Factory Cheap Electronic Smt Fr4 Rigid Metal Pcb Assembly Metal Detector Pcb Circuit Board And Pcb Copy

We have now advanced machines. Our merchandise are exported towards the USA, the UK and so on, enjoying a good reputation amongst consumers for Factory Cheap Electronic Smt Fr4 Rigid Metal Pcb Assembly Metal Detector Pcb Circuit Board And Pcb Copy, We attend seriously to produce and behave with integrity, and by the favor of customers at home and abroad in the xxx industry.

We have now advanced machines. Our merchandise are exported towards the USA, the UK and so on, enjoying a good reputation amongst consumers for Metal Detector Pcb Circuit Board, Oem Electronic Circuit Board Assembly, Smt Fr4 Rigid, Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

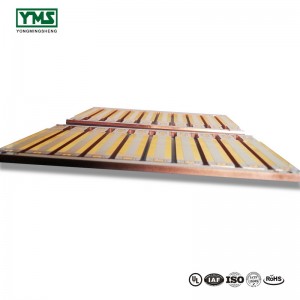

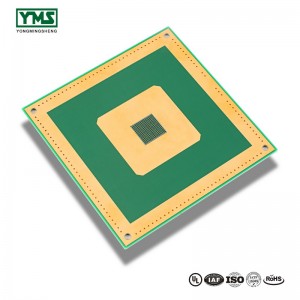

The main reasons for using copper base boards

1. Good heat dissipation:

At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability:

Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause:

Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

You May Like:

1、Application characteristics of aluminum PCB

2、Copper plating process of PCB outer layer (PTH)

3、Copper clad plate and aluminum substrate four major differences