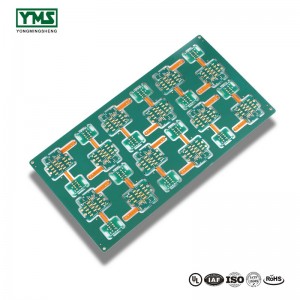

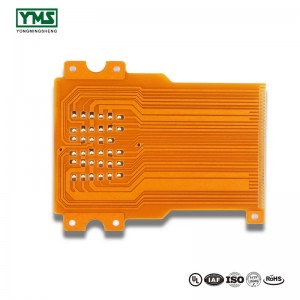

Excellent quality Flex-rigid Flexible Pcb Board Fpc

“Control the standard by the details, show the power by quality”. Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for Excellent quality Flex-rigid Flexible Pcb Board Fpc, Sincerely stay up for serving you from the in the vicinity of future. You are sincerely welcome to go to our company to talk company face to face with each other and create long-term co-operation with us!

“Control the standard by the details, show the power by quality”. Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for Flex-Rigid Pcb, Flexible Pcb, Fpc, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer’s wider and higher requirement in recent years. We’re looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Flex-Rigid basic production process:

First, a hard plate having a first line layer and a plurality of soft plates having a second line layer are provided. The hard plate comprises a predetermined removal area and a plurality of hard plate units.

Next, cutting lines of a plurality of predetermined exposed soft plate areas are cut between these hard plate units and the predetermined removal area.

After that, the first line layer on the hard board and the second line layer on the soft board are electrically conducted by combining these soft boards with an adhesive layer and forming multiple conducting holes in the hard board and these soft boards. And each of these cutting lines along the hard plate breaks the intended removal area to reveal the individual soft plates and to shape the hard plate elements.

Finally, each flexible plate is folded in half along its own multiple folding lines so that the rigid plate elements are extended and arranged in one direction.

Searches related to HDI PCB

2、10 Layer (4OZ) High Tg Hard Gold (BGA) Board